Novel fluorinated silicone rubber additive as well as preparation method and application thereof

A technology of fluorosilicone rubber and additives, applied in chemical instruments and methods, silicone organic compounds, organic chemistry, etc., can solve the problems of increasing dosage, resilience, small compression set, and rubber becoming brittle, etc. The effect of cross-linking reaction, improving reaction probability, and increasing vulcanization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

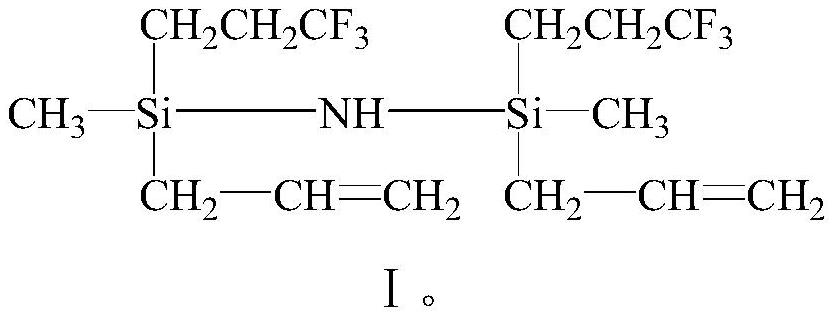

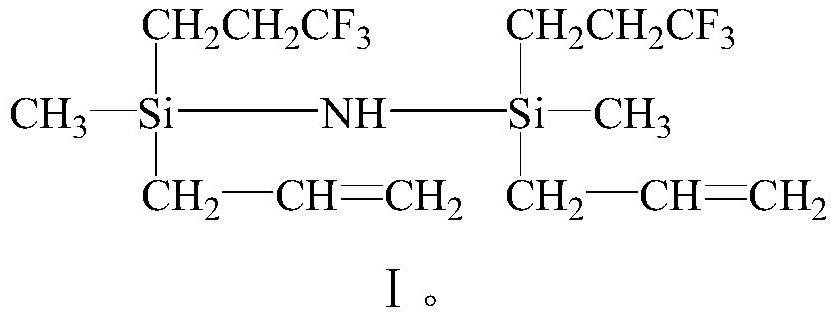

Method used

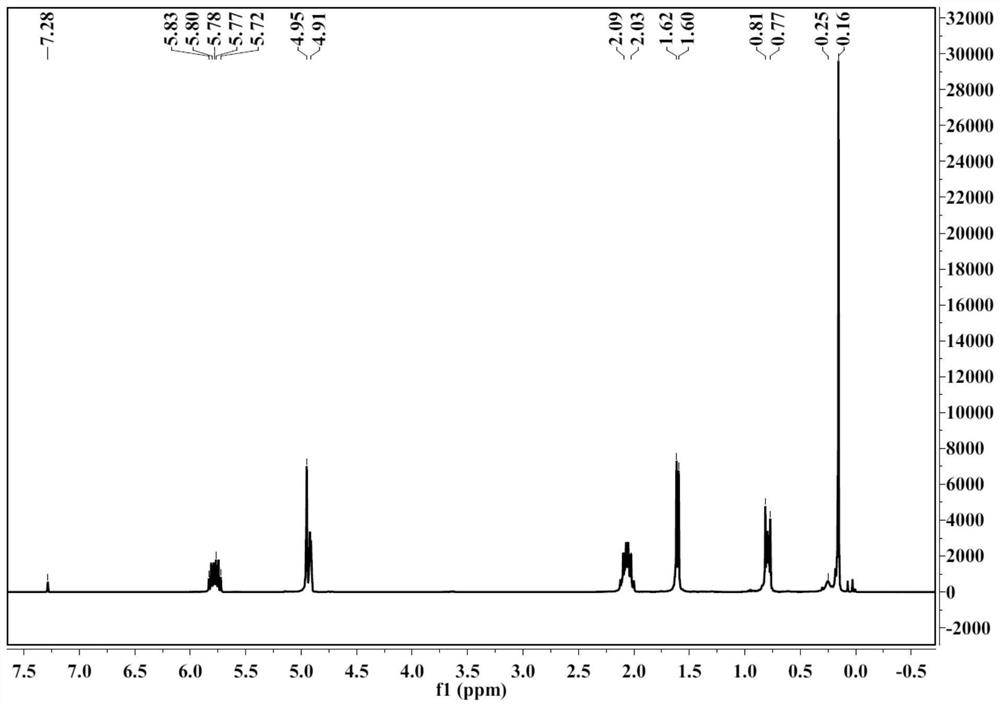

Image

Examples

Embodiment 1

[0049] A preparation method of a novel fluorosilicone rubber additive, comprising the steps of:

[0050] (1) Preparation of Trifluoropropyl Allyl Methyl Chlorosilane

[0051] Add dried THF1000g, trifluoropropylmethyldichlorosilane 1265g, 80g Mg scraps and 0.5g iodine to remove the oxide layer in the reactor with mechanical stirring, constant pressure dropping funnel, thermometer and spherical condenser, Stir and mix evenly; take 790g of dry THF and 228g of allyl chloride and mix them evenly and add them to the constant pressure dropping funnel. 30~40℃, the dropping time is 3h, after the dropping is completed, react at 30~40℃ for 1h; After filtration, the filtrate was rectified and purified with a reflux ratio of 7:1, and the fraction at 63-65°C / 10.1kPa was cut off to obtain trifluoropropylallylmethylchlorosilane with a purity of 99.0% and a yield of 84%.

[0052] (2) Preparation of bis(trifluoropropyl)bis(allyl)dimethyldisilazane

[0053] Add 400g of n-hexane and 200g of tr...

Embodiment 2

[0058] A preparation method of a novel fluorosilicone rubber additive, comprising the steps of:

[0059] (1) Preparation of Trifluoropropyl Allyl Methyl Chlorosilane

[0060] Add dried THF1000g, trifluoropropylmethyldichlorosilane 1265g, 80g Mg scraps and 0.5g iodine to remove the oxide layer in the reactor with mechanical stirring, constant pressure dropping funnel, thermometer and spherical condenser, Stir and mix evenly; take 790g of dry THF and 363g of propylene bromide and mix them evenly and add them to the constant pressure dropping funnel. At 30-40°C, the dropping time is 3h. After the dropwise addition, react at 30-40°C for 1h; After filtration, the filtrate was rectified and purified with a reflux ratio of 7:1, and the fraction at 63-65°C / 10.1kPa was cut off to obtain trifluoropropylallylmethylchlorosilane with a purity of 98.7% and a yield of 81%.

[0061] (2) Preparation of bis(trifluoropropyl)bis(allyl)dimethyldisilazane

[0062] Add 500g of cyclohexane and 200...

Embodiment 3

[0064] A preparation method of a novel fluorosilicone rubber additive, comprising the steps of:

[0065] (1) Preparation of Trifluoropropyl Allyl Methyl Chlorosilane

[0066] Add dried THF1000g, trifluoropropylmethyldichlorosilane 1265g, 54g Mg chips and 0.5g iodine to remove the oxide layer in the reactor with mechanical stirring, constant pressure dropping funnel, thermometer, and spherical condenser, Stir and mix evenly; take 500g of dry THF and 153g of allyl chloride and mix them evenly, and then add them to the constant pressure dropping funnel. At 30-40°C, the dropping time is 3h. After the dropping is completed, react at 30-40°C for 1h; After filtration, the filtrate was purified by rectification at a reflux ratio of 7:1, and the fraction at 63-65°C / 10.1kPa was cut off to obtain trifluoropropylallylmethylchlorosilane with a purity of 99.4% and a yield of 89%.

[0067] (2) Preparation of bis(trifluoropropyl)bis(allyl)dimethyldisilazane

[0068] Add 600g of toluene and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com