Carbon-selenium composite material, preparation method thereof, and application thereof in lithium-selenium battery

A technology of composite materials and two-dimensional carbon materials, which is applied in the field of carbon-selenium composite materials and its preparation, can solve the problems of limited raw material sources and harsh preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0039] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

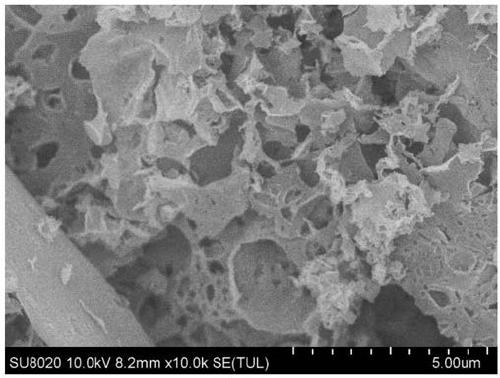

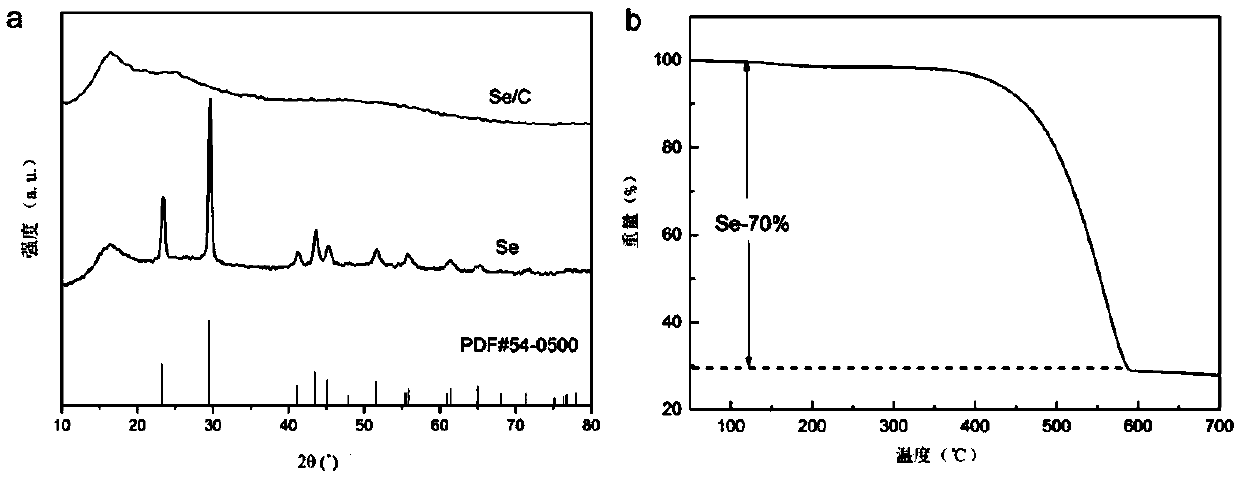

[0041] (1) Preparation of carbon-selenium composite materials

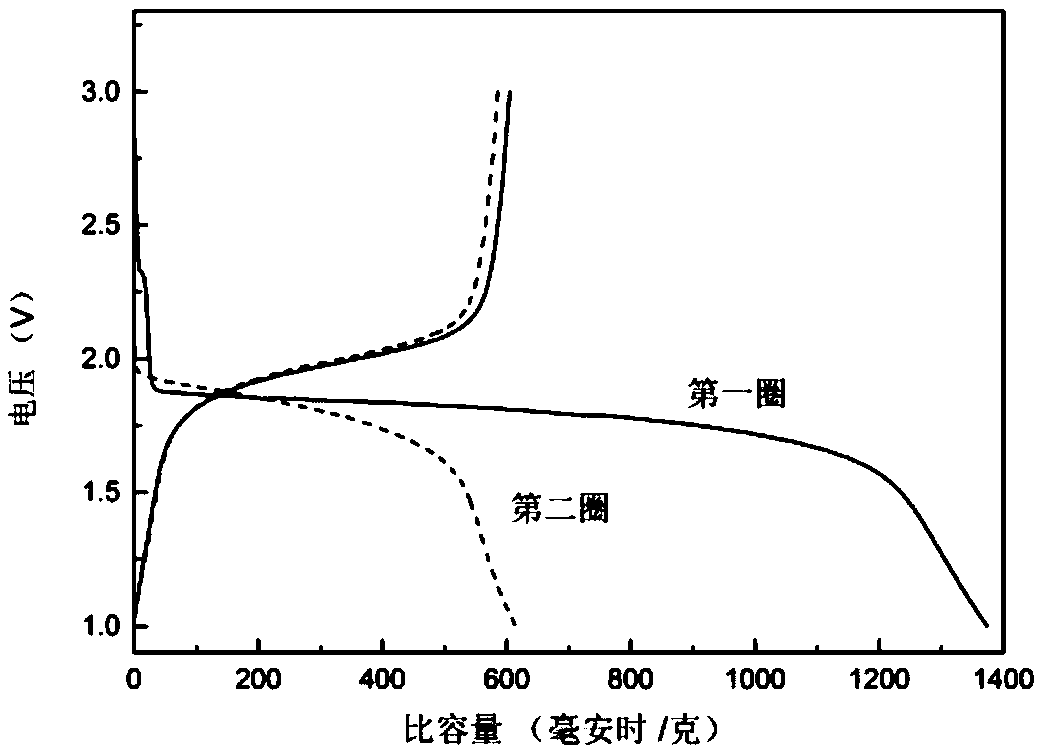

[0042] After grinding 4g of soluble starch and 6g of potassium oxalate, they were calcined at 900°C for 5h under an inert atmosphere, cooled to room temperature, and washed with dilute hydrochloric acid until neutral. Filtrate and dry to obtain a two-dimensional carbon nanomaterial; the two-dimensional carbon material and the ethanol solution of selenium with a concentration of 1mol / L are evenly stirred, wherein the two-dimensional carbon material and selenium are mixed according to a mass ratio of 30:70, and heated to the solvent Heat treatment after volatilization, and raise the temperature of the dried mixture to 240°C at a rate of 5°C / min for 15 hours under certain conditions; after cooling to room temperature, a carbon-selenium composite material is obtained, wherein the loading amount of selenium is 70wt%.

[0043] (2) Preparation of positive electrode sheet

[0044] The carbon-selenium composite material p...

Embodiment 2

[0054] Other conditions are the same as in Example 1, except that the raw material for carbonization is corn leaf, and the loading amount of simple selenium in the carbon-selenium composite material obtained by the method described in Experimental Example 2 is 70wt%. The battery test results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com