Method for extracting squalene from crude shark liver oil

A technology for shark liver oil and squalene, which is applied in the field of oil processing, can solve the problems of high requirements on reaction systems and is not suitable for mass production, and achieves the effects of low equipment requirements, easy operation and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

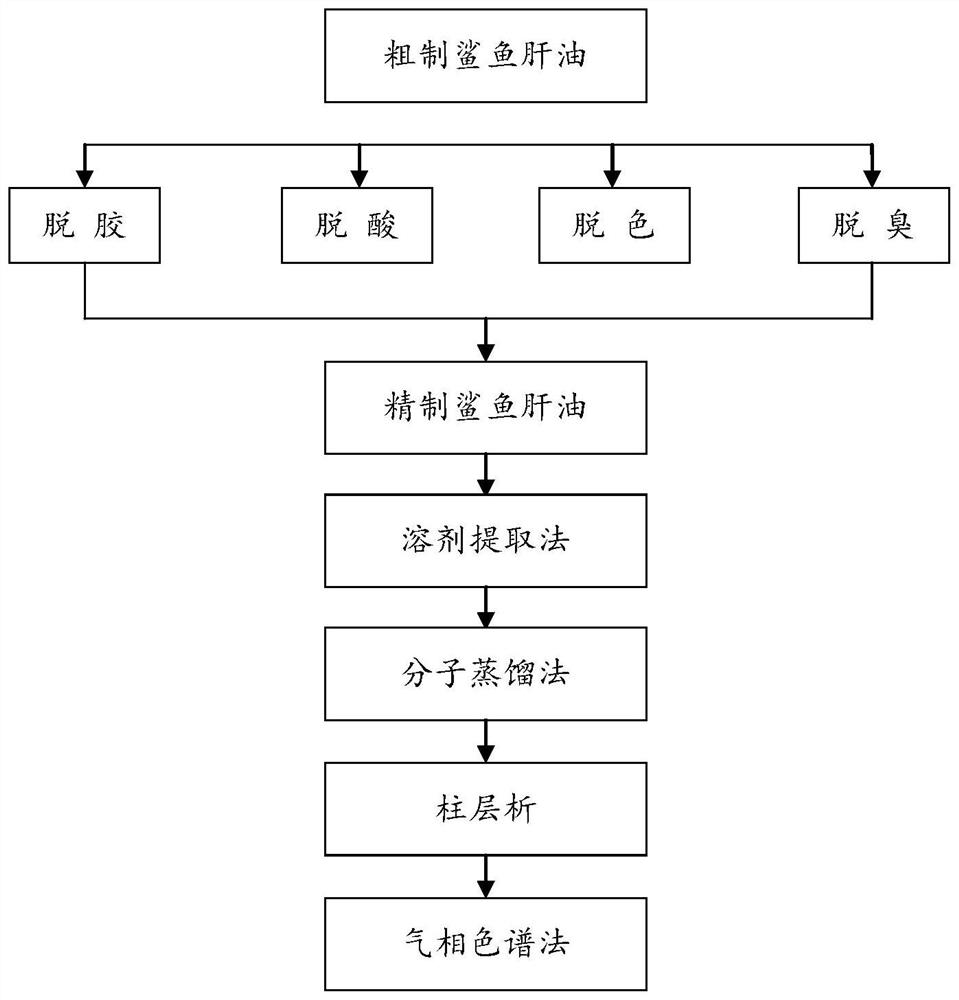

[0062] Embodiment 1, the method for preparing high-purity squalene from crude shark liver oil, carries out following steps successively:

[0063] 1) Refining crude shark liver oil:

[0064] Carry out degumming, deacidification, decolorization and deodorization respectively:

[0065] 1.1), degumming:

[0066] Add a degumming agent of 1% by weight of the crude shark liver oil to the crude shark liver oil, stir for 30 minutes at a temperature of 80° C. and a magnetic stirring speed of 500 rpm, and the degumming agent is an aqueous phosphoric acid solution with a volume concentration of 85%;

[0067] Then, centrifuge at 10 000g for 10 min; get degummed oil (shark liver oil after degumming);

[0068] 1.2), alkaline deacidification:

[0069] Add lye to the degummed oil, and stir for 20 minutes at a temperature of 40°C and a rotation speed of 500 rpm; the lye is an aqueous NaOH solution with a mass concentration of 20%;

[0070] The weight of lye W 总添加量 =W 理论值 +W 超量碱 ;W 理论值 =...

Embodiment 2

[0101] Embodiment 2, the method for preparing high purity from crude shark liver oil:

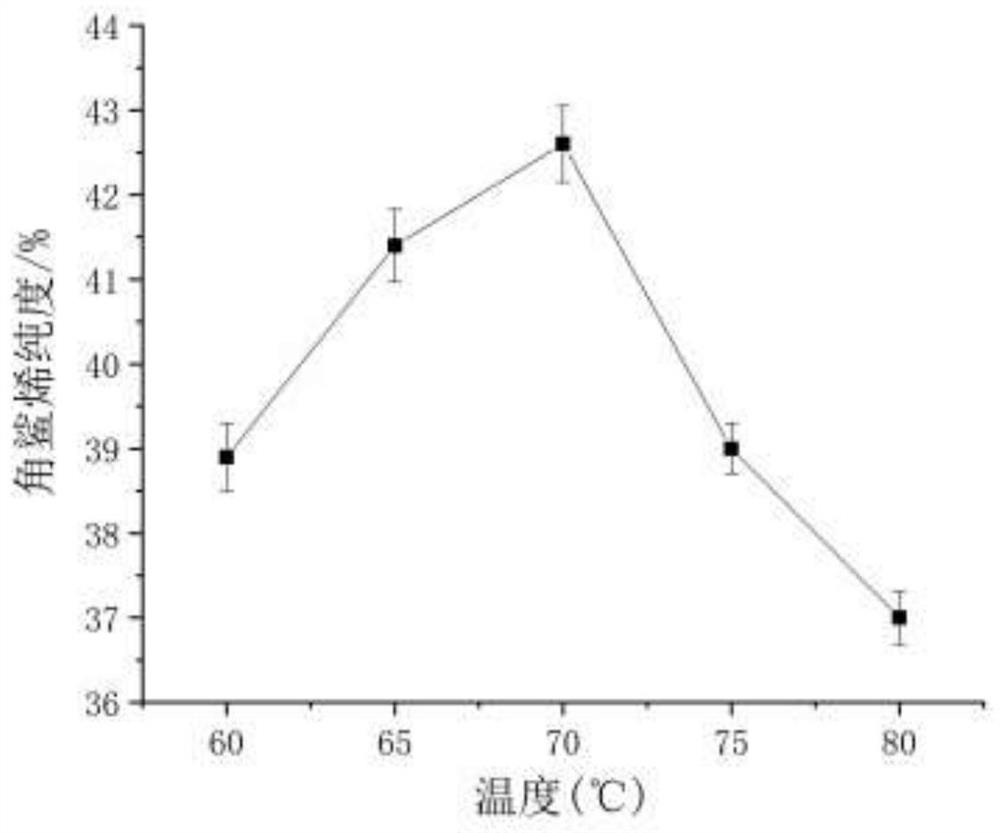

[0102] In the "extraction of unsaponifiable matter" in step 2), change it to: select 1.5mol / L potassium hydroxide-ethanol solution, and set the reaction temperature to 60, 65, 70, 75 and 80°C;

[0103] The rest are equal to Example 1.

[0104] The result is as image 3 shown.

[0105] Depend on image 3 It can be seen that when the reaction temperature is in the range of 60°C to 70°C, the purity of squalene increases as the temperature increases, but as the temperature continues to increase, the purity of squalene shows a trend of gradually decreasing. Analysis of its reason may be that when the temperature is low, the saponification reaction rate is slow, resulting in incomplete saponification, leaving too much fatty acid, thereby reducing the content of squalene; but when the temperature is too high, high temperature, alkaline reaction The environment can easily cause the structure of...

Embodiment 3

[0106] Embodiment 3, the method for preparing high purity from crude shark liver oil:

[0107] In the "extraction of unsaponifiable matter" in step 2), change it to: select 1.5mol / L potassium hydroxide-ethanol solution, and react at 70°C for a certain period of time (40, 50, 60, 70 and 80min). The rest are equal to Example 1.

[0108] The result is as Figure 4 shown.

[0109] Depend on Figure 4 It can be seen that the purity of squalene increases first and then decreases with the increase of reaction time. The reason for the analysis may be that the reaction time is too short and the saponification reaction is not complete; if the time is too long, high temperature and alkaline environment will destroy a large amount of squalene, thereby reducing the purity of squalene. At the time of 60min, the purity of squalene reached the highest. Therefore, the reaction time was 60 min for subsequent optimization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com