Composite comprising green rust and carbon for environmental remediation

A technology for environmental remediation and composites, applied in the field of composites and suspensions for environmental remediation, can solve the problems of low particle stability, high cost and limited efficiency, and achieve the effects of high mobility, simple manufacturing, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0183] Example 1: Experimental Setup for Testing Chlorinated Vinyl Solvent Remediation

[0184] Experiments were performed by analyzing the headspace above the reaction mixture of ethylene chloride exposed to the GR-bone char (BC) complex.

[0185] The vinyl chloride and dehalogenation products in the headspace were quantified using a GC chromatograph with a GC-MS system consisting of a ThermoTRACE GC 1300 gas chromatograph and a Triplus300HS headspace sampler coupled with a dual detector of EDC and FID. Use PoraBOND U column (25m×0.35mm×7μm), and use 1.2mL min -1 nitrogen as the carrier gas.

[0186] The oven temperature program is as follows: 40°C (2 minutes), 25°C min -1 to 220°C (2 minutes). The samples were incubated at 40 °C for 0.5 min, then 200 μL of gas sample was injected at a split ratio of 50 and injected at an injector and syringe temperature of 85 °C.

[0187] Set the ECD detector to 280 °C and the make-up gas flow to 15.0 mL min -1 . Set the ECD detector...

Embodiment 2

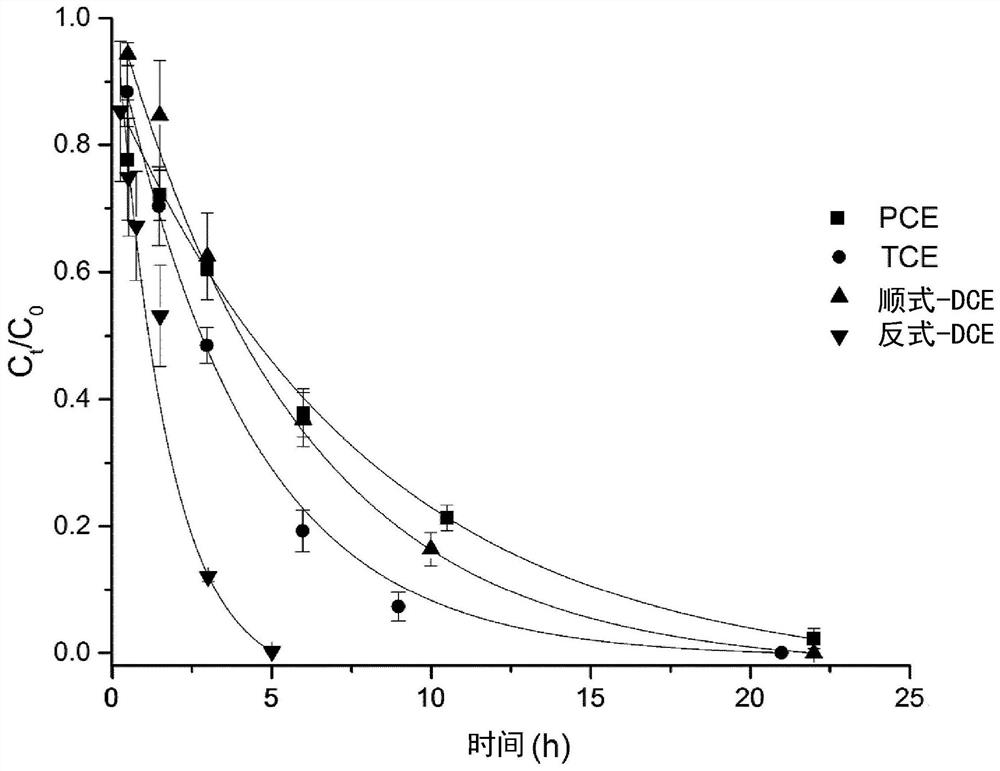

[0188] Example 2: GR-bone char complex for dehalogenation of vinyl chloride

[0189] The kinetics of the dehalogenation of different vinyl chlorides in solvent was examined upon contact and exposure to a complex according to the present disclosure comprising GR (patina) and bone char. The experimental setup was as described in Example 1.

[0190] Compound by Hybrid Patina GR Cl Made with Bone Charcoal (89440_FLUKA).

[0191] Can be by co-precipitating iron salts, by oxidizing iron(II) solutions at constant pH, by glycine-assisted methods or by oxidizing solid Fe(OH) 2 to synthesize GR compounds.

[0192] A mixture was prepared with 7.4 g / L GR Cl (corresponds to GR Cl 11 mM Fe(II)), 1 g / L bone char and vinyl chloride in an initial concentration of about 20 μM (0.1 μmol total in the headspace vial) and an initial pH of 8.0. Alternatively, a mixture was prepared with 3.2 g / L GR Cl (equivalent to GR Cl 22 mM Fe(II)). The mixture was shaken at 300 rpm at room temperature...

Embodiment 3

[0216] Example 3: GR-bone char composite with char pyrolyzed at different temperatures

[0217] Carbons produced at pyrolysis temperatures of 300 to 1050 °C were tested for TCE dehalogenation.

[0218] The same experimental setup as described in Examples 1 and 2 was used. The composites were prepared as described in Example 2, wherein the chars were biochar (corn BC400) produced by pyrolysis of corn stover at 400°C, and biochar (corn BC400) by bone meal at 300°C (BC300), 450°C (BC450), 600°C, respectively Bone char produced by pyrolysis at 1050°C (BC600), 750°C (BC750), 900°C (BC900) or 1050°C (BC1050).

[0219] Figure 4 The amount of residual TCE and acetylene formed after each headspace vial was contacted with the complex and reacted for 24 hours is shown. Note that up to 0.1 μmol of acetylene can be formed per vial.

[0220] It can be seen that the bone char produced at the higher pyrolysis temperature resulted in a faster TCE removal rate and more acetylene formatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com