A kind of titanium oxygen cluster -based solid -state polymer electrolyte and its preparation methods and applications

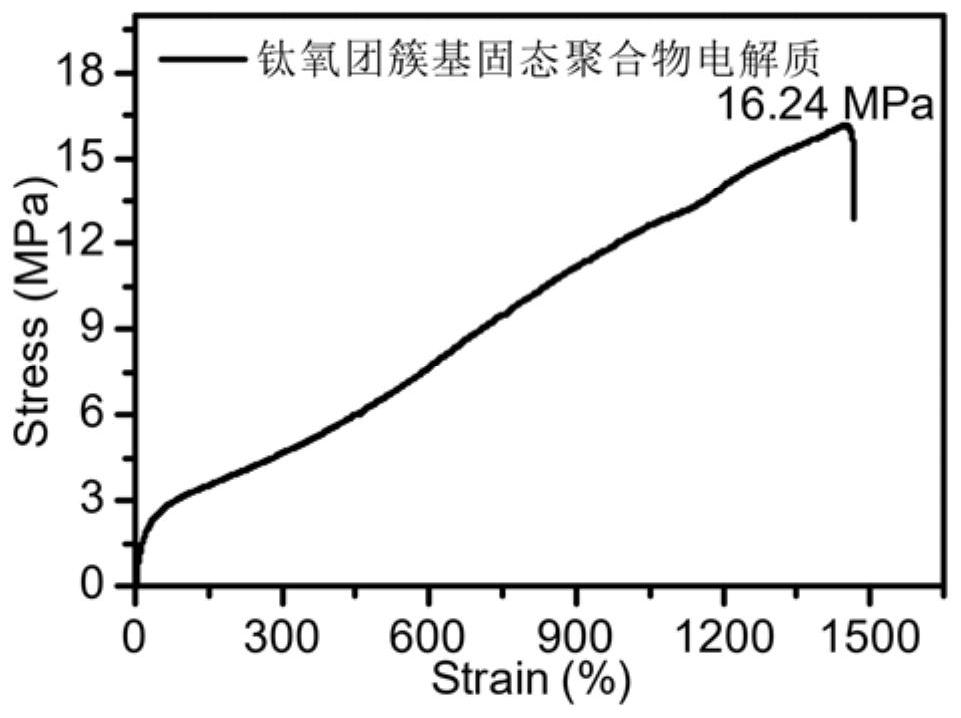

A technology of solid polymers and electrolytes, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as hindering electrolyte ion conductivity and weak interaction, so as to inhibit the growth of lithium dendrites and prolong cycle life , to overcome the effect of low ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) First weigh 1G m n = 2000G mol -1 The polytetrahydrofuran is dispersed in 1 mL N, N-dimethylformamide, and 168 μl of hexamethylene diisocyanate and 15 μl of Dikutanikhalate, stirred at 30 ° C for 2 hours to obtain a uniform and transparent solution.

[0036] 2) Will 50mg Ti 32 (μ) 2 -O) 8 (μ) 3 -O) 8 (OCH) 2 CH 2 O) 32 (RCOO) 16 (OCH) 2 CH 2 OH) 16 (R = ethyl) was dispersed in 1 ml n, N-dimethylformamide, and the reaction liquid obtained from step 1) was added, and the reaction was stirred at 30 ° C for 5 h to obtain a uniformly transparent solution, that is, a polymeric matrix solution.

[0037] 3) According to the EO: Li molar ratio of 16: 1, double trifluoromethylsulfonimide, add 10 wt.% Plasticic carbonate, dispersed at 2 ml N, N-dimethylformamide. The mixed solution was added to step 2), and the reaction mixture was stirred at 30 ° C to obtain a uniform and transparent solution at 30 ° C.

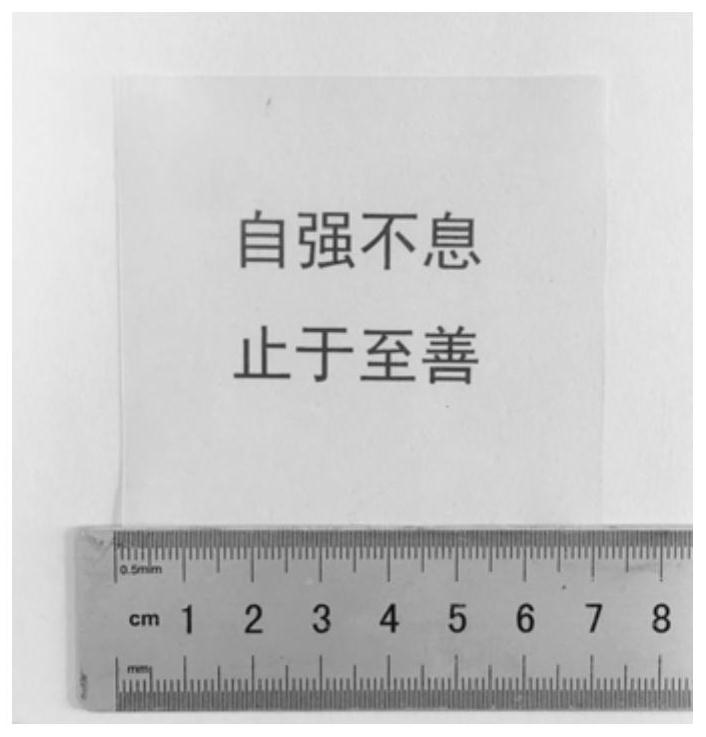

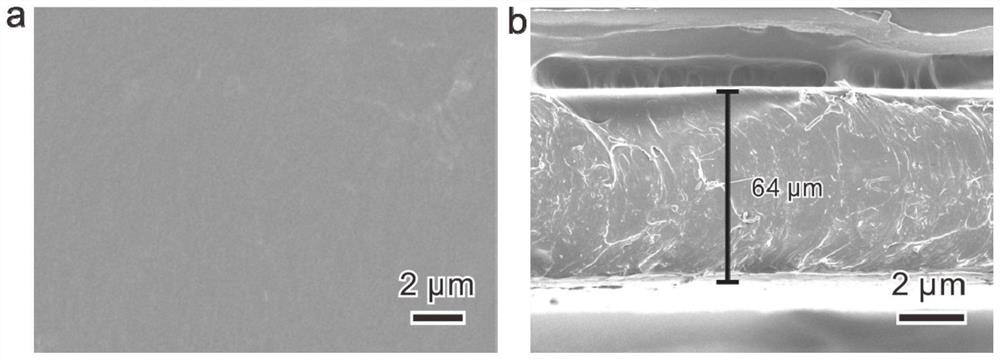

[0038] 4) The solution obtained by step 3) was scraped in the polytetrafluoroe...

Embodiment 2

[0041] 1) First weigh 1G m n = 2000G mol -1 The polyethylene glycol was dispersed in 10 mL of dichloromethane, and 100 μl of hexamethylene diisocyanate was added and 5 μl of dibutyltin, and the reaction was stirred at 30 ° C for 5 hours to obtain a uniform and transparent solution.

[0042] 2) Ten mg Ti 6 O 6 (OCH) 3 ) 6 (AB) 6 In 1 ml of dichloromethane, it was added to the reaction liquid obtained from step 1), and the reaction was stirred at 30 ° C for 10 h to obtain a uniform and transparent solution, that is, a polymer matrix solution.

[0043] 3) According to the EO: Li molar ratio of 12: 1, the double trifluoromethylsulfonimide, dispersed in a mixed solution of 5 ml of acetonitrile and dichloromethane, wherein the volume ratio of acetonitrile and dichloromethane is 1: 1. , The reaction liquid obtained by adding to step 2), the reaction is stirred at 30 ° C for a uniform and transparent solution.

[0044] 4) The solution obtained from step 3) was scraped in the polytetrafluo...

Embodiment 3

[0046] 1) First weigh 2G m n = 4000g Mol -1 The polyethylene glycol was dispersed in 0.5 ml of dimethylacetamide, and 202 μl of lysine diisocyanate and 30 μl of dibutyltin, stirred at 30 ° C for 1 h to obtain a uniform and transparent solution.

[0047] 2) Put 100 mg Ti 4 O 2 (O i Bu) 10 (ABZ) 2 In 1 ml of dimethylacetamide, it was added to the reaction liquid obtained from step 1), and the reaction was stirred at 30 ° C to obtain a uniform and transparent solution, ie the polymer matrix solution.

[0048] 3) According to the EO: Li molar ratio of 20: 1, lithium boric acid acid acid, add 20 wt.% Plasticic acid carbonate, dispersed in a mixed solution of 2 ml acetonitrile and dimethylacetamide, wherein acetonitrile and acetonitrile The volume ratio of the based on the acetamide was 1: 1, added to step 2), and the reaction was stirred at 30 ° C for 5 hours to obtain a uniform and transparent solution.

[0049] 4) The solution obtained by step 3) is scraped in the polytetrafluoride m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com