Photocuring oil phase for preparing photocuring droplet array chip, and preparation method, product and application of photocuring droplet array chip

An array chip, light curing technology, applied in chemical instruments and methods, biochemical equipment and methods, laboratory containers, etc., can solve the problems of increasing the complexity of ddPCR, slow curing, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

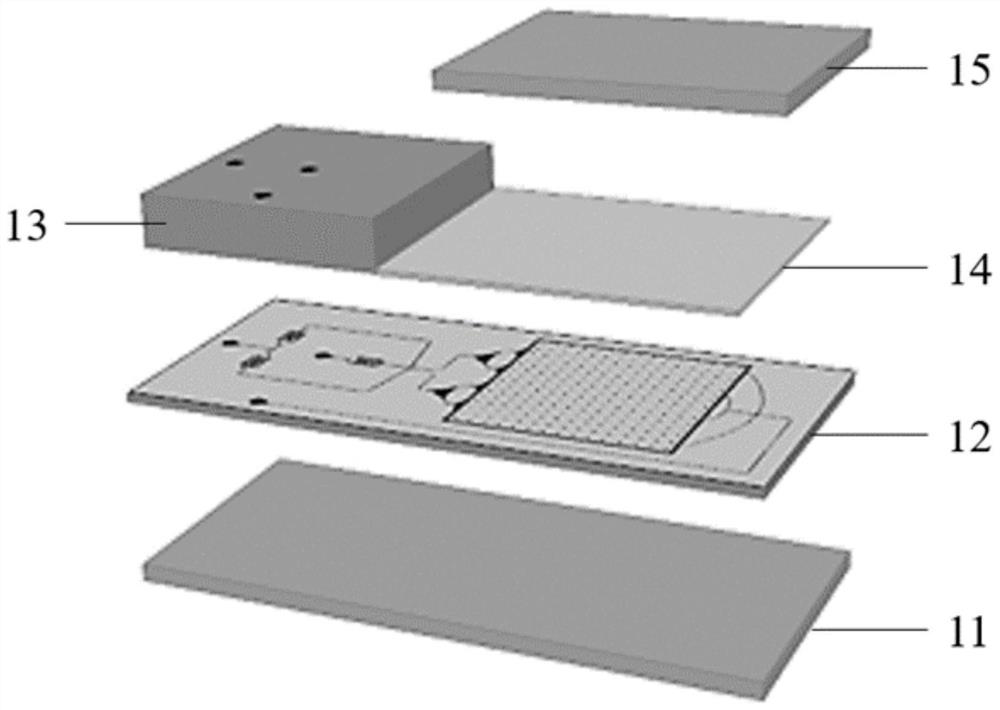

[0119] Step 1. Processing of the main body of the microfluidic chip:

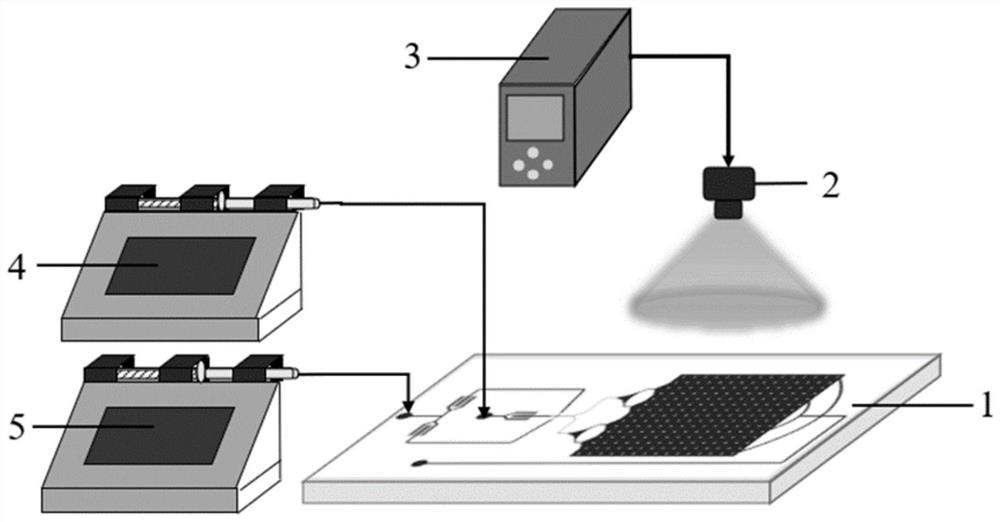

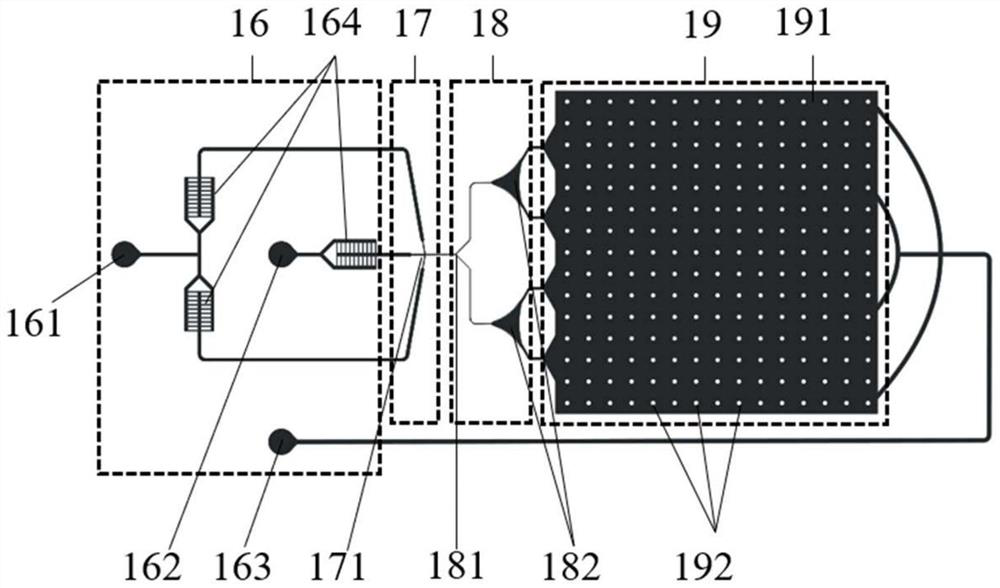

[0120] a) According to the channel structure of the main body of the microfluidic chip (such as image 3 ) custom masks;

[0121] b) Spin-coat photoresist (Microchem, SU-8 3025) on a clean single crystal silicon wafer with a thickness of 50 μm;

[0122] c) placing the mask on the silicon wafer coated with photoresist, and exposing it on an ultraviolet lithography machine;

[0123] d) developing, removing excess photoresist, and obtaining a mold with a photoresist pattern;

[0124] e) Mix the PDMS prepolymer and curing agent (Dow Corning, Sylgard184) in a ratio of 10:1, stir evenly, pour 6g onto the mold, and spin-coat it into a film with a thickness of 450 μm;

[0125] f) placing the mold spin-coated with a PDMS film with a thickness of 450 μm in step (e) on a heating plate for heating and curing;

[0126] g) Seal the blank PDMS support module to the top of the sample inlet and sample outlet area of t...

Embodiment 2~4

[0146] The same process flow and raw material composition as in Example 1 are adopted, the only difference is that in step 4, the flow rate of the continuous phase is replaced by 100 μL / h, 60 μL / h, and 40 μL / h in sequence, and the diameters of the obtained droplets are 52 μm, 58μm vs. 72μm.

Embodiment 5

[0148] Using the same process flow as in Example 2, the only difference is that the raw material composition of the photocurable oil phase prepared in step 3 is different, specifically: by volume percentage, 91.5% polysiloxane acrylate (Gelest, UMS- 182), 5% stearate methacrylate (Sigma, 411442), 3% surfactant (Dow Corning, DC5225C), 0.5% photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1 - Prepared by mixing acetone (Sigma, 405655).

[0149] After testing, this embodiment can generate stable droplets, and after the oil phase solidifies, the droplet array is fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com