Preparation method and application method of cobalt-tellurium diatomic site catalyst

A diatomic and catalyst technology, applied in the field of electrocatalysis, can solve the problems of restricting large-scale application, high cost, and low reserves, and achieve the effect of excellent multifunctional catalytic performance, low cost, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 5.58g Zn(NO 3 ) 2 ·6H 2 O and 0.5 g of Te powder were dissolved in 150 mL of methanol to form solution A. 6.16 g of dimethylimidazole was dissolved in 150 mL of methanol to form clear solution B. Then, slowly pour solution B into solution A. After mixing and stirring at room temperature for 24 h, the precipitate was centrifuged, washed several times with methanol, and then dried at 60 °C to obtain a gray solid powder, which was recorded as Te 1 @ZIF-8.

[0037] The above Te 1 @ZIF-8 was dissolved in 50mL DMF to form solution C, 50mg tetraphenylporphyrin cobalt was dissolved in 50mL DMF to form solution D, then solution D was slowly added to solution C, mixed and stirred at room temperature for etching After 24 h of ion exchange, the precipitate was centrifuged, washed several times with ethanol, and then dried at 60 °C to obtain a beige solid powder, which was denoted as Co 0 -Te 1 @ZIF-8.

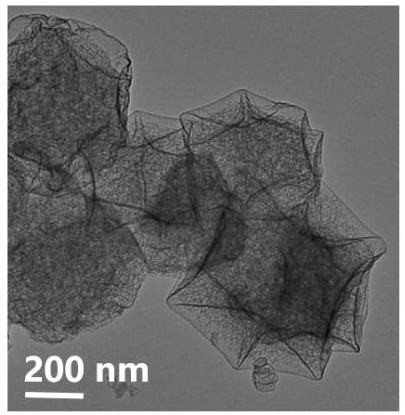

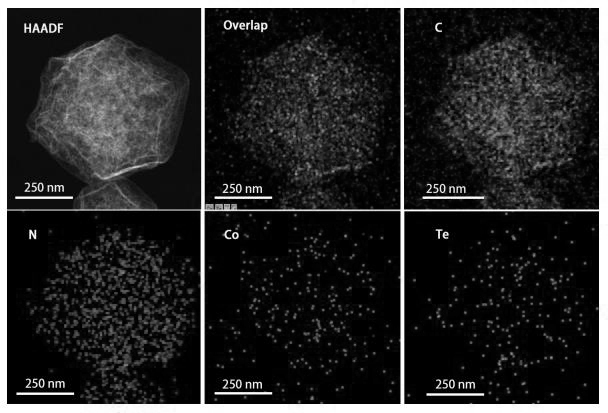

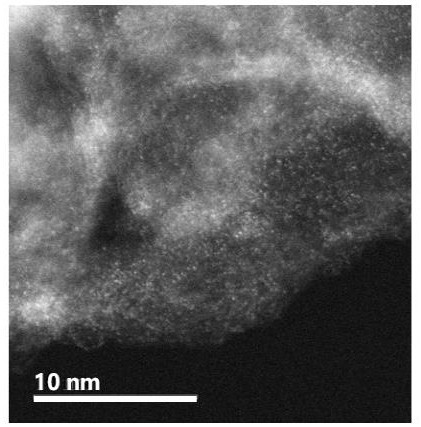

[0038] The above Co 0 -Te 1 @ZIF-8 was pyrolyzed at 920°C for 2 hour...

Embodiment 2

[0040] 5.58g Zn(NO 3 ) 2 ·6H 2O and 0.5 g of Te powder were dissolved in 150 mL of methanol to form solution A. 6.16 g of dimethylimidazole was dissolved in 150 mL of methanol to form clear solution B. Then, slowly pour solution B into solution A. After mixing and stirring at room temperature for 24 h, the precipitate was centrifuged, washed several times with methanol, and then dried at 60 °C to obtain a gray solid powder, which was recorded as Te 1 @ZIF-8.

[0041] The above Te 1 @ZIF-8 was dissolved in 50ml DMF to form solution C, 100mg tetraphenylporphyrin cobalt was dissolved in 50ml DMF to form solution D, then solution D was slowly added to solution C, mixed and stirred at room temperature for etching After 24 h of ion exchange, the precipitate was centrifuged, washed several times with ethanol, and then dried at 60 °C to obtain a gray-brown solid powder, which was recorded as Co-Te 1 @ZIF-8.

[0042] The above Co-Te 1 @ZIF-8 was pyrolyzed at 920°C for 2 hours ...

Embodiment 3

[0044] 5.58g Zn(NO 3 ) 2 ·6H 2 O and 1 g of Te powder were dissolved in 150 mL of methanol to form solution A. 6.16 g of dimethylimidazole was dissolved in 150 mL of methanol to form clear solution B. Then, slowly pour solution B into solution A. After mixing and stirring at room temperature for 24 h, the precipitate was centrifuged, washed several times with methanol, and then dried at 60 °C to obtain a gray solid powder, which was recorded as Te 2 @ZIF-8.

[0045] The above Te 2 @ZIF-8 was dissolved in 50ml DMF to form solution C, 100mg tetraphenylporphyrin cobalt was dissolved in 50ml DMF to form solution D, then solution D was slowly added to solution C, mixed and stirred at room temperature for etching After 24 h of ion exchange, the precipitate was centrifuged, washed several times with ethanol, and then dried at 60 °C to obtain a gray-brown solid powder, which was recorded as Co-Te 2 @ZIF-8.

[0046] The above Co-Te 2 @ZIF-8 was pyrolyzed at 920°C for 2 hours i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com