Preparation method of molecular imprinting solid phase extraction film with triphenylmethane molecule replacing malachite green, and application

A solid-phase extraction membrane and triphenylmethane technology, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as high price of template molecules, leakage of template molecules, and small extraction capacity , to achieve the effect of stable physical and chemical properties, short equilibration time and large extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

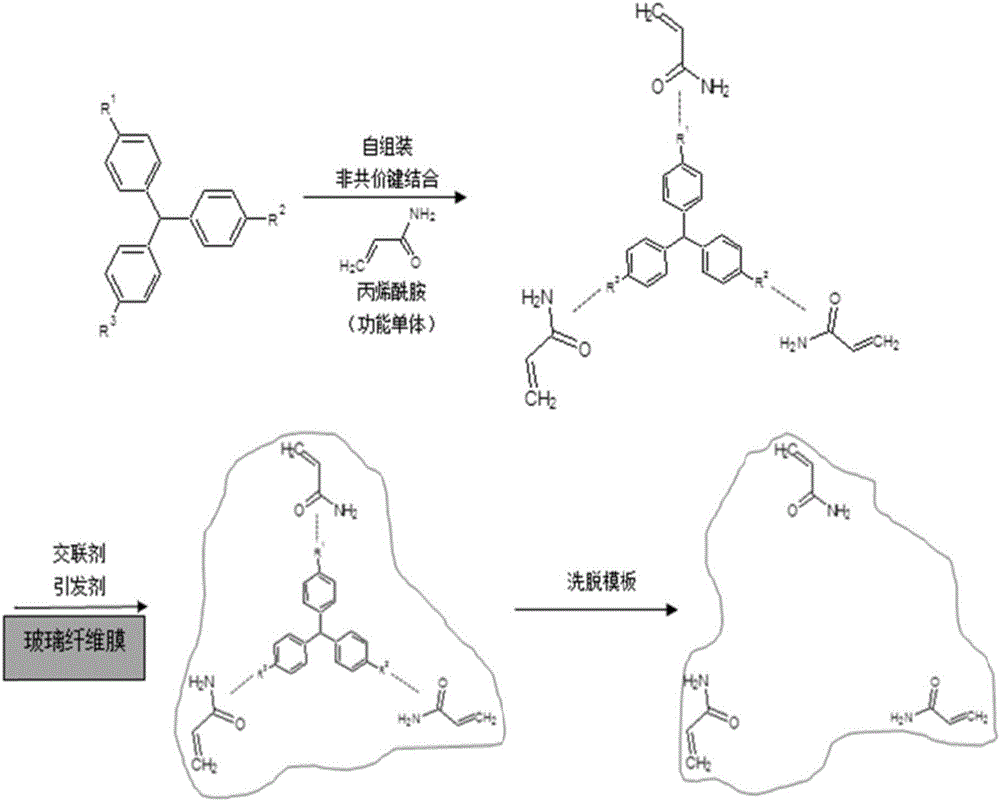

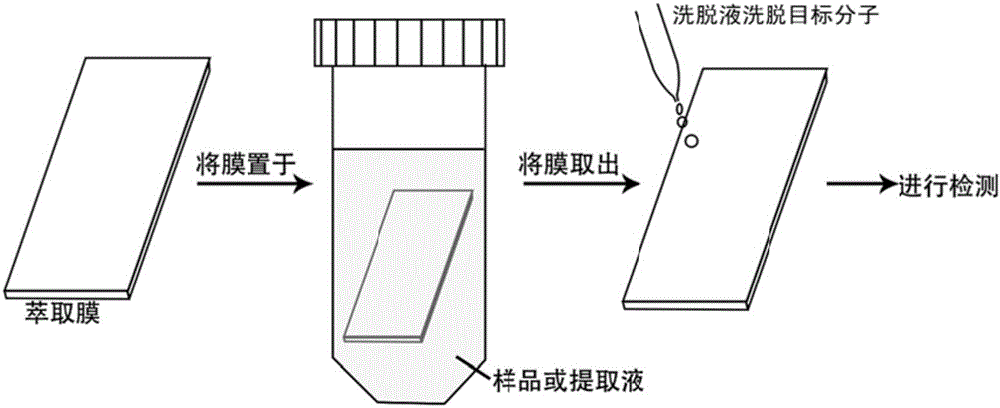

[0037] Example 1: Preparation and Application of Molecularly Imprinted Solid-Phase Extraction Membrane (MIP)

[0038] S01: Prepare a mixed organic solution containing triphenylmethane, 4-vinylbenzoic acid, crosslinking agent ethylene glycol dimethacrylate, and azo initiator azobisisobutyronitrile: mix 1mol of triphenylmethane, 4- 2 mol of vinyl benzoic acid, 6 mol of ethylene glycol dimethacrylate as a crosslinking agent, an appropriate amount of toluene as an organic solvent, and 6 mol of azo initiator azobisisobutyronitrile were subjected to ultrasonic miscibility treatment for 30 minutes to obtain a mixed solution;

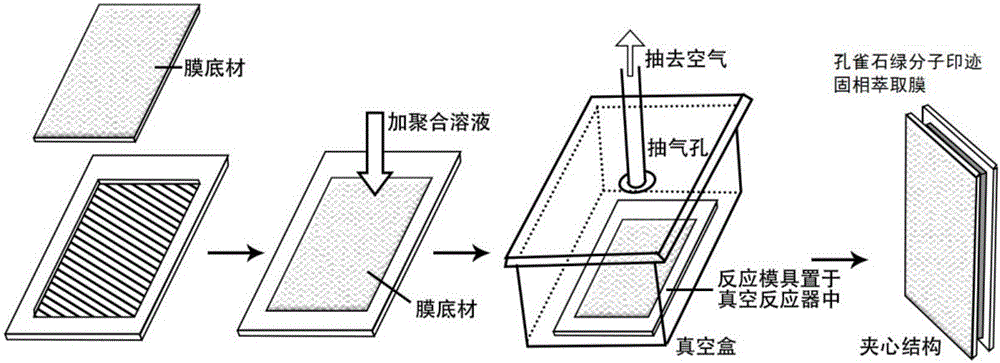

[0039] S02: Put the mixed organic solution in a refrigerator at 4°C for 6 hours for prepolymerization, take out the mixed organic solution after the prepolymerization is completed, and pour nitrogen gas into it for several minutes, then pour the mixed organic solution into a reaction mold, At the same time, glass fiber membranes matching the size of the mold ar...

Embodiment 2

[0042] Example 2 Preparation and Application of Molecularly Imprinted Solid-Phase Extraction Membrane (MIP)

[0043] S01: Prepare a mixed organic solution containing triphenylmethane, trifluoromethacrylic acid, crosslinking agent divinylbenzene, and azo initiator azobisisoheptanonitrile: mix 1 mol of triphenylmethane, 3 mol of trifluoromethacrylic acid, 12 mol of the crosslinking agent divinylbenzene, an appropriate amount of organic solvent chloroform, and 7 mol of the azo initiator azobisisoheptanonitrile were subjected to ultrasonic miscibility treatment for 30 minutes to obtain a mixed solution;

[0044] S02: Put the mixed organic solution in a refrigerator at 4°C for 6 hours for prepolymerization, take out the mixed organic solution after the prepolymerization is completed, and pour nitrogen gas into it for several minutes, then pour the mixed organic solution into a reaction mold, At the same time, glass fiber membranes matching the size of the mold are added, and polyme...

Embodiment 3

[0047] Example 3 Preparation and Application of Molecularly Imprinted Solid-Phase Extraction Membrane (MIP)

[0048] S01: Prepare a mixed organic solution containing phenolphthalein, acrylamide, cross-linking agent ethylene glycol dimethacrylate, azo initiator dimethyl azobisisobutyrate: mix 1 mol of phenolphthalein, 3 mol of acrylamide, cross-linking agent 12 mol of ethylene glycol dimethacrylate, an appropriate amount of acetonitrile as an organic solvent, and 7 mol of azo initiator dimethyl azobisisobutyrate were subjected to ultrasonic miscibility treatment for 30 minutes to obtain a mixed solution;

[0049] S02: Put the mixed organic solution in a refrigerator at 4°C for 6 hours for prepolymerization, take out the mixed organic solution after the prepolymerization is completed, and pour nitrogen gas into it for several minutes, then pour the mixed organic solution into a reaction mold, At the same time, glass fiber membranes matching the size of the mold are added, and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com