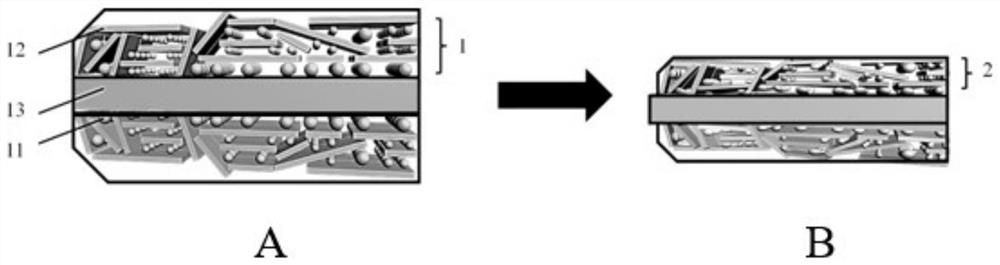

Preparation method of porous anode aluminum foil with multi-stage mixed structure

A mixed structure, porous anode technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of small electrostatic capacity of electrode foil, and achieve the goal of improving flashover voltage, low leakage current and large specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

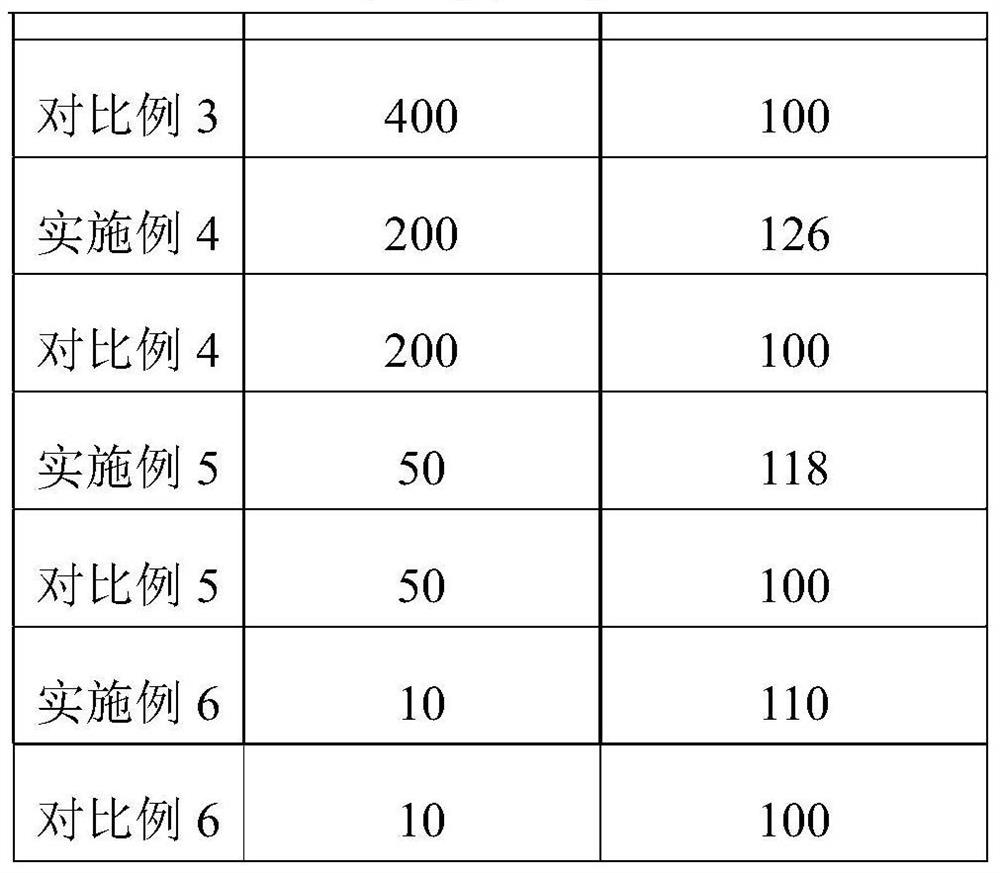

[0040] Mix fibrous aluminum metal with an average particle size of 20 μm (purity above 99.99%) and aluminum metal particles (ellipsoid) with an average particle size of 500 nm at a ratio of 20:1 to obtain a mixed raw material, and mix the raw material and acrylic resin by 1 :1 mass ratio is mixed, and the mixture is dispersed in toluene to form a 60% dispersion and the dispersion is coated on a 40 μm aluminum foil, sintered at 600 ° C under vacuum, and finally in 3% boric acid solution (60 ℃) anodized to 1000V. Anodizing condition: 150mA·cm -2 , constant pressure for at least 10 minutes, annealing in air at 600°C for 2-5 minutes, and shape correction for 5 minutes.

[0041] The electrode foil prepared according to the method described in this example was tested for electrostatic capacitance with an LCR meter, and the results are shown in Table 1.

Embodiment 2

[0043] Mix ribbon-shaped aluminum metal material (purity above 99.99%) with an average particle size of 10 μm and aluminum metal particles (spherical) with an average particle size of 200 nm at a ratio of 10:1 to obtain a mixed raw material, mix the raw material and ethyl cellulose Mix according to the mass ratio of 2:1, and disperse the mixture into trichloroethane to form a 60% dispersion and coat the dispersion on a 35μm aluminum foil, sinter at 550°C under vacuum, and finally in 5% Anodized to 800V in boric acid solution (60°C). Anodizing condition: 100mA·cm -2 , constant pressure for at least 10 minutes, annealing in air at 550°C for 2-5 minutes, and shape correction for 5 minutes.

[0044] The electrode foil prepared according to the method described in this example was tested for electrostatic capacity by using an LCR meter, and the results are shown in Table 1.

Embodiment 3

[0046] Mix aluminum flakes (purity above 99.99%) with an average particle size of 5 μm and aluminum metal particles (block shape) with an average particle size of 50 nm in a ratio of 0.5:1 to obtain a mixed raw material, mix the raw material and ethyl cellulose in 3 :1 mass ratio for mixing and dispersing the mixture into methyl ethyl ketone to form a 50% dispersion and coating the dispersion on a 35 μm aluminum foil, sintering at 500°C under vacuum, and finally in 10% of Anodized to 400V in boric acid solution (85°C). Anodizing condition: 50mA·cm -2 , constant pressure for at least 10 minutes, annealing in air at 500°C for 2-5 minutes, and shape correction for 5 minutes.

[0047] The electrode foil prepared according to the method described in this example was tested for electrostatic capacitance with an LCR meter, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com