Ceftazidime combined powder injection and preparation method and product specification thereof

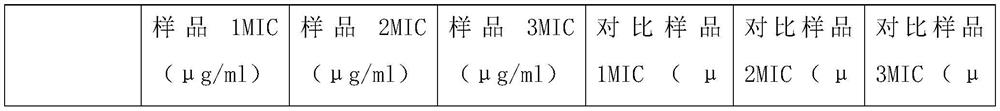

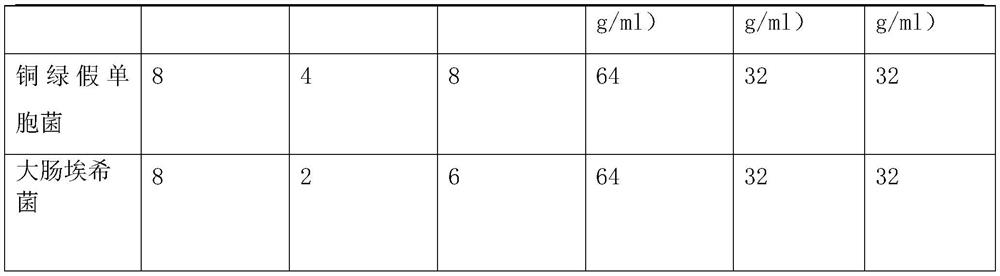

A technology for ceftazidime and powder injection, which is applied in the field of ceftazidime combined powder injection and preparation thereof, can solve the problems of easy occurrence of allergic reaction, poor purification effect, rapid change of impurities, etc., and achieves good curing effect, good bacteriostatic effect, The effect of reducing the number of white blood cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The formula includes: 8.7 g of ceftazidime nanoparticles, 6.4 g of chitosan nanoparticles, 22 g of liposome vesicles, 0.48 g of arginine, and 5.63 g of anhydrous sodium carbonate in parts by mass. Ceftazidime nanoparticles are granulated in a nanoparticle preparation company with raw materials with a purity of 98.98%, and chitosan nanoparticles are granulated in a nanoparticle preparation company with high-purity raw materials.

[0033] Prepare samples as follows:

[0034] Including the following steps:

[0035] Step 1, preparing liposome vesicles;

[0036] Dissolve phospholipids and cholesterol in a mixed solvent of chloroform and methanol at a mass ratio of 2:1, evaporate to obtain a phospholipid film, then add PBS buffer and mannitol to the phospholipid film, and then sonicate to obtain liposome vesicles.

[0037] Step 2, preparing liposome nanoparticles;

[0038] Adding ceftazidime nanoparticles to liposome vesicles to obtain a first mixed solution, mi...

Embodiment 2

[0042] Example 2: The formula includes: 8.7 g of ceftazidime nanoparticles, 6.4 g of chitosan nanoparticles, 22 g of liposome vesicles, 0.69 g of arginine, and 3.24 g of anhydrous sodium carbonate in parts by mass. Ceftazidime nanoparticles are granulated in a nanoparticle preparation company with raw materials with a purity of 98.98%, and chitosan nanoparticles are granulated in a nanoparticle preparation company with high-purity raw materials.

[0043] Prepare samples as follows:

[0044] Including the following steps:

[0045] Step 1, preparing liposome vesicles;

[0046] Dissolve phospholipids and cholesterol in a mixed solvent of chloroform and methanol at a mass ratio of 2:1, evaporate to obtain a phospholipid film, then add PBS buffer and mannitol to the phospholipid film, and then sonicate to obtain liposome vesicles.

[0047] Step 2, preparing liposome nanoparticles;

[0048] Adding ceftazidime nanoparticles to liposome vesicles to obtain a first mixed solution, mi...

Embodiment 3

[0052] Example 3: The formula includes: 8.7 g of ceftazidime nanoparticles, 6.4 g of chitosan nanoparticles, 22 g of liposome vesicles, 1.24 g of arginine, and 5.63 g of arginine in parts by mass. Ceftazidime nanoparticles are granulated in a nanoparticle preparation company with raw materials with a purity of 98.98%, and chitosan nanoparticles are granulated in a nanoparticle preparation company with high-purity raw materials.

[0053] Prepare samples as follows:

[0054]Including the following steps:

[0055] Step 1, preparing liposome vesicles;

[0056] Dissolve phospholipids and cholesterol in a mixed solvent of chloroform and methanol at a mass ratio of 2:1, evaporate to obtain a phospholipid film, then add PBS buffer and mannitol to the phospholipid film, and then sonicate to obtain liposome vesicles.

[0057] Step 2, preparing liposome nanoparticles;

[0058] Adding ceftazidime nanoparticles to liposome vesicles to obtain a first mixed solution, mixing the first mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com