Preparation method of flavored beef tallow

A kind of butter and flavor technology, which is applied in the direction of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc. It can solve the problems of difficult removal, reduce the peroxide value of butter, and reduce the production cost of butter, so as to prevent Effects of over-oxidation, enrichment of nutrients, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

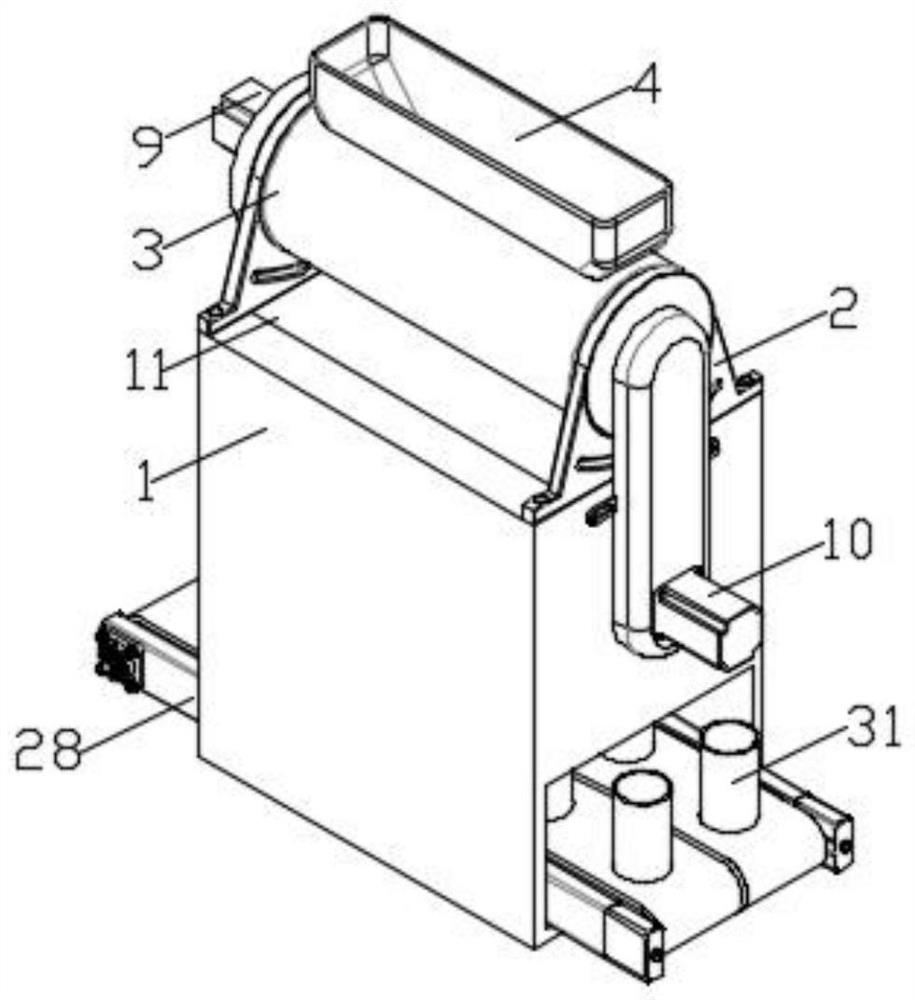

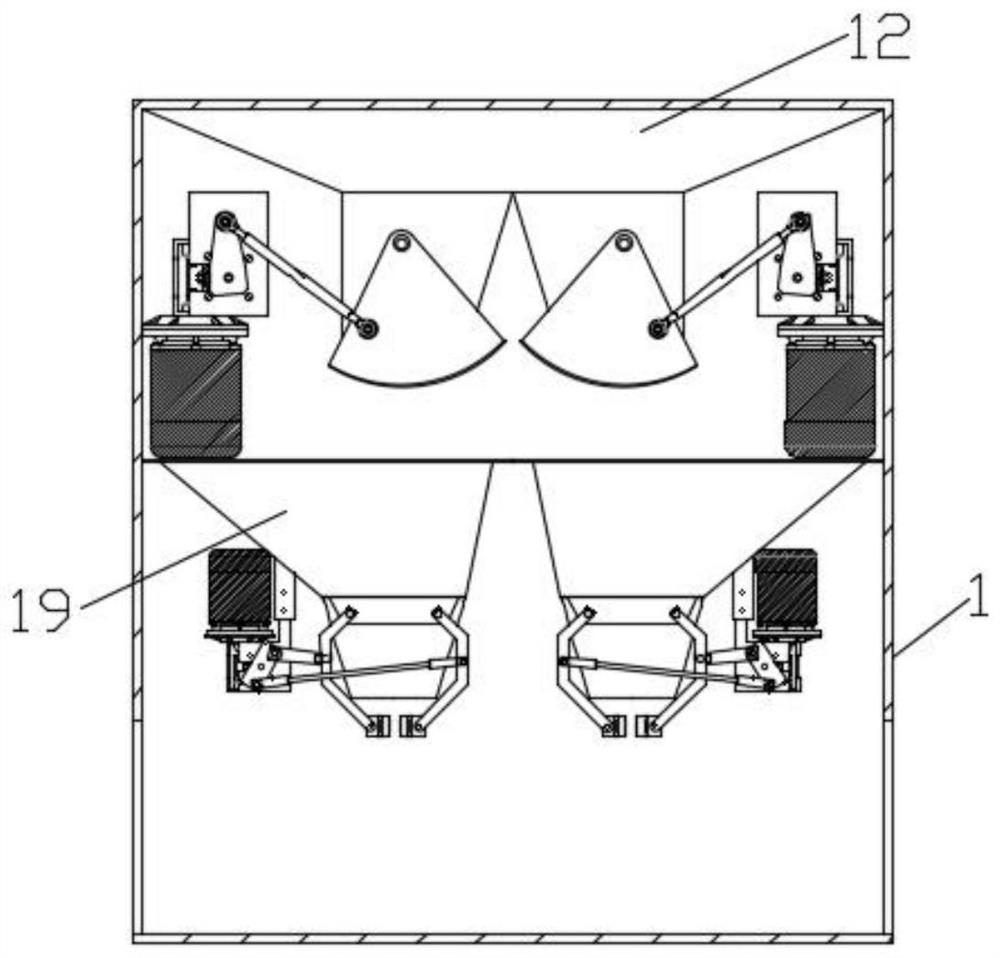

Image

Examples

Embodiment 1

[0038] A preparation method of flavored butter, comprising the steps of:

[0039] Step 1: Crude oil preparation: select fresh, non-rotten and non-deteriorated crude butter, chop it and add it to the melting oil tank, slowly raise the temperature to 75°C to melt all the crude butter, and obtain the first-grade treated oil;

[0040] Step 2: Add apple slurry and NaCO solution to the primary treatment oil, control the temperature at 78°C, and under the condition of ultrasonic power of 500W, keep it warm for 30 minutes and then vacuum dry to obtain the secondary treatment oil;

[0041] Step 3: Filter the secondary treated oil through 100 mesh to remove the impurities and obtain the tertiary treated oil;

[0042] Step 4: After the three-stage treated oil is decolorized by the tubular decolorizer and deodorized by the deodorization tower, the fourth-stage treated oil is obtained;

[0043] Step 5: At 70°C, the four-stage treated oil passes through filter cloths of 200 mesh, 300 mesh ...

Embodiment 2

[0048] A preparation method of flavored butter, comprising the steps of:

[0049] Step 1: Crude oil preparation: select fresh, non-rotten and non-deteriorated crude butter, chop it and add it to the melting oil tank, slowly raise the temperature to 80°C to melt all the crude butter, and obtain the primary treatment oil;

[0050] Step 2: Add apple slurry and NaCO solution to the primary treatment oil, control the temperature at 82°C, and under the condition of ultrasonic power of 800W, keep it warm for 45 minutes and then vacuum dry to obtain the secondary treatment oil;

[0051] Step 3: Filter the secondary treated oil through 200 mesh to remove the impurities to obtain the tertiary treated oil;

[0052] Step 4: After the three-stage treated oil is decolorized by the tubular decolorizer and deodorized by the deodorization tower, the fourth-stage treated oil is obtained;

[0053] Step 5: At 80°C, the four-stage treated oil passes through filter cloths of 200 mesh, 300 mesh and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com