Reinforced and antibacterial plastic masterbatch based on artificial agglomerated stone waste residues and preparation method thereof

A technology of artificial granite and plastic masterbatch, which is applied in the field of environmental protection and reuse of construction waste, can solve problems such as not giving prompts, achieve the effects of improving mechanical strength, realizing large-scale application, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

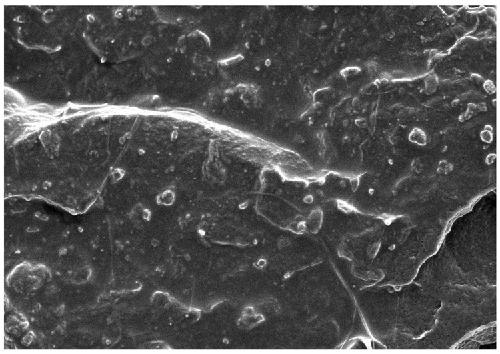

Image

Examples

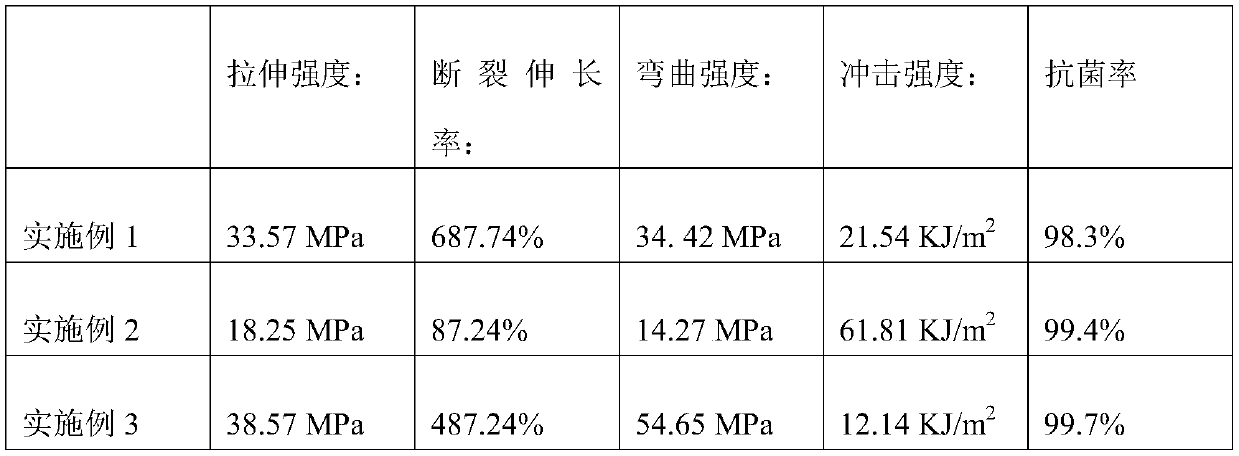

Embodiment 1

[0044] Raw materials are prepared in the following parts by weight: 100 parts of polyethylene, 650 parts of artificial granite waste residue, 100 parts of 1200 mesh needle-shaped light calcium carbonate, 50 parts of long glass fibers, stearic acid-aluminate (the weight ratio is 3 / 1 ) compound modifier 3.5 parts, chain extender JONCRYL ADR 4370-S 1 part, compatibilizer maleic anhydride grafted ethylene-vinyl acetate copolymer (MAH-g-EVA) 3 parts, antibacterial agent nano ZnO 15 parts , 1 part of polyethylene wax as lubricant, 1.5 parts of ethoxylated lauric acid amine as antistatic agent.

[0045] Step 1. Wet grinding and drying treatment of artificial granite waste residue:

[0046] (1) adding water to the artificial granite waste residue to prepare a slurry with a solid content of 20%, then adding 1.2 parts by weight of sodium polyacrylate with a molecular weight of 2500, and stirring to form a uniform slurry;

[0047] (2) The above-mentioned slurry is input into a grinding ...

Embodiment 2

[0060] Raw materials are prepared in the following parts by weight: 100 parts of polyvinyl chloride, 800 parts of artificial granite waste residue, 100 parts of 1500 mesh titanium dioxide, 5 parts of carbon fiber, stearic acid / titanate (weight ratio is 5 / 1) composite modifier 10 3 parts, chain extender JONCRYL ADR4468 3 parts, compatibilizer EPDM rubber 4 parts, antibacterial agent nano-silver 1 part, lubricant paraffin 2 parts, antistatic agent ethoxylated lauric acid amine 2.5 parts.

[0061] Step 1. Drying and crushing treatment of artificial granite waste residue:

[0062] (1) Drying and pulverizing the artificial granite waste residue raw material through a rotary flash dryer, wherein the inlet air temperature of the flash dryer is 210°C, and the outlet air temperature is 105°C;

[0063] (2) When the water content of the artificial granite waste slag is 1.0%, the drying is stopped and the flash evaporation treatment can be obtained to obtain the artificial granite waste r...

Embodiment 3

[0071] Raw materials are prepared in the following parts by weight: 100 parts of polypropylene, 300 parts of artificial granite waste residue, 100 parts of 800 mesh kaolin, 200 parts of glass microspheres, stearic acid-boric acid ester (weight ratio is 2 / 1) composite modifier 0.2 parts, chain extender JONCRYL ADR4400 5 parts, compatibilizer maleic anhydride grafted styrene-ethylene-butylene-styrene block copolymer (MAH-g-SEBS) 3 parts, antibacterial agent nano-silver 25 parts, Lubricant paraffin 0.3 part, antistatic agent sodium dodecylbenzene sulfonate 0.5 part.

[0072] Step 1. Drying and crushing treatment of artificial granite waste residue:

[0073] (1) Drying and pulverizing the artificial granite waste residue raw material through a rotary flash dryer, wherein the inlet air temperature of the flash dryer is 240°C, and the outlet air temperature is 110°C;

[0074] (2) When the water content of the artificial granite waste slag is 1.25%, the drying is stopped and the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com