Method for epitaxially growing GeSi quantum dots

A technology of quantum dots and epitaxy, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of large quantum dots, difficulty in preparation, and growth of quantum dots, etc. The method is simple and practical, consistent in size and uniform in distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

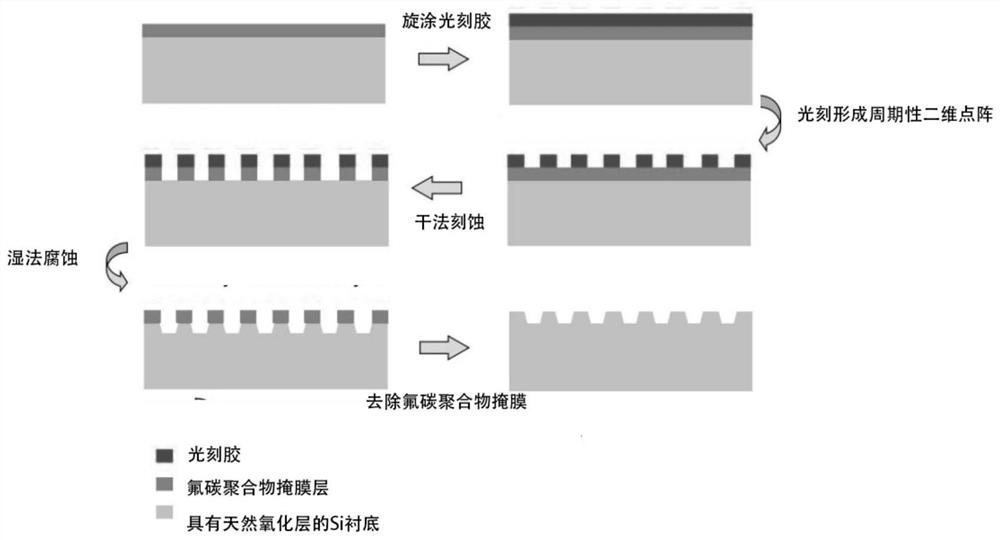

[0037] Step 1) Fabricate a truncated inverted pyramid pattern on a silicon pattern substrate.

[0038] Specific reference image 3 The flow chart of the preparation of the truncated inverted pyramid figure is shown.

[0039] First, an N-type single crystal silicon wafer with a crystal orientation of (001) is selected as a substrate, and a silicon dioxide oxide layer of 6nm to 10nm is naturally present on the surface, and a photoresist is spin-coated on it. Then, a two-dimensional photoresist lattice with a period of 600nm and a size of 240nm was prepared by an interference exposure system. Subsequently, the silicon dioxide layer was dry etched by RIE, the etching gas was CHF 3 With Ar gas, transfer the photoresist pattern to the silicon dioxide layer, and at the same time form a fluorocarbon polymer mask for subsequent wet etching. The wet etching uses KOH etching solution, the etching rate is 20nm / min, and the fluorine The carbon polymer is used as a wet etching mask to pr...

Embodiment 2

[0046] Make the truncated inverted pyramid pattern on the silicon pattern substrate, its method is the same as embodiment 1. The period of the pattern substrate is 600nm, the side length of the top opening of the pattern is 300nm, and the bottom side length is 240nm, which is a truncated inverted pyramid pattern.

[0047] The graphics substrate is placed in the gaseous source MBE, and GeSi quantum dots with a lateral size of 30nm and a height of 10nm are epitaxially grown on the truncated inverted pyramid graphics substrate, and the quantum dots are distributed on the boundary line of the (111) plane.

[0048] Gaseous source MBE was used to grow GeSi quantum dots, and disilane (Si 2 h 6 ) and germane (GeH 4 ) as the gas source of silicon and germanium respectively, control disilane flow rate to 2.5 sccm, germane flow rate to 5 sccm, and growth temperature to 600°C. Under these conditions, the growth rate of GeSi quantum dots is 0.02nm / s, and the growth time is 70s. In this ...

Embodiment 3

[0051] Make the truncated inverted pyramid pattern on the silicon pattern substrate, its method is the same as embodiment 1. The period of the pattern substrate is 600nm, the side length of the top opening of the pattern is 300nm, and the bottom side length is 140nm, which is a truncated inverted pyramid pattern.

[0052] The graphics substrate is placed in the gaseous source MBE, and GeSi quantum dots with a lateral size of 80nm and a height of 40nm are epitaxially grown on the truncated inverted pyramid graphics substrate, and the quantum dots are distributed on the boundary line of the (111) plane.

[0053] Gaseous source MBE was used to grow GeSi quantum dots, and disilane (Si 2 h 6 ) and germane (GeH 4 ) as the gas sources of silicon and germanium respectively, control the disilane flow rate to 10 sccm, the germane flow rate to 15 sccm, and the growth temperature to 600°C. Under these conditions, the growth rate of GeSi quantum dots is 0.1nm / s, and the growth time is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com