Efficient dephosphorization oxygen lance spray head and blowing technology

A technology of oxygen lance nozzle and oxygen lance, which is applied in the field of iron and steel metallurgy, to prevent the formation of dry slag, achieve a significant dephosphorization effect, and improve the dephosphorization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

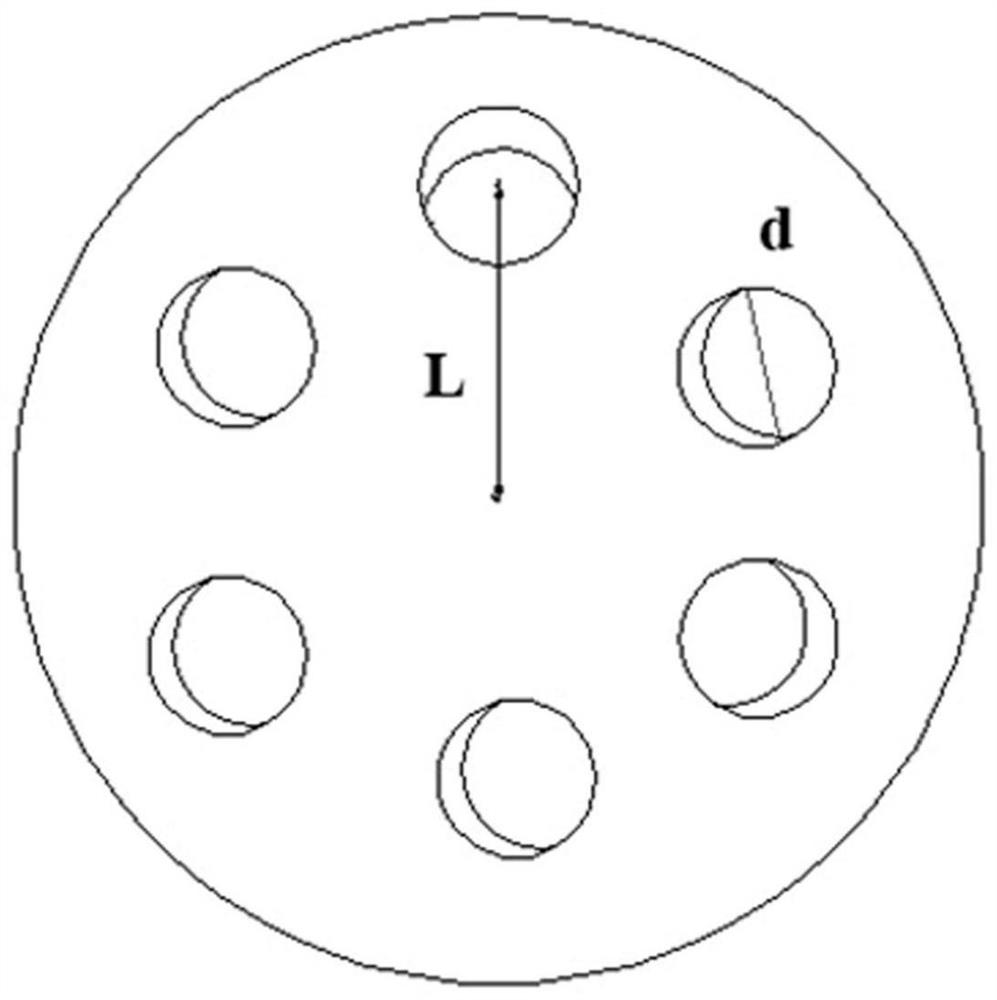

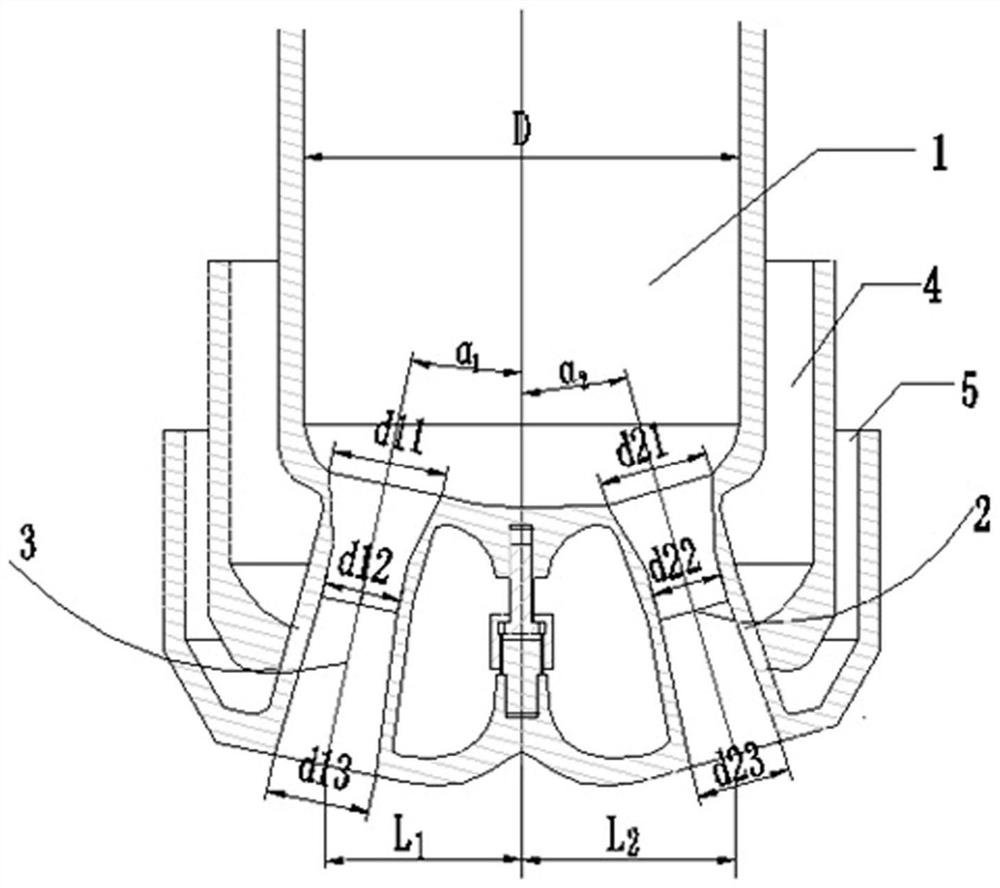

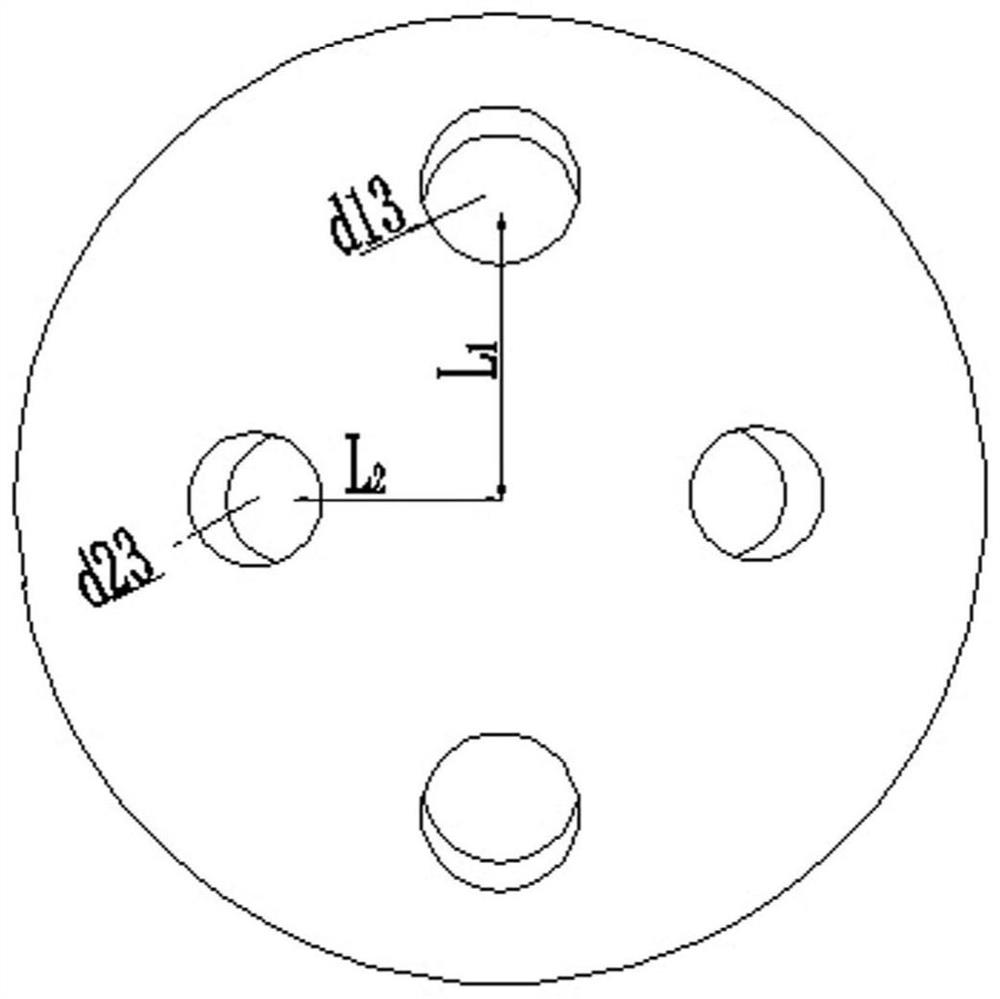

Image

Examples

Embodiment 1

[0056] In order to verify the obvious effect of the present invention compared with the traditional oxygen lance nozzle, a comparative experiment between the high-efficiency dephosphorization oxygen lance nozzle and the traditional oxygen lance nozzle under the same smelting conditions was carried out. The specific dimensions of the two oxygen lance nozzles are shown in Table 1.

[0057] Table 1 Geometric parameters of traditional oxygen lance nozzle and high-efficiency dephosphorization oxygen lance nozzle for 260t converter

[0058]

[0059] During the experiment period, the steel produced is automobile plate, the amount of molten iron is 260t, the amount of scrap steel is 30-40t, the oxygen pressure of the main pipe is 1.4MPa, the working oxygen pressure is 1.0MPa, and the flow rate of oxygen supply is 54000Nm3 / h. The position of the blowing gun varies from 2.6m to 3.1m, the position of the process gun varies from 2.4m to 2.7m, and the position of the carbon pulling gun v...

Embodiment 2

[0070] Compare "a single-channel double-structure oxygen lance nozzle and blowing process". The purpose of this technology 1) single-channel double-structure oxygen lance nozzle and blowing process is to improve the jet flow intensity, ensure the stirring effect of the jet flow oxygen lance on the molten pool, and reduce the occurrence of splashing at the same time. The purpose of the invention is to increase the amount of spatter in the furnace generated after the jet flow of the nozzle of the oxygen lance interacts with the molten pool. 2) The applicable steel types of the two are different. The single-channel double-structure oxygen lance nozzle has wider applicability, but for steel types that require high dephosphorization rate, the dephosphorization effect is not much different from that of the traditional oxygen lance. The stirring effect of the high-efficiency dephosphorization oxygen lance on the molten pool may not be as good as that of the single-channel dual-struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com