Organic solar cell taking PBDB-T: ITIC: alpha-In2Se3 as active layer and preparation method of organic solar cell

A PBDB-T, solar cell technology, applied in the field of solar cells, can solve problems such as complex processes, and achieve the effects of enhancing light absorption, improving photoelectric conversion efficiency, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

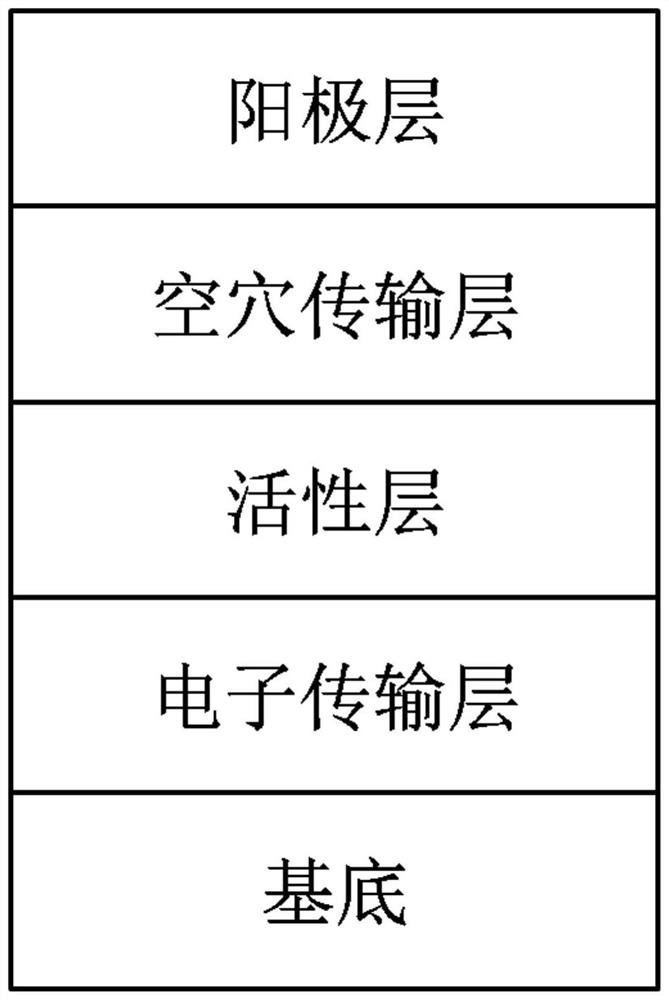

[0055] Using PBDB-T:ITIC:α-In in this embodiment 1 2 Se 3 The organic solar cell device structure as the active layer is: ITO / ZnO / PBDB-T:ITIC:α-In 2 Se 3 / MoO 3 / Ag.

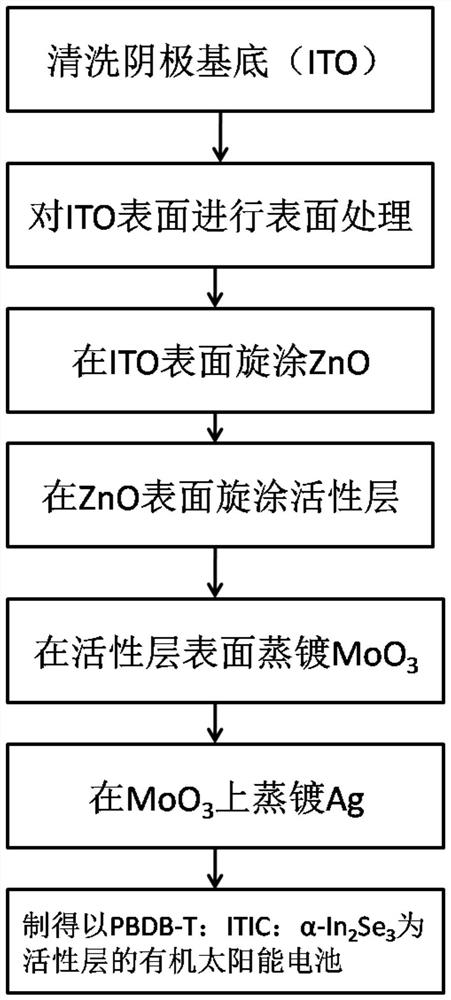

[0056] The above-mentioned PBDB-T:ITIC:α-In 2 Se 3 The preparation process of the organic solar cell that is the active layer is as follows:

[0057] Step 1. Use detergent, deionized water, acetone, absolute ethanol, and isopropanol to ultrasonically clean the cathode substrate for 20 minutes; then dry it in a vacuum oven at 80°C;

[0058] Step 2, carry out 14 minutes of plasma surface treatment on the surface of the cathode substrate (ITO) that has been cleaned and dried. This treatment method utilizes the strong oxidizing properties of ozone generated under microwaves to clean the residual organic matter on the ITO surface, etc., and simultaneously can make the ITO surface oxygen Increased vacancies improve the work function of the ITO surface;

[0059] Step 3. Spin-coat the ZnO solution on the surface...

Embodiment 2

[0068] Using PBDB-T:ITIC:α-In in this embodiment 2 2 Se 3 The organic solar cell device structure as the active layer is: ITO / ZnO / PBDB-T:ITIC:α-In 2 Se 3 / MoO 3 / Ag.

[0069] The above-mentioned PBDB-T:ITIC:α-In 2 Se 3 The preparation process of the organic solar cell that is the active layer is as follows:

[0070] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol for 15 minutes in sequence; then dry in a vacuum oven at 80°C;

[0071]Step 2, carry out 12 minutes of plasma surface treatment on the cathode base (ITO) surface of described cleaning and drying, this treatment method utilizes the strong oxidizing property that generates ozone under microwave to clean residual organic matter etc. on ITO surface, can make ITO surface oxygen simultaneously Increased vacancies improve the work function of the ITO surface;

[0072] Step 3. Spin-coat the ZnO solution on the surface of the ITO treated in step 2 at a speed of 40...

Embodiment 3

[0078] Using PBDB-T:ITIC:α-In in this embodiment 3 2 Se 3 The organic solar cell device structure as the active layer is: ITO / ZnO / PBDB-T:ITIC:α-In 2 Se 3 / MoO 3 / Ag.

[0079] The above-mentioned PBDB-T:ITIC:α-In 2 Se 3 The preparation process of the organic solar cell that is the active layer is as follows:

[0080] Step 1. Ultrasonic cleaning with detergent, deionized water, acetone, absolute ethanol, and isopropanol for 18 minutes in sequence; then dry in a vacuum oven at 80°C;

[0081] Step 2, carry out 13 minutes of plasma surface treatment on the cathode base (ITO) surface of described cleaning and drying, this treatment method utilizes the strong oxidizing property that generates ozone under microwave to clean residual organic matter etc. on ITO surface, can make ITO surface oxygen simultaneously Increased vacancies improve the work function of the ITO surface;

[0082] Step 3. Spin-coat ZnO solution on the ITO surface treated in step 2 at a speed of 4200 rpm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com