Micro-nano fiber warm-keeping floc with longitudinally variable density structure and preparation method thereof

A micro-nanofiber and nanofiber technology, applied in textiles, papermaking, adhesives, non-woven fabrics, etc., can solve problems such as slow process, poor mechanical properties of nanofibers, and damage to nanofiber layers, achieving high porosity and improving heat preservation performance, effect of small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

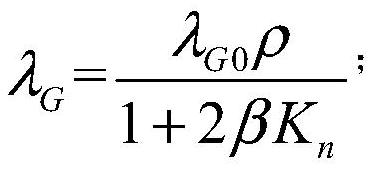

Method used

Image

Examples

preparation example Construction

[0054] A method for preparing a micro-nano fiber warm-keeping floc with a longitudinally variable density structure, comprising the following steps:

[0055] The first step: according to the different ratios required by the bottom layer fiber web, the middle layer fiber web and the surface layer fiber web, the initially opened micron fibers and nano fibers are further opened and mixed evenly by a pre-opener and a fine opener respectively to obtain Three different ratios of micro-nano mixed fiber raw materials;

[0056] Step 2: Using three vibrating cotton feeding machines, three kinds of mixed fiber raw materials with different proportions are made into uniform and dense mat cotton and fed to the carding machine respectively, and three kinds of thin fiber webs with different nanofiber contents are obtained by carding;

[0057] Step 3: Connect three web-laying machines in series, and lay webs corresponding to three types of thin webs with different nanofiber contents in the ord...

Embodiment 1

[0065] A method for preparing a micro-nano fiber warm-keeping floc with a longitudinally variable density structure, specifically: grabbing 25wt% of micron-sized thick hollow fibers, 55wt% of micron-sized fine fibers and 20wt% of nanofibers and mixing them uniformly at 850r Opening at the opening roller speed of / min, followed by carding to obtain the bottom fiber web and the surface layer fiber web; at the same time, grab 20wt% of micron-sized thick hollow fibers, 50wt% of micron-sized fine fibers and 30wt% of nanofibers and mix them evenly After opening, the speed of the opening roller is also 850r / min, followed by carding to obtain the middle layer fiber web. Among them, the micron-scale thick hollow fiber is a polyester fiber with a diameter of 22 μm, a hollowness of 75%, and a length of 33 mm; the micron-scale fine fiber is a polyethylene fiber with a diameter of 8 μm and a length of 32 mm; the nanofiber is ethyl cellulose The fiber is 300 nm in diameter and 30 mm in leng...

Embodiment 2

[0070] The same method as in Example 1 was used to prepare micro-nanofiber flakes, wherein the micron-sized thick hollow fibers of the bottom fiber web and the surface layer fiber web accounted for 28wt%, micron-sized fine fibers accounted for 52wt%, and nanofibers accounted for 20wt% ; The fiber net of the middle layer accounts for 22wt% of the thick hollow fibers of the micron scale, 47wt% of the fine fibers of the micron scale, and 31wt% of the nanofibers. Micron-sized thick hollow fibers are polypropylene fibers with a diameter of 25 μm, a hollowness of 73%, and a length of 31 mm; micron-sized fine fibers are polyaniline fibers with a diameter of 9 μm and a length of 33 mm; nanofibers are polystyrene fibers with a diameter of It is 350nm and the length is 31mm. The opening roller speed is 900r / min, the web laying speed is 23m / min, the composite fiber web layer is output at a speed of 6m / min, and the PVC adhesive is 16g / m 2 The amount of spraying is added to the composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com