Manufacturing method of glass cup with antibiosis and cold and hot impact resistance

A manufacturing method and technology for glass cups, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve problems such as easy cracking, easy peeling of coatings, and difficult handling of glass cups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

[0030] A method for manufacturing a glass cup with antibacterial and thermal shock resistance, comprising the steps of:

[0031] 1) Preparation of liner heat insulating agent: silver nitrate, potassium chloride, aluminum oxide, sodium silicate or mixed with each other;

[0032] 2) Coating heat-insulating agent on the inner tank: after three coatings and three drying steps, first coat silver nitrate on the inner tank of the cup and dry; then coat potassium chloride and dry; finally coat sodium silicate mixture and dry;

[0033] 3) Firing of the cup body: Put the cup shell and liner on the rolling machine and burn it into a double-layer semi-finished high borosilicate glass cup for use;

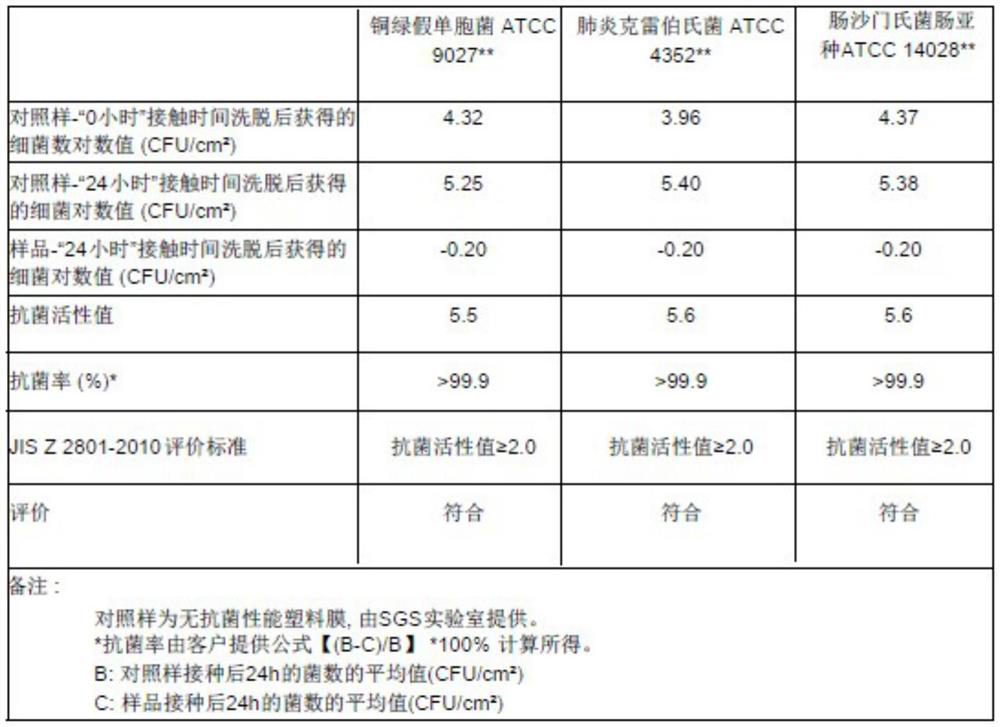

[0034] 4), selection and preparation of antibacterial agent salt: the salt is one or more of sulfates, nitrates, chlorides, carbonates and hydroxides containing alkali m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com