Binder as well as preparation method and application thereof

A technology of binder and dispersant, which is applied in the field of binder and its preparation, can solve problems such as injection defects, difficulty in automatic production, and low strength of sintered billets, so as to avoid rearrangement and agglomeration, facilitate automatic production, and feed material surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The following components were weighed in parts by weight: 7 parts of microcrystalline wax, 40 parts of 1# polyacrylic resin, 30 parts of 2# polyacrylic resin, 20 parts of PS: 1.5 parts of DOP, and 1.5 parts of dispersant.

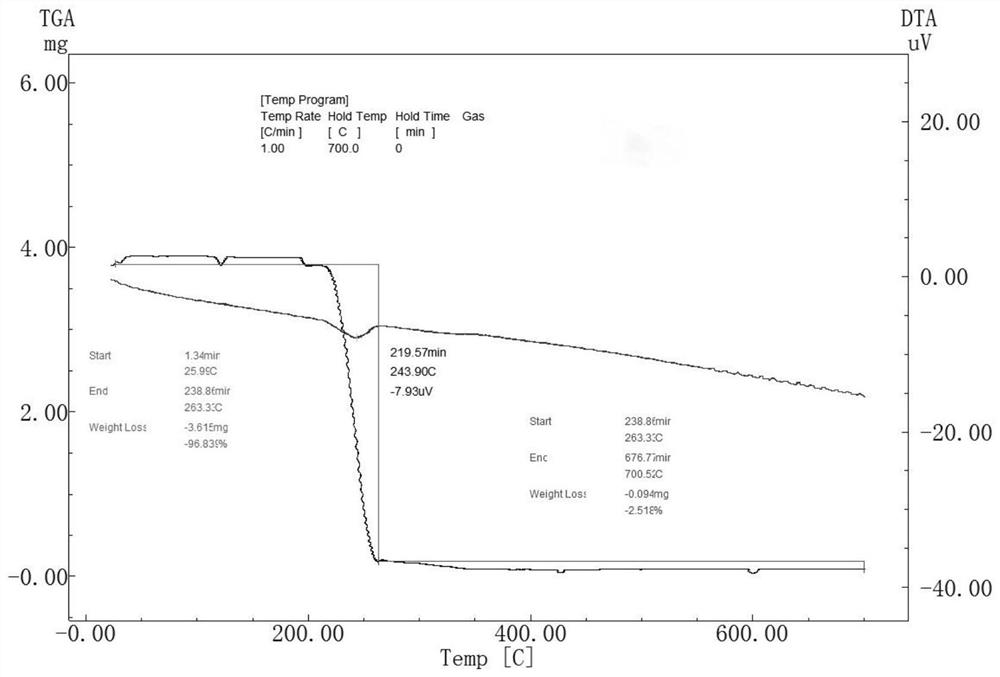

[0041]The 1# polyacrylic resin is a polyacrylic resin with a molecular weight of 120,000 and a Tg of 110°C, and its thermal decomposition temperature is 235°C; the 2# polyacrylic resin is a polyacrylic resin with a molecular weight of 40,000 and a Tg of 35°C. The decomposition temperature is 280°C, the decomposition temperature of the PS is 320°C, and the dispersant is an anionic polyacrylic dispersant.

[0042] Put the weighed material into a double-helix high-temperature mixer, stir and mix at a temperature of 120°C for 4 hours, and the stirring rate is 1000 rpm. The binder is poured into a ceramic crusher, crushed into particles with a diameter of 1mm, and packaged for storage.

Embodiment 2

[0044] The following components were weighed in parts by weight: 10 parts of microcrystalline wax, 45 parts of 1# polyacrylic resin, 35 parts of PS, 5 parts of EVA, 1.5 parts of DOP, and 3.5 parts of dispersant.

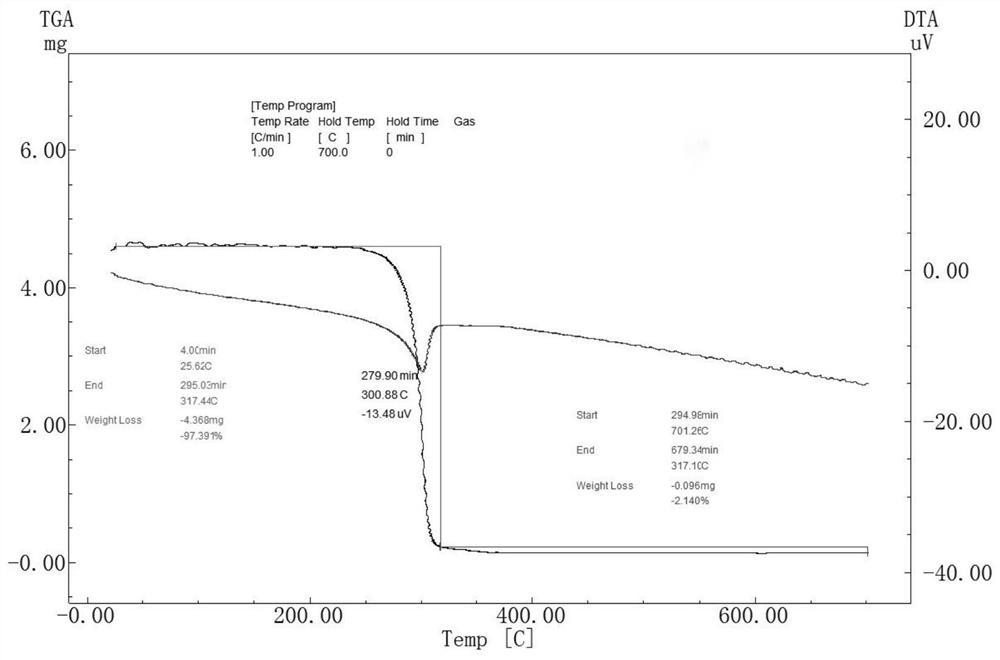

[0045] The 1# polyacrylic resin is a polyacrylic resin with a molecular weight of 200,000, a Tg of 65°C, and a thermal decomposition temperature of 245°C; the decomposition temperature of the PS is 325°C, and the decomposition temperature of the EVA is 420°C. The dispersant is an anionic polyacrylic dispersant.

[0046] Put the weighed material into a double-helix high-temperature mixer, stir and mix at a temperature of 140 ° C for 3 hours, and the stirring speed is 900 rpm. The binder is poured into a ceramic crusher, crushed into particles with a diameter of 2mm, and packaged for storage.

Embodiment 3

[0048] The following components were weighed in parts by weight: 5 parts of microcrystalline wax, 47 parts of 1# polyacrylic resin, 35 parts of PS, 7 parts of EVA, 2.5 parts of DOP, and 3.5 parts of dispersant.

[0049] The 1# polyacrylic resin is a polyacrylic resin with a molecular weight of 400,000, a Tg of 105°C, and a thermal decomposition temperature of 210°C; the decomposition temperature of the PS is 325°C, and the decomposition temperature of the EVA is 420°C. The dispersant is an anionic polyacrylic dispersant.

[0050] Put the weighed material into a double-helix high-temperature mixer, stir and mix at a temperature of 160°C for 2 hours, and the stirring speed is 800 rpm. The binder is poured into a ceramic crusher, crushed into particles with a diameter of 3mm, and packaged for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com