Production method of hard polyimide foam material

A polyimide and foam material technology, applied in the field of plastic foaming, can solve the problems of complex foaming process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of production method of rigid polyimide foam material, comprises the steps:

[0040] (1) Preparation of polyamic acid precursor powder: adding binary anhydride and diamine to a polar solvent and stirring to obtain a polyamic acid precursor solvent, and drying by heating to obtain a polyamic acid precursor powder;

[0041] (2) Preparation of polyamide resin precursor powder: add dibasic anhydride and fatty alcohol into polar solvent and stir, then add isocyanate and stir to obtain polyamide resin precursor solution, heat and dry to obtain polyamide Lipid precursor powder;

[0042] (3) Preparation of foaming precursor: the polyamic acid precursor powder of step (1) and the polyamide resin precursor powder of step (2) are stirred, add a foam stabilizer and a foaming agent and stir to obtain foaming Precursor;

[0043] (4) Molding and foaming molding: adding the foaming precursor to the mold, and placing the mold in a microwave oven for molding and foaming;

[004...

Embodiment 2

[0060] The difference from Example 1 is that in step (1), the number of parts of the dibasic anhydride, diamine, and polar solvent is 3, 2, and 5, and other conditions remain unchanged.

Embodiment 3

[0062] The difference from Example 1 is that in steps (1) and (2), the heating and drying process is as follows: the solvent is put into a vacuum drying oven, the vacuum is -0.2MPa, the temperature is 150°C, and the time is 5h . , other conditions remain unchanged.

PUM

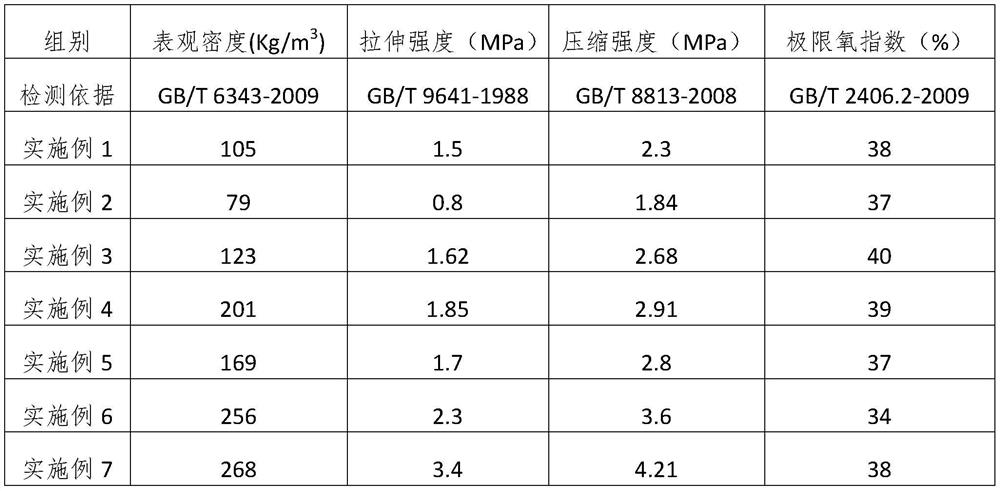

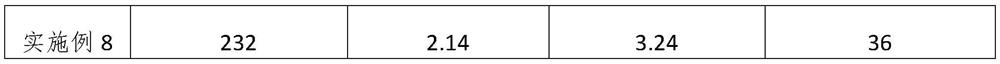

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com