Spring nanowire detector for cell mechanics detection and detection method thereof

A nanowire and detector technology, which is applied in the field of cell mechanics testing, can solve the problems of high preparation cost of atomic force microscope needle tip testing, inability to realize probe shape design, large cell damage, etc., and achieve excellent controllability of diameter and shape , good biocompatibility, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

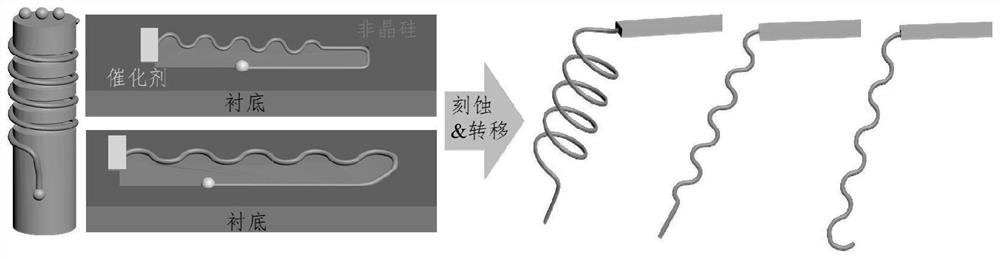

[0032] This embodiment provides a nanowire spring detector for cell membrane penetration detection and its preparation method, such as Figure 1-2 As shown, the specific steps include:

[0033] A. The silicon oxide wafer substrate material is cleaned, and the columnar guide steps are obtained by polystyrene ball-assisted Bosh process etching, and then placed in a plasma-enhanced chemical vapor deposition system, using low-melting indium as a catalyst, through Vertical 3D nanowire springs for growing nanowires at low temperature by planar solid-liquid-solid (IPSLS) growth mechanism. The diameter of the nanowire in this embodiment is 50 nanometers, the inner diameter of the spring is 1 micron, and the number of coils is 4.

[0034] B. Cut the end of the vertical three-dimensional nanowire spring on the substrate obtained in step A by photolithography and etching technology to obtain a nanowire structure with a straight end, and transfer it to a new substrate And carry out susp...

Embodiment 2

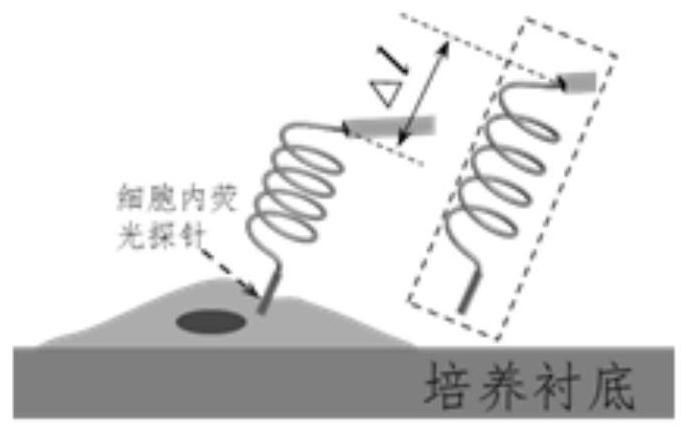

[0041] This embodiment provides a method for detecting the force required to penetrate the cell membrane with a calcium ion fluorescently labeled nanowire spring, such as figure 1 ,3 As shown, the specific steps include:

[0042] A. Clean the silicon oxide wafer substrate material, etch the wavy guide steps on the surface of the planar substrate, and then place it in a plasma-enhanced chemical vapor deposition system, using indium with a low melting point as a catalyst, through the planar solidification process. Growth of horizontal nanowire wavy linear springs at low temperature by liquid-solid (IPSLS) growth mechanism. The diameter of the nanowire is 80 nanometers, the inner diameter of the spring is 5 microns, and the number of coils is 5;

[0043] B. Cut off the end of the horizontal nanowire wavy linear spring on the substrate obtained in step A by photolithography and etching technology to obtain a nanowire structure with a straight end, and transfer it to a new substr...

Embodiment 3

[0047] This embodiment provides a method for hook-shaped nanowire springs to detect cell weight, such as figure 1 , 4 As shown, the specific steps include:

[0048] A. Clean the silicon oxide wafer substrate material, etch the wavy guide steps on the surface of the planar substrate, and then place it in a plasma-enhanced chemical vapor deposition system, using indium with a low melting point as a catalyst, through the planar solidification process. Growth of horizontal nanowire wavy linear springs at low temperature by liquid-solid (IPSLS) growth mechanism. The diameter of the nanowire is 60 nanometers, the inner diameter of the spring is 3 microns, and the number of coils is 5.

[0049] B. Cut off the end of the horizontal nanowire wavy linear spring on the substrate obtained in step A by photolithography and etching technology to obtain a hook-shaped nanowire structure and transfer it to a new substrate Overhanging and fixed.

[0050] C. Fix the hook-shaped nanowire spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com