Hollow foam autocatalytic electrode and preparation method thereof

A catalytic electrode, foam technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of limited specific surface area, complex components, and unfavorable industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

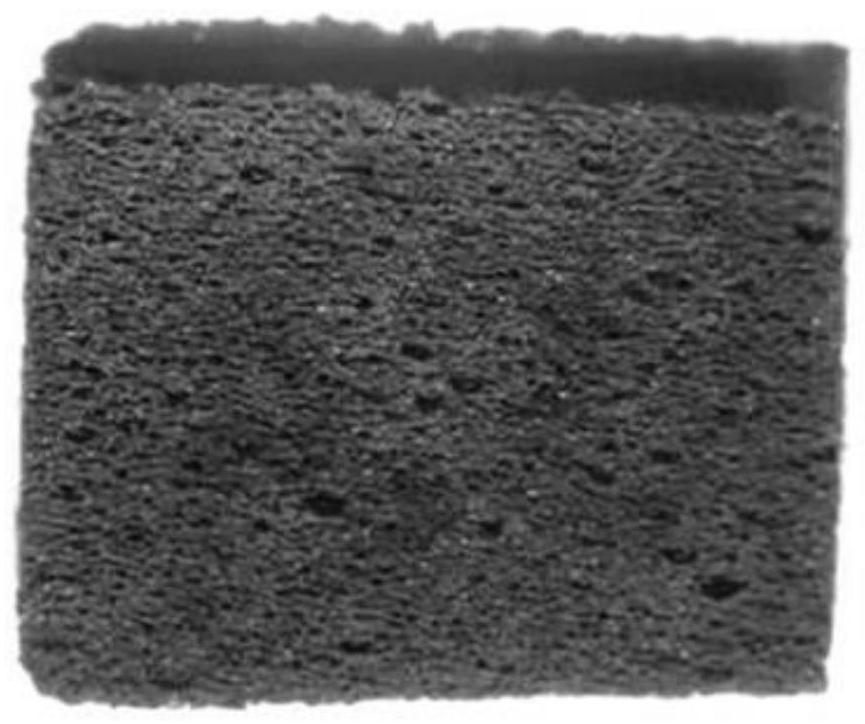

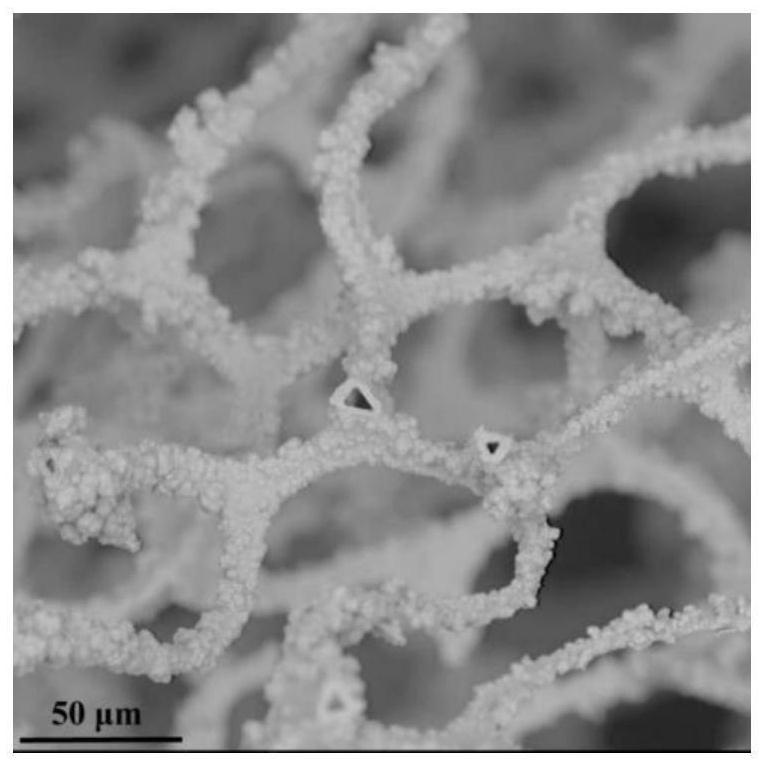

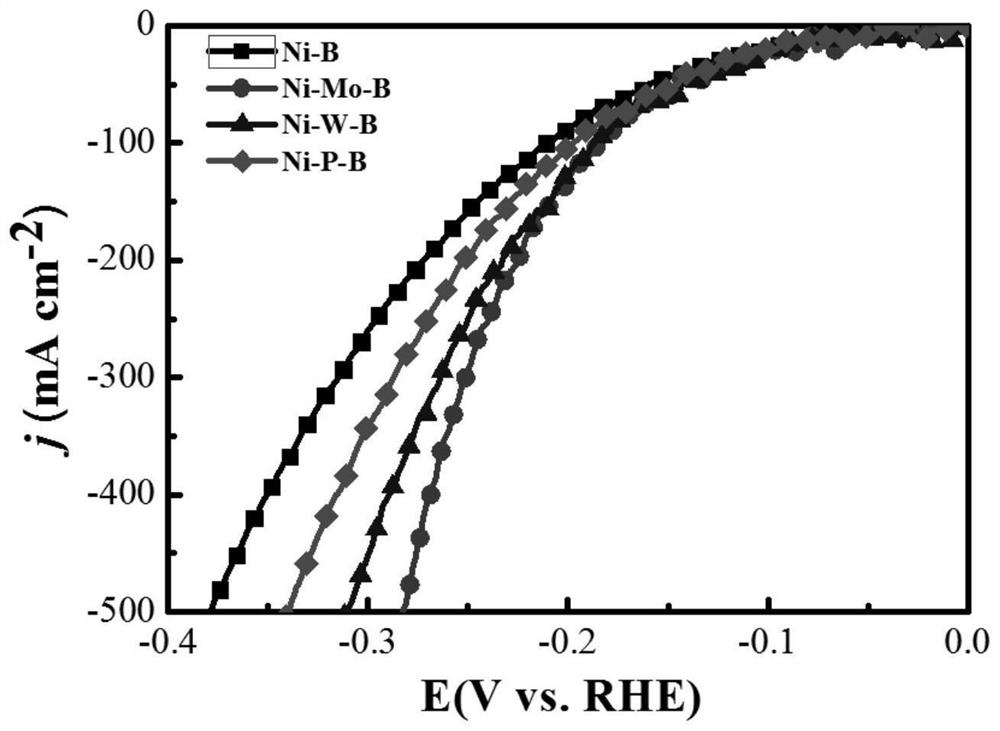

[0026] Embodiment 1, the preparation of Ni-B hollow foam autogenous electrode

[0027] (1) Activation of polymer foam matrix

[0028] The 1 cm × 1 cm × 0.15 cm melamine resin foam to be activated was completely submerged in 10 mL of 0.2 mol / L nickel sulfate solution, and 10 mL of 0.3 mol / L (CH 3 ) 4 NB 3 h 8 Stir evenly, and then heat the water bath to 40 °C to initiate the reaction. After 5 min of reaction, rinse the activated non-metallic substrate with deionized water.

[0029] (2) Configure the electroless plating solution containing Ni-B

[0030] The chemical plating solution raw material ratio and process conditions are shown in the table below. Dissolve 1.5 g of sodium sulfate and 2.5 g of sodium succinate in 100 mL of deionized water. After the ultrasonic solution is completely dissolved, add 2.5 g of nickel sulfate hexahydrate to form a stable complex solution; finally add 0.72 g of dimethylamine borane , when it is completely dissolved, the pH of the solution i...

Embodiment 2

[0038] Embodiment 2, the preparation of Ni-Mo-B hollow foam autogenous electrode

[0039] (1) Activation of polymer foam matrix

[0040] Completely immerse the 1 cm × 1 cm × 0.15 cm polyurethane foam to be activated in 10 mL of 0.2 mol / L nickel chloride solution, and add 10 mL of 0.5 mol / L KBH 4 Stir well, and after reacting for 5 min, rinse the activated non-metallic substrate with deionized water.

[0041] (2) Configure the electroless plating solution containing Ni-B

[0042]The chemical plating solution raw material ratio and process conditions are shown in the table below. To configure the electroless plating solution containing Ni-Mo-B, its raw material ratio and process conditions are shown in the table below. Sodium sulfate (1.5 g) and sodium succinate (2.5 g) were dissolved in deionized water (100 mL), and after ultrasonic dissolution was complete, nickel sulfate hexahydrate (2.5 g) and sodium molybdate (0.02 g) were added to form Stable complex solution; add dime...

Embodiment 3

[0050] Embodiment 3, the preparation of Ni-P-B hollow foam autogenous electrode

[0051] (1) Activation of polymer foam matrix

[0052] Completely immerse the 1 cm × 1 cm × 0.15 cm melamine resin foam to be activated in 10 mL of 0.2 mol / L nickel sulfate solution, and add 10 mL of 0.3 mol / L NaBH 4 Stir well, and after reacting for 5 min, rinse the activated non-metallic substrate with deionized water.

[0053] (2) Configure the chemical plating solution

[0054] The chemical plating solution raw material ratio and process conditions are shown in the table below. Sodium sulfate (1.5 g), sodium hypophosphite (0.1 g), and sodium succinate (2.5 g) were dissolved in deionized water (100 mL), and after ultrasonic dissolution was complete, nickel sulfate hexahydrate (2.5 g) was added, A stable complex solution is formed; finally add dimethylamine borane (0.72 g) and wait until it is completely dissolved, and the pH environment of the solution is about 8.0;

[0055] .

[0056] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com