Antibacterial HDPE plastic chair suitable for outdoor use and preparation method thereof

A plastic and outdoor technology, applied in the field of plastic chairs, can solve the problems of high human toxicity, poor temperature resistance, environmental pollution, etc., and achieve the effect of good processing performance, good stability and dispersion, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

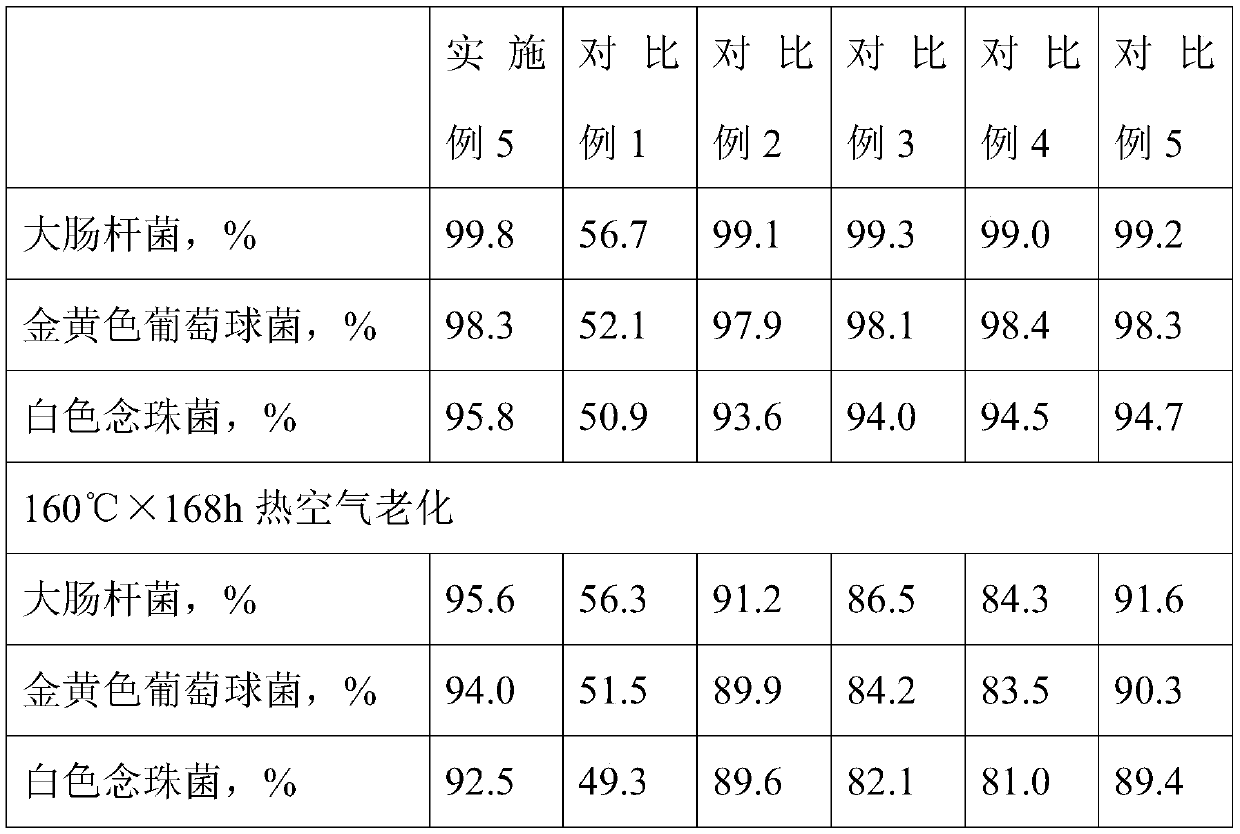

Examples

Embodiment 1

[0026] An antibacterial HDPE plastic chair suitable for outdoor use, its raw materials include: high-density polyethylene 100kg, polypropylene 15kg, ethylene-vinyl acetate copolymer 6kg, carboxylated polypropylene 1kg, cedar oil 2kg, epoxy soybean oil 0.5kg , sodium stearate 1kg, magnesium oxide 1kg, highly stable antibacterial agent 4kg, vinyl succinic anhydride grafted polypropylene 1kg, diphenylamine 2kg, phenyl o-hydroxybenzoate 1kg.

[0027] The melt flow rate (230°C / 2.16kg) of polypropylene is 90g / 10min, and the density is 0.88g / cm 3 .

[0028] The highly stable antibacterial agent is prepared by the following process: 30kg of attapulgite is sent into a drying furnace, roasted at a temperature of 500°C, cooled to obtain calcined attapulgite with a density of 0.74g / cm3, crushed through a 100-mesh sieve, and sent into a 100kg In a hydrochloric acid solution with a concentration of 5mol / L, stir at a temperature of 80°C for 1h, filter, wash, dry, and send it into an ethanol...

Embodiment 2

[0034] An antibacterial HDPE plastic chair suitable for outdoor use, its raw materials include: high-density polyethylene 100kg, polypropylene 25kg, ethylene-vinyl acetate copolymer 2kg, carboxylated polypropylene 2kg, cedar oil 1kg, epoxy soybean oil 1.2kg , sodium stearate 0.2kg, magnesium oxide 2kg, highly stable antibacterial agent 2kg, acrylic acid grafted polypropylene 2kg, p-phenylenediamine 1kg, 2-hydroxy-4-methoxybenzophenone 2kg.

[0035] The melt flow rate (230°C / 2.16kg) of polypropylene is 96g / 10min, and the density is 0.85g / cm 3 .

[0036] The highly stable antibacterial agent is prepared by the following process: 20kg of attapulgite is sent into a drying furnace, roasted at a temperature of 600°C, cooled to obtain calcined attapulgite with a density of 0.7g / cm3, crushed through a 200-mesh sieve, and sent into a 50kg In a hydrochloric acid solution with a concentration of 5.6mol / L, stir at a temperature of 70°C for 2h, filter, wash, dry, and send it into a soluti...

Embodiment 3

[0042] An antibacterial HDPE plastic chair suitable for outdoor use, its raw materials include: high-density polyethylene 100kg, polypropylene 18kg, ethylene-vinyl acetate copolymer 5kg, carboxylated polypropylene 1.3kg, cedar oil 1.8kg, epoxy soybean oil 0.6kg, sodium stearate 0.8kg, magnesium oxide 1.3kg, highly stable antibacterial agent 3.5kg, citraconic anhydride grafted polypropylene 1.2kg, N-isopropyl-N'-phenyl-p-phenylenediamine 1.7kg, Phenyl o-hydroxybenzoate 1.2kg.

[0043] The melt flow rate (230°C / 2.16kg) of polypropylene is 92g / 10min, and the density is 0.87g / cm 3 .

[0044] The highly stable antibacterial agent is prepared by the following process: 26kg of attapulgite is sent into a drying furnace, roasted at a temperature of 530°C, cooled to obtain calcined attapulgite with a density of 0.73g / cm3, crushed through a 140-mesh sieve, and sent into 80kg In a hydrochloric acid solution with a concentration of 5.2mol / L, stir at a temperature of 77°C for 1.3h, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com