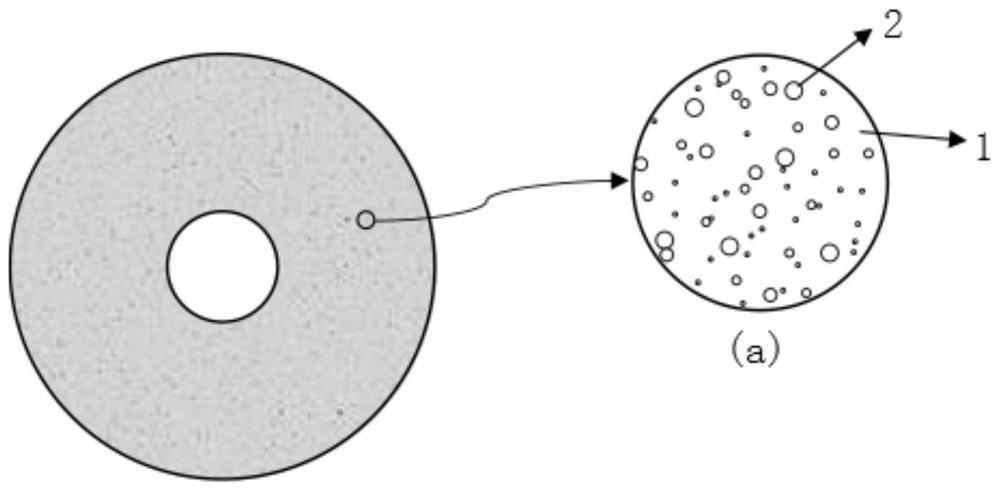

A kind of porous resin grinding disc and preparation method thereof

A porous resin and grinding disc technology, which is applied in the direction of grinding tools, grinding/polishing equipment, abrasives, etc., can solve the problems of high maintenance requirements, large loss of grinding discs, high cost, etc., and achieve easy transportation and installation, roughness Small, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 20g of water (water as pore-forming agent) and 100g of white carbon black to 1800g of polyurethane resin white material (polyether 303), add 200g of curing agent MOCA (3,3'-dichloro-4,4'-dichloromethane) Amino diphenylmethane), stir well with a high-speed mixer, then add 2100g of polyurethane resin black material (PAPI), stir well with a high-speed mixer, and then pour the mixture into a stainless steel mold with a diameter of 610mm, and quickly solidify at room temperature. Porous polyurethane resin disc.

[0027] The obtained porous polyurethane resin disk has a Shore hardness of 70D, and the proportion of pores is 15%.

[0028] A 2-inch sapphire wafer was ground using the porous polyurethane resin disk, and compared with the traditional resin copper disk. The test of the grinding rate uses a plane grinder SK-610Y with a pressure of 300g / cm 2 , the speed is 60rpm. The lapping liquid adopts a polycrystalline diamond lapping liquid with a particle size D50 of 6 μ...

Embodiment 2

[0033] Add 200g of polymer hollow microspheres and 200g of cerium oxide powder to 3600g of epoxy resin, stir well with a high-speed mixer, then add 500g of epoxy resin curing agent T31, stir well with a high-speed mixer, and pour the mixed slurry It was put into a stainless steel mold with a diameter of 610 mm and cured at 60° C. for 24 hours to form a porous epoxy resin disk.

[0034] The obtained porous epoxy resin disk has a Shore hardness of 60D, and the proportion of pores is 60%.

[0035] The porous epoxy resin disc was used to grind the copper sheet and compared with the traditional resin copper disc. The test of the grinding rate uses a plane grinder SK-610Y, the pressure is 200g / cm 2 , the speed is 60rpm. The grinding liquid adopts single crystal diamond grinding liquid with a particle size D50 of 5 μm.

[0036] Grinding Disc Type Grinding rate RR (μm / min) Roughness of copper sheet after grinding (nm) Porous Epoxy Disc 6.2 26 Resin copper ...

Embodiment 3

[0039] Mix 4000g phenolic resin powder, 400g epoxy resin powder, 300g curing agent hexamethylenetetramine, 200g glass hollow microspheres and 50g glass fiber powder evenly, pour it into a metal mold with a diameter of 610mm, and heat it with a press forming. The pressure is 20Mpa, the heating temperature is 180°C, and the heating and pressure curing is performed for 2 hours to form a porous mixed resin disc.

[0040] The obtained porous mixed resin disk had a Shore hardness of 90 D, and the proportion of pores was 5%.

[0041] The stainless steel sheet was ground by the porous mixed resin disc, and compared with the traditional resin iron disc. The test of the grinding rate uses a plane grinder SK-610Y with a pressure of 300g / cm 2 , the speed is 60rpm. The grinding liquid adopts single crystal diamond grinding liquid with a particle size D50 of 3 μm.

[0042] Grinding Disc Type Grinding rate RR (μm / min) Roughness of copper sheet after grinding (nm) Porou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com