Antibacterial mask and preparation method thereof

A mask and antibacterial fiber technology, which is applied in biochemical fiber treatment, clothing, protective clothing, etc., can solve the problems of insufficient graphene dispersion and affect the antibacterial function of masks, and achieve high bactericidal effect, strong bactericidal performance, and good filtration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

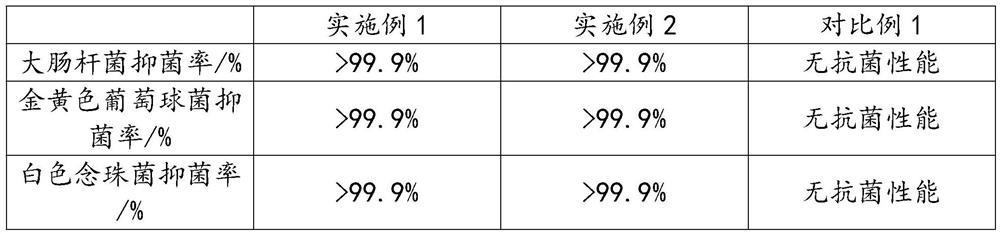

Embodiment 1

[0047] The antibacterial non-woven fabric is made of antibacterial fiber and bamboo charcoal fiber. After the antibacterial fiber and bamboo charcoal fiber are mixed according to the mass ratio of 10:3, they are opened by an opener, carded by a carding machine, and then thermally bonded and reinforced or watered. The thorns are reinforced into a uniform fiber layer to obtain antibacterial non-woven fabrics;

[0048] Wherein, the antibacterial fiber is prepared by the following method:

[0049] S1. Add dry cotton fibers and a certain amount of 4-bromobutyryl chloride to chloroform, heat, seal and stir at 48°C for 120 minutes, centrifuge, wash and dry after the reaction to obtain pretreated cotton fibers;

[0050] Wherein, the ratio of the amount of cotton fiber, 4-bromobutyryl chloride and chloroform is 10g: 2g: 35mL;

[0051] S2. Add the pretreated cotton fibers obtained in step S1 together with polyethyleneimine into an aqueous ethanol solution (the mass fraction of the aque...

Embodiment 2

[0056] The antibacterial non-woven fabric is made of antibacterial fiber and bamboo charcoal fiber. After the antibacterial fiber and bamboo charcoal fiber are mixed according to the mass ratio of 10:4, they are opened by an opener, carded by a carding machine, and then thermally bonded and reinforced or watered. The thorns are reinforced into a uniform fiber layer to obtain antibacterial non-woven fabrics;

[0057] Wherein, the antibacterial fiber is prepared by the following method:

[0058] S1. Add dry cotton fibers and a certain amount of 4-bromobutyryl chloride to chloroform, heat, seal and stir at 50°C for 110 minutes, centrifuge, wash and dry after the reaction to obtain pretreated cotton fibers;

[0059] Wherein, the ratio of the amount of cotton fiber, 4-bromobutyryl chloride and chloroform is 10g: 3g: 45mL;

[0060] S2. Add the pretreated cotton fibers obtained in step S1 together with polyethyleneimine into an aqueous ethanol solution (the mass fraction of the aque...

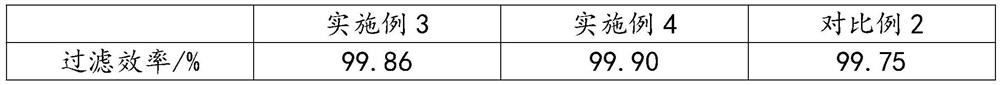

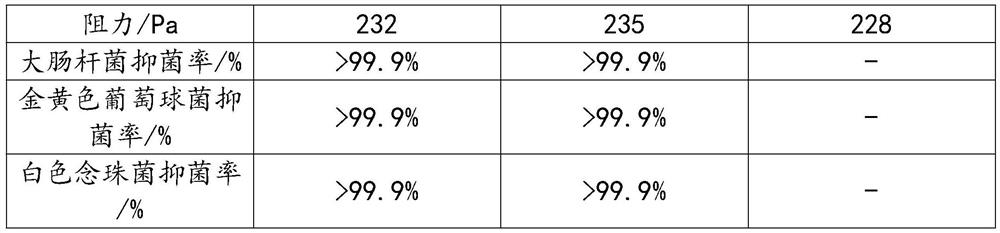

Embodiment 3

[0071] The middle layer is prepared by the following method:

[0072] 1) Under 200r / min mechanical stirring, dissolve 1g of benzoyl peroxide in 12mL of ethyl benzoate, and add it dropwise to the mixture of 45mL of water and 2g of emulsifier (sodium dodecylbenzenesulfonate) In the liquid, stir to form a complex emulsion;

[0073] 2) Add 3-propenyl-5,5-dimethyl-hydantoin into distilled water according to the solid-to-liquid ratio of 1g:26mL, stir until dissolved, then mix with the complex emulsion according to the volume ratio of 1:1, and stir evenly , to prepare the finishing solution;

[0074] 3) Finish the melt blown cloth with finishing liquid. The finishing process is double dipping and double rolling (150% liquid volume). After finishing, bake at 105°C for 2 minutes, then raise the temperature to 145°C and bake for 2 minutes, and rinse with water Wash 3 times, and finally bake at 105°C for 110 minutes, put it in a dryer to dry to constant weight, and obtain the middle me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com