Method for manufacturing indium ball array of small-center-distance focal plane detector

A technology of focal plane detector and center distance, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of small size, uneven indium column, etc., and achieve improved connectivity and high equipment compatibility , Improve the effect of tolerance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

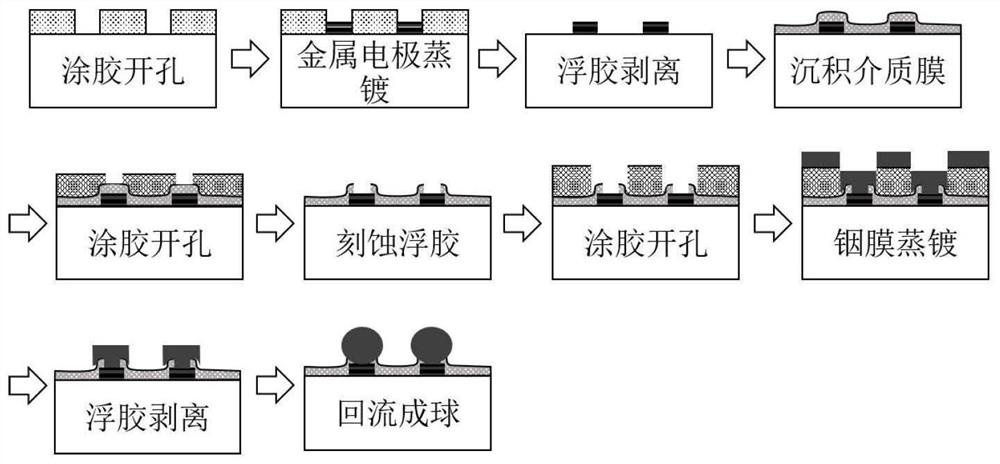

[0029]The purpose of this embodiment is to use the manufacturing method of the high-uniformity indium ball array disclosed in the present invention to produce a satisfying and readout circuit for an InAs / GaSb type II superlattice mid-wave infrared focal plane photosensitive chip with a center distance of 15 microns. The high-uniformity indium ball array required by flip-bonding verifies the feasibility of the present invention.

[0030] Based on the InAs / GaSb type II superlattice focal plane photosensitive chip after the p-contact electrode is prepared, the following steps are carried out:

[0031] (1) Using AZ4330 positive photoresist, through ultraviolet exposure and development, a square contact electrode hole pattern is produced in the center of the pixel. The sides of the holes are 7 microns long.

[0032] (2) Ion beam sputtering coating equipment is used to vapor-deposit three metal layers of chromium, nickel, and gold in sequence, with thicknesses of 100, 600, and 100 ...

Embodiment 2

[0043] The purpose of this embodiment is to produce an InGaAs / InAsP / InP short-wave infrared focal plane photosensitive chip with a center distance of 12.5 microns, using the manufacturing method of the high-uniformity indium ball array disclosed in the present invention, to produce a chip that meets the requirements of flip-bonding with the readout circuit. The high-uniformity indium ball array verifies the feasibility of the present invention.

[0044] Based on the nGaAs / InAsP / InP focal plane photosensitive chip after the p-contact electrode is prepared, the following steps are carried out:

[0045] (1) Using AZ4330 positive photoresist, through ultraviolet exposure and development, a square contact electrode hole pattern is produced in the center of the pixel. The sides of the holes are 6 microns long.

[0046] (2) Ion beam sputtering coating equipment is used to vapor-deposit three metal layers of chromium, nickel, and gold in sequence, with thicknesses of 50, 400, and 70 ...

Embodiment 3

[0057] The purpose of this embodiment is to use the manufacturing method of the high-uniformity indium ball array disclosed in the present invention for an InGaAs / InP short-wave infrared focal plane photosensitive chip with a center distance of 10 microns to produce a high-uniformity indium ball array that meets the requirements of flip-soldering with the readout circuit. permanent indium ball array to verify the feasibility of the present invention.

[0058] Based on the InGaAs / InP focal plane photosensitive chip after the p-contact electrode is prepared, the following steps are carried out:

[0059] (1) Using AZ4330 positive photoresist, through ultraviolet exposure and development, a square contact electrode hole pattern is produced in the center of the pixel. The side length of the hole is 5.5 microns.

[0060] (2) Ion beam sputtering coating equipment is used to vapor-deposit three metal layers of chromium, nickel, and gold in sequence, with thicknesses of 20, 200, and 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com