A preparation method of porous/hollow-like carbon black material for lithium-sulfur batteries

A lithium-sulfur battery, hollow technology, applied in lithium batteries, battery electrodes, fibrous fillers, etc., can solve the problems of production cost and process complexity, and achieve good application potential, excellent performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Embodiment 1: This embodiment illustrates the preparation method of the porous / hollow-like carbon black material used for lithium-sulfur batteries according to the following steps:

[0027] Take the carbon black material and concentrated nitric acid, add the concentrated nitric acid to the reaction kettle, then place the carbon black material on the separator, place the separator in the concentrated nitric acid and the upper surface of the separator is higher than the liquid level of the concentrated nitric acid, close the reaction After the hydrothermal reaction is completed, the solid product is washed with deionized water, and then filtered until the filtrate is neutral and colorless. The solid product after suction filtration is collected and dried to obtain a porous / hollow-like carbon black material.

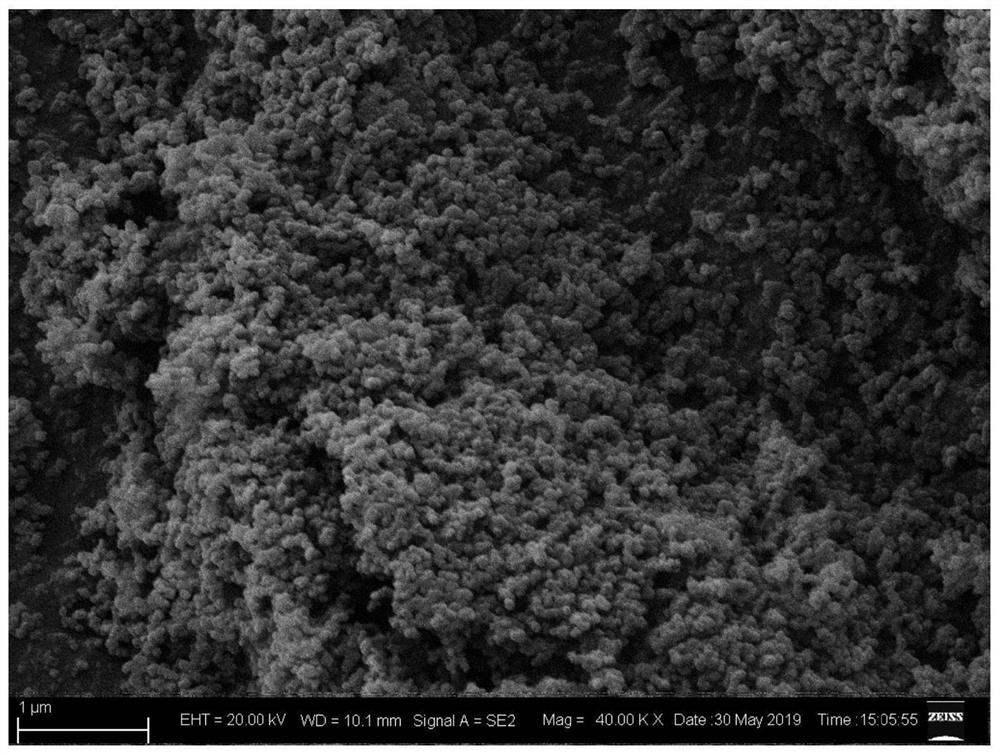

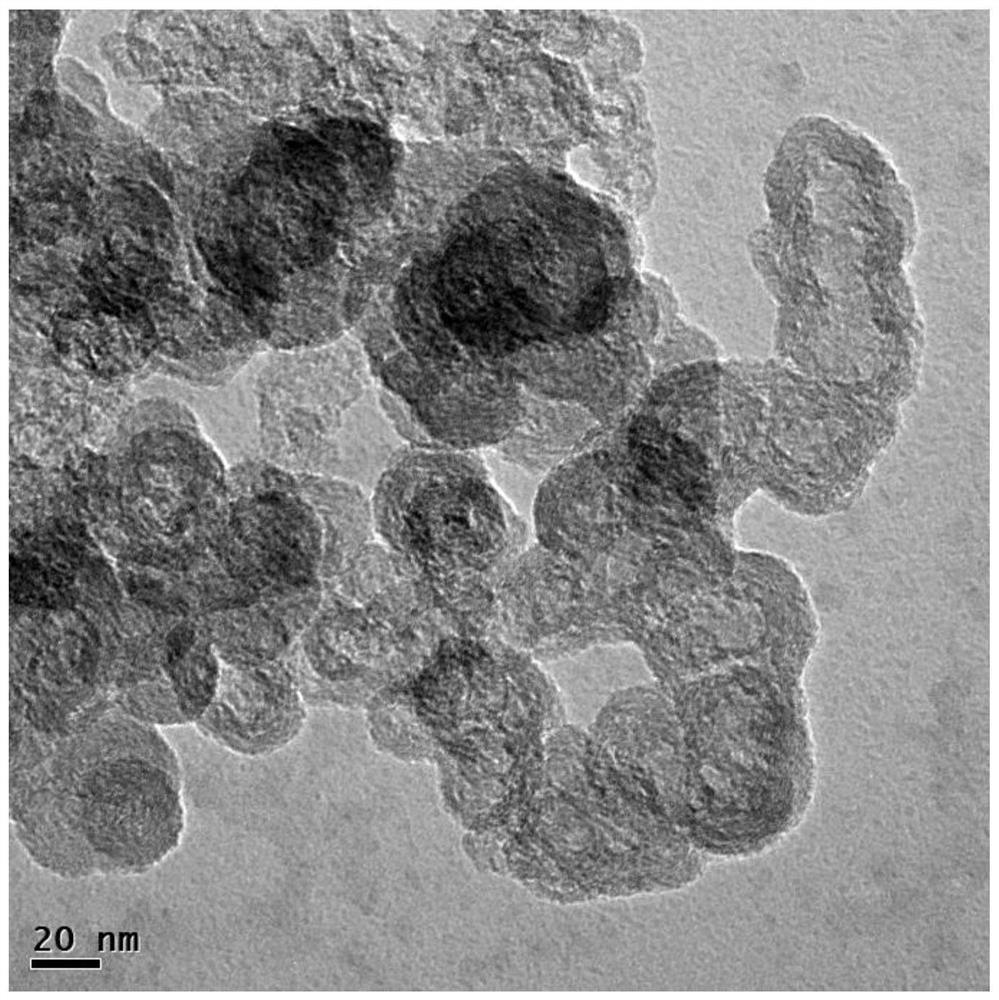

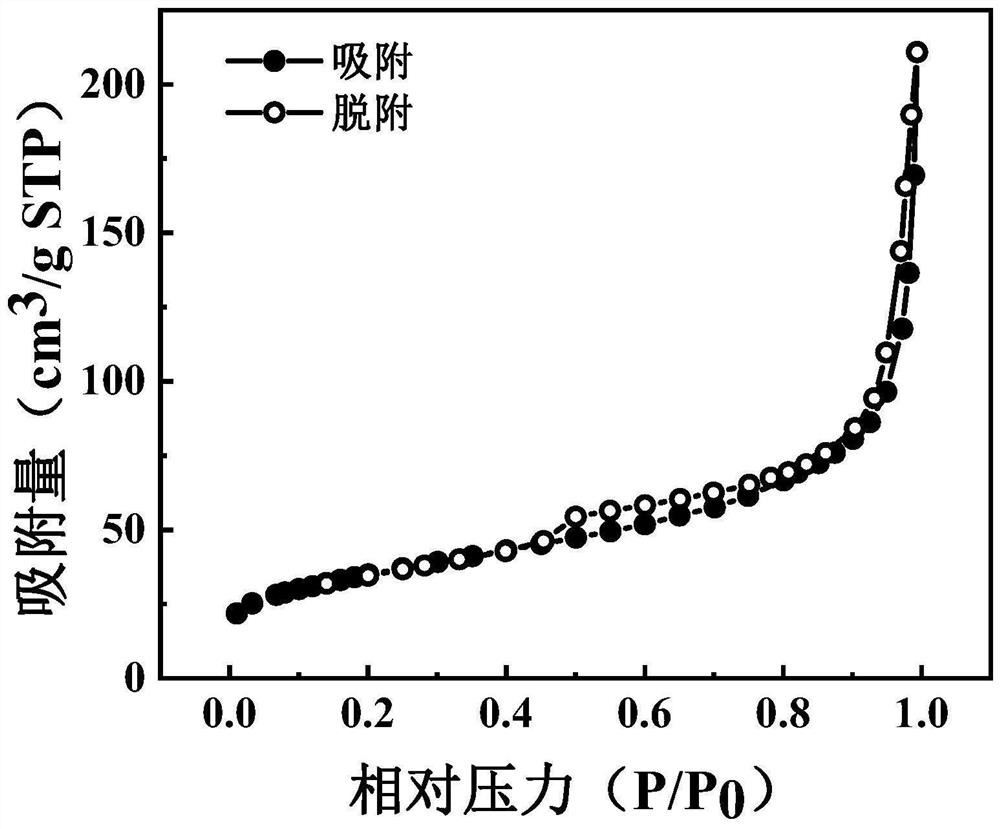

[0028] 1. This embodiment uses carbon black material as raw material. After hydrothermal treatment with concentrated nitric acid, porous or quasi-hollow structures c...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of the concentrated nitric acid is 65%-68%.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the carbon black material is SuperP, acetylene black or Ketjen black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com