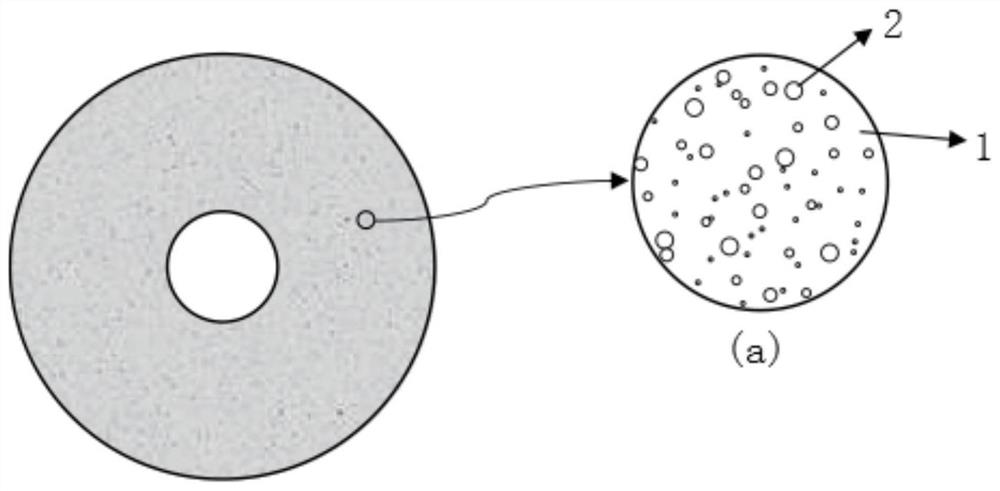

Porous resin grinding disc and preparation method thereof

A porous resin and grinding disc technology, which is applied in grinding tools, grinding/polishing equipment, abrasives, etc., can solve the problems of high cost, high requirements for use and maintenance, and large loss of grinding discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 20g of water (water as a pore-forming agent) and 100g of white carbon black to 1800g of polyurethane resin white material (polyether 303), add 200g of curing agent MOCA (3,3'-dichloro-4,4'-bis Aminodiphenylmethane), fully stirred evenly with a high-speed mixer, then added 2100g of polyurethane resin black material (PAPI), fully stirred evenly with a high-speed mixer, then poured the mixture into a stainless steel mold with a diameter of 610mm, and rapidly cured at room temperature to obtain Porous polyurethane resin disc.

[0027] The obtained porous polyurethane resin disk had a Shore hardness of 70D and a proportion of pores of 15%.

[0028] A 2-inch sapphire wafer was lapped using this porous polyurethane resin disc, compared to a conventional resin-copper disc. The test of the grinding rate adopts the surface grinder SK-610Y, the pressure is 300g / cm 2 , speed 60rpm. The grinding fluid is polycrystalline diamond grinding fluid with particle size D50 of 6 μm. ...

Embodiment 2

[0033] Add 200g of polymer hollow microspheres and 200g of cerium oxide micropowder into 3600g of epoxy resin, stir well with a high-speed mixer, then add 500g of epoxy resin curing agent T31, stir well with a high-speed mixer, pour the mixed slurry Put it into a stainless steel mold with a diameter of 610mm, and cure it at 60°C for 24 hours to form a porous epoxy resin disk.

[0034] The Shore hardness of the obtained porous epoxy resin disk was 60D, and the proportion of pores was 60%.

[0035] The copper sheet was ground with the porous epoxy resin disc, and compared with the traditional resin copper disc. The test of the grinding rate adopts the surface grinder SK-610Y, the pressure is 200g / cm 2 , speed 60rpm. The grinding fluid is a single crystal diamond grinding fluid with a particle size D50 of 5 μm.

[0036] Grinding Disc Type Grinding rate RR(μm / min) Copper roughness after grinding (nm) Porous Epoxy Disc 6.2 26 Resin copper plate 6.0 32...

Embodiment 3

[0039] Mix 4000g of phenolic resin powder, 400g of epoxy resin powder, 300g of curing agent hexamethylenetetramine, 200g of glass hollow microspheres and 50g of glass fiber powder, pour it into a metal mold with a diameter of 610mm, and heat it with a press forming. The pressure is 20Mpa, the heating temperature is 180°C, and the heat and pressure are cured for 2 hours to form a porous mixed resin disk.

[0040] The obtained porous mixed resin disk had a Shore hardness of 90D and a proportion of pores of 5%.

[0041] The stainless steel sheet is ground using the porous mixed resin disc, and compared with the traditional resin iron disc. The test of the grinding rate adopts the surface grinder SK-610Y, the pressure is 300g / cm 2 , speed 60rpm. The grinding fluid is a single crystal diamond grinding fluid with a particle size D50 of 3 μm.

[0042] Grinding Disc Type Grinding rate RR(μm / min) Copper roughness after grinding (nm) Porous Mixed Resin Tray 2.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com