A kind of preparation method of single crystal large particle of ternary material

A ternary material, large particle technology, applied in electrical components, electrode manufacturing, structural parts, etc., can solve the problems of incomplete combination of main metal elements released by carbonate, large amount of additives, waste, etc., to prevent particle growth. Uniform phenomenon, the effect of preventing uneven distribution of flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

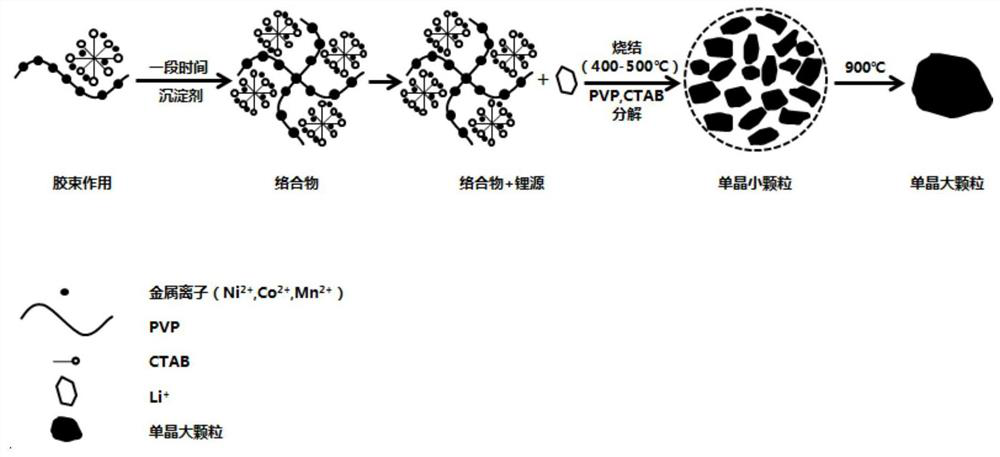

Method used

Image

Examples

Embodiment 1

[0046] The reaction mechanism for preparing NCM523 precursor is as follows:

[0047] NH 2 CONH 2 +H 2 O→2NH 3 +CO 2 (1)

[0048] NH 3 +H 2 O→NH 4 + +OH- (2)

[0049] CO 2 +OH - →CO 3 2- +H 2 O (3)

[0050] 0.5Ni 2+ +0.2Co 2+ +0.3Mn 2+ +CO 3 2- →Ni 0.5 co 0.2 mn 0.3 CO 3 (4)

[0051] Ni 0.5 co 0.2 mn 0.3 CO 3 +Li + +1 / 2O 2 →LiNi 0.5 co 0.2 mn 0.3 o 2 +CO 2 (5)

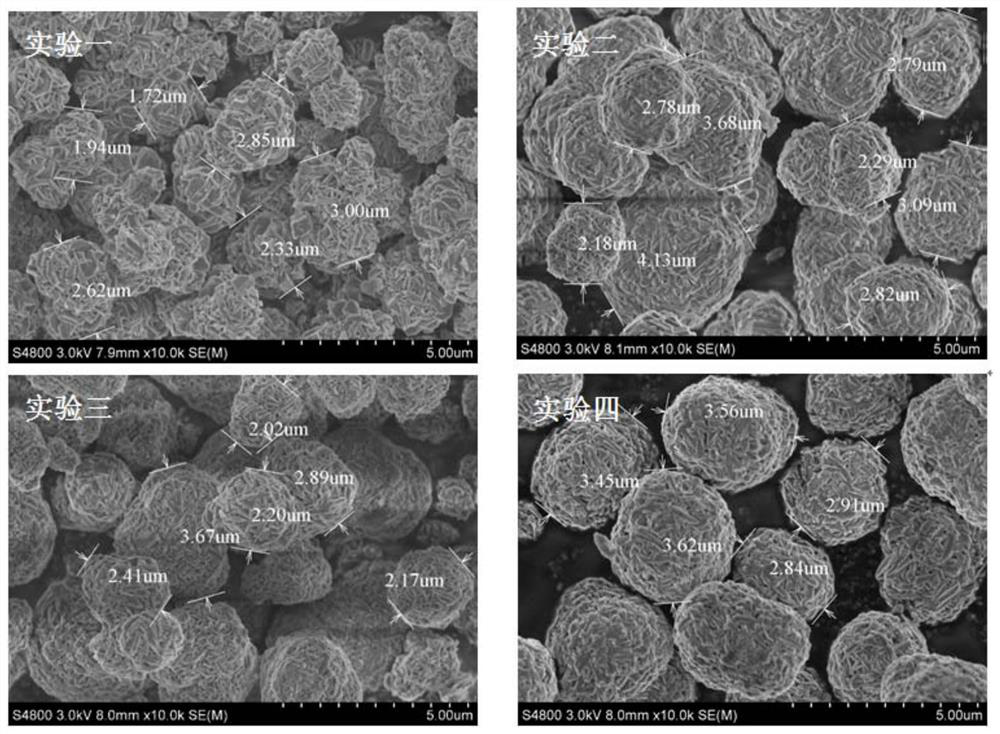

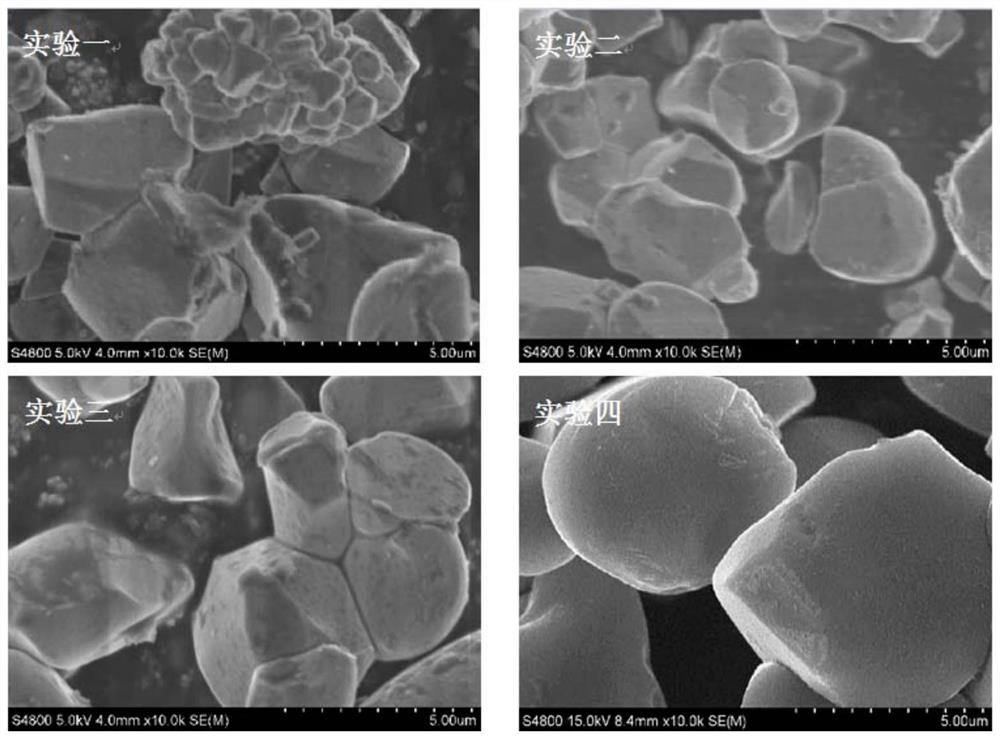

[0052] Table 1. NCM523 (LiNi 0.5 co 0.2 mn 0.3 o 2 ) Experimental scheme for the preparation of large single crystal particles

[0053]

[0054] Experimental steps:

[0055] (1) Prepare 4 beakers marked as 1#, 2#, 3#, 4#, and weigh 100mL deionized water respectively;

[0056] (2) template agent 1 and 2 of experimental scheme in table 1, fluxing agent are dissolved in 1#, 2#, 3#, 4# beaker according to scheme respectively to obtain mixed solution;

[0057] (3) then take cobalt source, nickel source and manganese source respectively according to the amount calculated in ta...

Embodiment 2

[0062] Table 2. NCM622 (LiNi 0.6 co 0.2 mn 0.2 o 2 ) Experimental scheme for the preparation of large single crystal particles

[0063]

[0064] Experimental steps:

[0065] (1) Prepare 4 beakers marked as 1#, 2#, 3#, 4#, and weigh 200mL deionized water respectively;

[0066] (2) template agent 1 and 2 of experimental scheme in table 1, fluxing agent are dissolved in 1#, 2#, 3#, 4# beaker according to scheme respectively to obtain mixed solution;

[0067] (3) then take cobalt source, nickel source and manganese source respectively according to the amount calculated in table 1 and be respectively placed in 1#, 2#, 3#, 4# beakers and fully dissolve to obtain metal mixed solution;

[0068] (4) Finally, put the urea calculated in Table 1 into the mixed metal solution, fully dissolve it, transfer it to a hydrothermal reaction kettle, and place the sealed reaction kettle in an oven at 200°C for 16 hours to obtain the NCM622 precursor solution;

[0069] (5) After filtering, ...

Embodiment 3

[0072] Table 3. NCM811 (LiNi 0.8 co 0.1 mn 0.1 o 2 ) Experimental scheme for the preparation of large single crystal particles:

[0073]

[0074] Experimental steps:

[0075] (1) Prepare 4 beakers marked as 1#, 2#, 3#, 4#, and weigh 180mL deionized water respectively;

[0076] (2) template agent 1 and 2 of experimental scheme in table 1, fluxing agent are dissolved in 1#, 2#, 3#, 4# beaker according to scheme respectively to obtain mixed solution;

[0077] (3) then take cobalt source, nickel source and manganese source respectively according to the amount calculated in table 1 and be respectively placed in 1#, 2#, 3#, 4# beakers and fully dissolve to obtain metal mixed solution;

[0078] (4) Finally, put the urea calculated in Table 1 into the mixed metal solution, fully dissolve it, transfer it to a hydrothermal reactor, and place the sealed reactor in an oven at 180°C for 12 hours to obtain the NCM811 precursor solution;

[0079] (5) After the precursor solution syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com