Plastic panel vapor chamber and making method thereof

A manufacturing method and vapor chamber technology, applied in the field of heat exchange, can solve the problems of affecting vacuuming and filling, easy to be crushed, and high mold complexity, so as to reduce the number and cost of molds, reduce processing and manufacturing costs, and improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

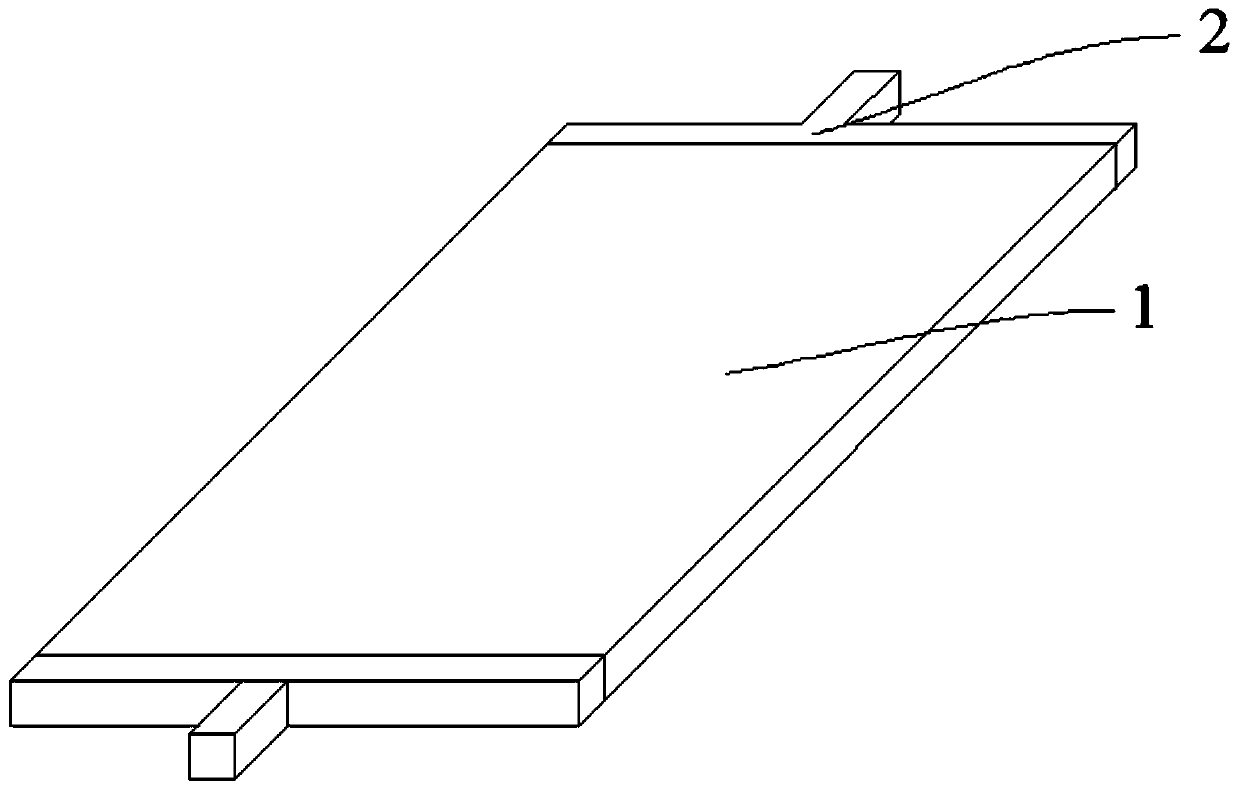

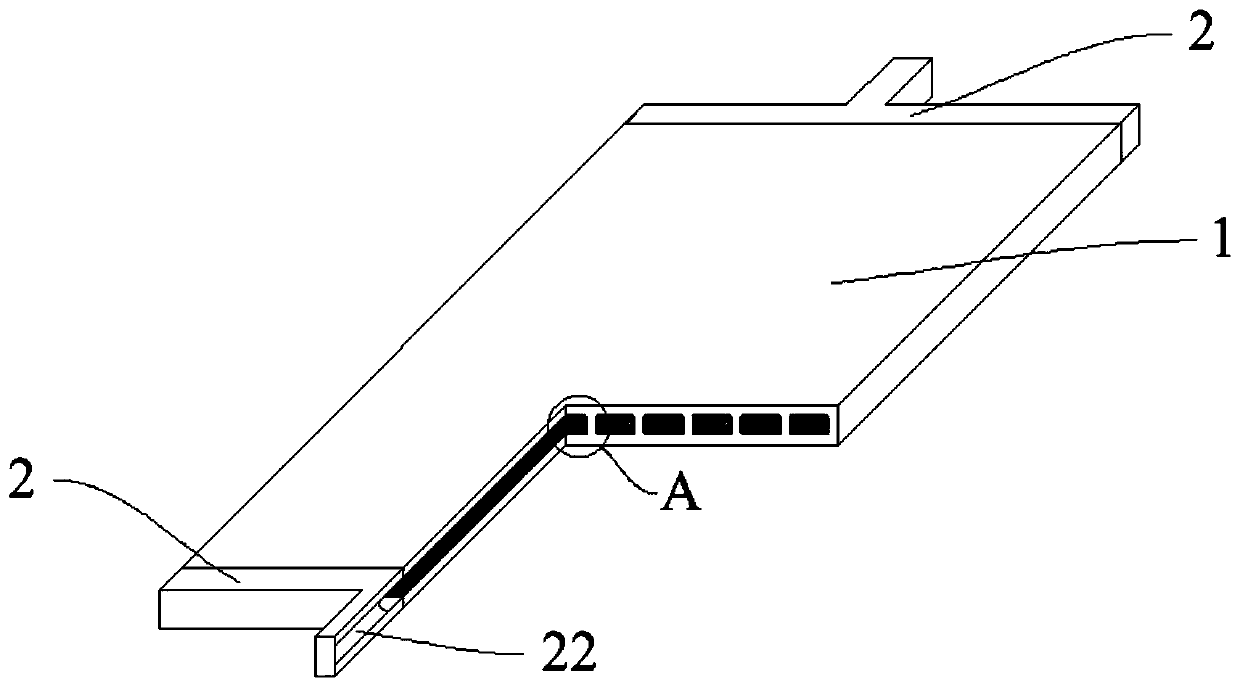

[0052] Such as Figure 1 ~ Figure 4 The shown one plastic flat vapor chamber includes: a cavity 1 and an encapsulation part 2, the cavity 1 cooperates with two encapsulation parts 2 at both ends to seal the cavity 1, and the inside of the cavity 1 is evacuated and filled with The cavity 1 is provided with a support structure 11, the cavity 1 is divided into several heat dissipation channels through the support structure 11, the surface of the heat dissipation channel in the cavity 1 is provided with a capillary structure 12, and the communication cavity 21 divides several heat dissipation channels. The channels communicate with each other, so that the working fluid can transfer heat to all parts of the entire vapor chamber faster, improving the heat transfer efficiency.

[0053] The capillary structure 12 on the surface of the support structure 11 is a microgroove parallel to the direction of the heat dissipation channel; the working fluid is acetone, which can absorb heat and...

Embodiment 2

[0068] Such as Figure 5 A flat plastic soaking plate shown has the same structure as that of Embodiment 1, the difference is that the outer surface of the cavity 1 is provided with a plurality of heat dissipation fins 3, and the material of the heat dissipation fins 3 is the same as that of the cavity heat-conducting plastic, a plurality of cooling fins 3 are arranged along the longitudinal direction of the cavity (that is, in the same direction as the cooling channel in the cavity 1), and the cooling fins 3 are parallel to each other, and the plurality of cooling fins 3 and the cavity 1 Integrated extrusion molding. It can reduce the processing procedure of the flat vapor chamber, greatly improve the production efficiency, reduce the cost and improve the heat dissipation performance. In addition, in this embodiment, the vacuumizing and filling steps of the working fluid can be as follows: connect the working medium filling equipment and the vacuuming equipment to the two en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com