Preparation method of non-vacuum downward-casting copper-zirconium alloy slab ingot

A copper-zirconium alloy, non-vacuum technology, applied in the field of alloy manufacturing, can solve the problems of unmet requirements, high production cost, uneven distribution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

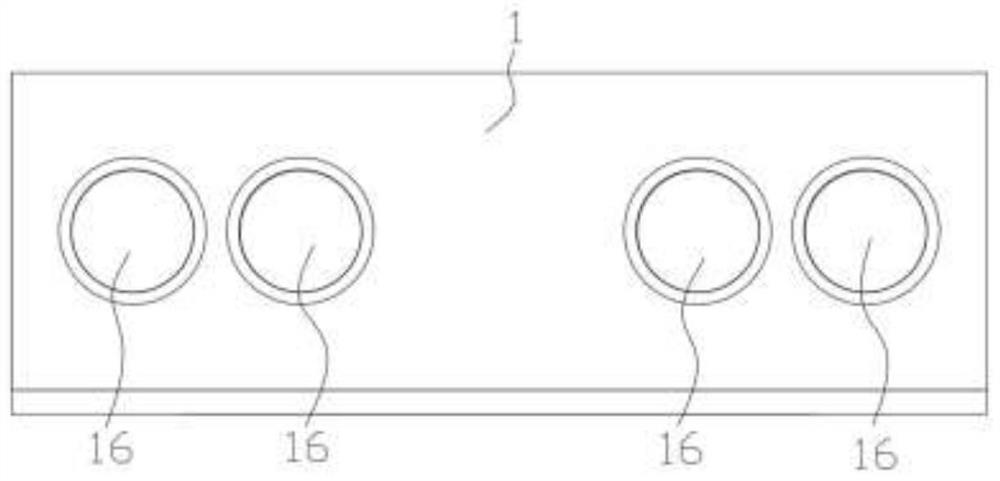

Image

Examples

Embodiment 1

[0059] A method for preparing copper-zirconium alloy slabs under non-vacuum, including the following steps:

[0060] S1 ingredients: according to the percentage content, weigh the required raw materials, select 99% electrolytic copper plate, 0.7% copper-zirconium alloy, rare earth Re0.1%, copper-magnesium alloy 0.2%, titanium 0.01%, electrolytic copper plate, copper-zirconium alloy, Rare earth Re, copper-magnesium alloys and titanium are reserved for use. Among them, the zirconium content in the copper-zirconium alloy is 35-55%, and the magnesium content in the copper-magnesium alloy is 10-20%;

[0061] S2 smelting:

[0062] 1) Put the electrolytic copper plate into the crucible of the medium frequency induction furnace, add the power and other copper plates to melt, add the covering agent, the use amount of the covering agent is 0.45%wt of the electrolytic copper plate weight, which is 53% of glass by mass percentage, fluorinated Calcium 22%, sodium fluoride 25%;

[0063] 2) The tem...

Embodiment 2

[0073] This embodiment is basically the same as embodiment 1, and the difference is that the amount and ratio of the covering agent used in the smelting step S2 are different.

[0074] The use amount of the covering agent is 0.35% wt of the weight of the electrolytic copper plate, and it is composed of 60% glass, 20% calcium fluoride and 20% sodium fluoride in terms of mass percentage.

Embodiment 3

[0076] This embodiment is basically the same as embodiment 1, and the difference is that the amount and proportion of covering agent used in the smelting step S2 are different.

[0077] The use amount of the covering agent is 0.60%wt of the weight of the electrolytic copper plate, which is composed of 50% glass, 20% calcium fluoride, and 30% sodium fluoride in terms of mass percentage content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com