Method and device for quickly separating oil and water under high temperature and high pressure

A high-temperature, high-pressure, oil-water technology, which is applied in the direction of the device whose axial direction can be reversed, the swirl device, etc., can solve the high local stress and deformation of the tangential rectangular inlet or the volute inlet, and the swirler cannot withstand relatively high pressure. High temperature and pressure loads cannot solve the problems of stress and deformation of structural components, so as to improve the flexibility of process operation, realize large-scale continuous operation, and improve the efficiency of oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] When the amount of oil is greater than the amount of water and the oil is dehydrated:

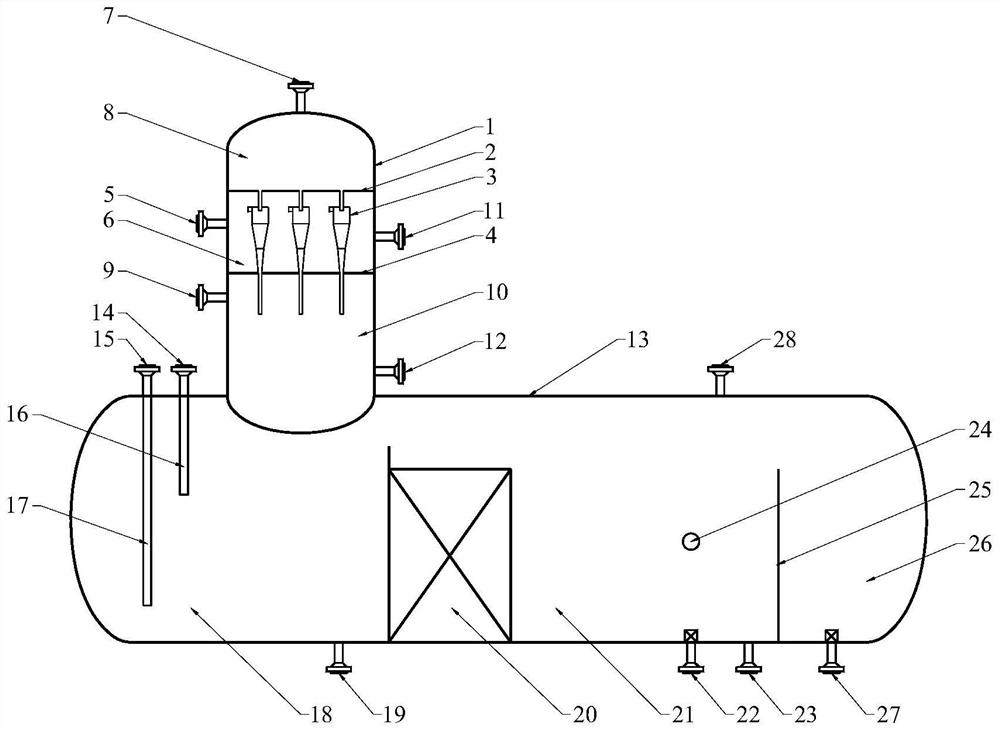

[0072] The device provided by the present invention includes an upper casing 1 and a lower casing 13. The upper casing 1 is equipped with a hydrocyclone 3 as a primary separation; the lower casing 13 is equipped with a coalescer 20 as a secondary separation. Therefore, the rapid separation of oil and water can be completed in one device.

[0073] The upstream oil-water mixture enters the feed area 6 composed of the upper shell 1, the upper partition 2, and the lower partition 4 through the mixed liquid inlet 5, and a hydrocyclone 3 is installed in the feed area 6 to adjust the split ratio of the cyclone 1 : 1 to 10, so that the overflow liquid meets the separation requirements, and the feed area 6 is provided with a sewage outlet 11 in the feed area, which can be regularly discharged.

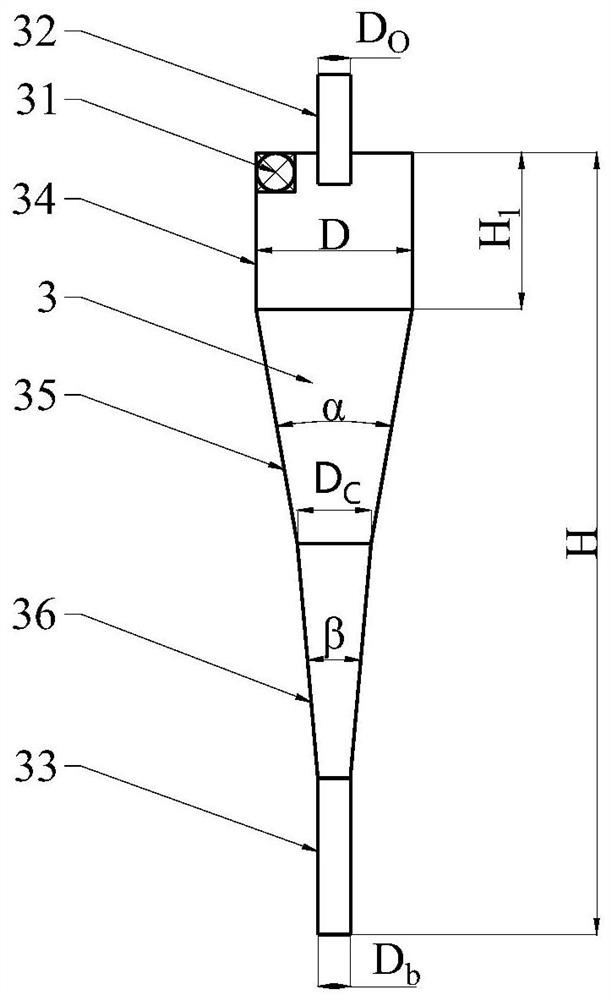

[0074] The mixed liquid in the feed zone 6 enters the feed pipe 31 of the hydrocyclone 3, and the...

Embodiment 2

[0077] When the amount of water is greater than the amount of oil, when performing water deoiling:

[0078] The device provided by the present invention includes an upper casing 1 and a lower casing 13. The upper casing 1 is equipped with a hydrocyclone 3 as a primary separation; the lower casing 13 is equipped with a coalescer 20 as a secondary separation. Therefore, the rapid separation of oil and water can be completed in one device.

[0079] The upstream oil-water mixture enters the feed area 6 composed of the upper shell 1, the upper partition 2, and the lower partition 4 through the mixed liquid inlet 5. The hydrocyclone 3 is installed in the feed area 6, and the hydrocyclone 3 is adjusted. The split ratio is 1:0.1~1, so that the underflow liquid meets the separation requirements, and the feed area 6 is provided with a sewage outlet 11 in the feed area, which can discharge sewage regularly.

[0080] The mixed liquid in the feed zone 6 enters the feed pipe 31 of the hydr...

Embodiment 3

[0083] When the quality of oil and water is the same:

[0084] The device provided by the present invention includes an upper casing 1 and a lower casing 13. The upper casing 1 is equipped with a hydrocyclone 3 as a primary separation; the lower casing 13 is equipped with a coalescer 20 as a secondary separation. Therefore, the rapid separation of oil and water can be completed in one device.

[0085] The upstream oil-water mixture enters the feed area 6 formed by the upper casing 1, the upper partition 2, and the lower partition 4 through the mixed liquid inlet 5, and a hydrocyclone 3 is installed in the feed area 6 to adjust the swirling flow. The split ratio of the device is 1:0.2~5, and the feed area 6 is provided with a sewage outlet 11 in the feed area, which can discharge sewage regularly.

[0086] The mixed liquid in the feed zone 6 enters the feed pipe 31 of the hydrocyclone 3, and the mixed liquid forms a high-speed rotating centrifugal motion in the cylindrical sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com