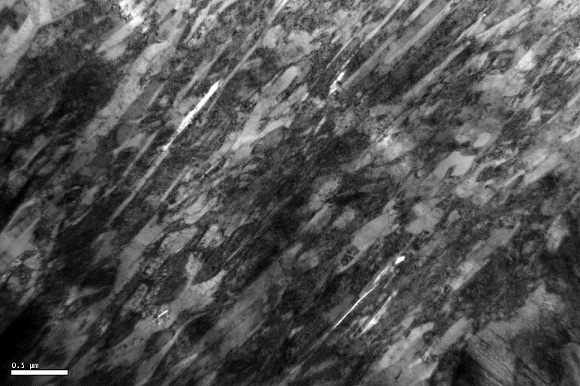

A kind of high-strength steel with nano, layered and metastable skeletal tissue and its preparation method

A high-strength steel and nano-technology, applied in layered and metastable structures, the microstructure is in the nano-scale field, to achieve the effect of increasing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing high-strength steel with nano, layered and metastable skeletal tissue, comprising the following steps;

[0023] 1), weigh the alloy composition, weigh 0.04wt.% of C, 7.0wt.% of Mn, 2.0wt.% of Cu, 3.0wt.% of Ni, 1.5wt.% of Al according to the weight percentage of the alloy composition, The balance is Fe;

[0024] 2), vacuum smelting and casting the alloy components weighed in step 1), and then forging at a temperature of 1050° C., with a forging ratio of 3.0, to obtain a forged billet with a thickness of 30 mm;

[0025] 3) Heat a 30mm thick forging billet at 1200°C for 2.0h, then hot-roll it at 1150°C, with a total reduction rate of 90%, to obtain a hot-rolled sheet with a thickness of 3.0mm, and then conduct cold rolling, with a reduction rate of 90%. 50% to obtain a cold-rolled sheet with a thickness of 1.5mm;

[0026] 4), heat treatment, the obtained cold-rolled plate with a thickness of 1.5mm is kept at 1050° C. for 15 minutes, water quenched...

Embodiment 2

[0030] A method for preparing high-strength steel with nano, layered and metastable skeletal tissue, comprising the following steps;

[0031] 1), weigh the alloy composition, weigh 0.01wt.% of C, 8.0wt.% of Mn, 1.5wt.% of Cu, 2.0wt.% of Ni, 1.0wt.% of Al according to the weight percentage of the alloy composition, The balance is Fe;

[0032] 2), vacuum smelting and casting the alloy components weighed in step 1), and then forging at a temperature of 1150° C., with a forging ratio of 1.5, to obtain a forged billet with a thickness of 50 mm;

[0033] 3) Heat a 50mm thick forging billet at 1250°C for 2.0h, then hot-roll it at 1100°C, the total reduction rate is 94%, to obtain a hot-rolled plate with a thickness of 3.0mm, and then perform cold rolling, the reduction rate 50% to obtain a cold-rolled sheet with a thickness of 1.5mm;

[0034] 4), heat treatment, the obtained cold-rolled plate with a thickness of 1.5mm is kept at 1100° C. for 20 minutes, water quenched to room tempe...

Embodiment 3

[0038] A method for preparing high-strength steel with nano, layered and metastable skeletal tissue, comprising the following steps;

[0039] 1), weigh the alloy composition, weigh 0.06wt.% of C, 9.0wt.% of Mn, 4wt.% of Cu, 1.0wt.% of Ni, 2wt.% of Al according to the weight percentage of the alloy composition, and the balance 2) vacuum smelting and casting the alloy components weighed in step 1), and then forging at a temperature of 1100° C., with a forging ratio of 2, to obtain a forged billet with a thickness of 50 mm;

[0040] 3) Heat a 50mm thick forging billet at 1220°C for 2.2h, then hot-roll it at 1130°C, the total reduction rate is 92%, to obtain a hot-rolled plate with a thickness of 4.0mm, and then perform cold rolling, the reduction rate 55% to obtain a cold-rolled sheet with a thickness of 1.8mm;

[0041] 4), heat treatment, the obtained cold-rolled plate with a thickness of 1.8mm is kept at 1020° C. for 25 minutes, water quenched to room temperature, then kept at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com