Concrete mineral admixture capable of improving chloride ion penetration resistance and concrete

A technology of mineral admixture and chloride ion penetration, which is applied in the field of concrete mineral admixture and concrete to achieve the effects of increasing resistance, significant economic value and environmental value, and utilization and protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a kind of concrete mineral admixture that improves anti-chloride ion penetration ability, and described concrete mineral admixture comprises calcined kaolin tailings 63%, limestone powder 32%, gypsum 2.69%, slaked lime 2%, according to weight percentage, Modified starch 0.01% and Glauber's salt 0.3%.

[0027] After uniform mixing in a mixer, the concrete mineral admixture L1 is obtained.

[0028] In this example, the preparation method of the calcined kaolin tailings is: calcining the kaolin tailings completely at 750-850°C, after cooling, adding a grinding aid accounting for 0.05-0.2% of the tailings mass fraction, and grinding them into calcined kaolin Tailings powder, specific surface area greater than 500m 2 / kg. When grinding, the grinding aid and absolute ethanol are diluted into a solution according to the volume ratio of 1:3-1:1, and the grinding time is 20-40min. The grinding aid is alkanolamine series. In the present embodiment, de...

Embodiment 2

[0030] This embodiment is roughly the same as Embodiment 1, except that the concrete mineral admixture includes 50% of calcined kaolin tailings, 45% of limestone powder, 4.38% of gypsum, 0.5% of slaked lime, and 0.02% of modified starch according to the percentage by weight. % and thenardite 0.1%.

[0031] The concrete mineral admixture L2 is obtained after being uniformly mixed in a mixer.

Embodiment 3

[0033] This embodiment is roughly the same as Embodiment 1, except that the concrete mineral admixture includes 65% of calcined kaolin tailings, 25% of limestone powder, 4.49% of gypsum, 5% of slaked lime, and 0.01% of modified starch according to the percentage by weight. % and thenardite 0.5%.

[0034] The concrete mineral admixture L3 is obtained after being uniformly mixed in a mixer.

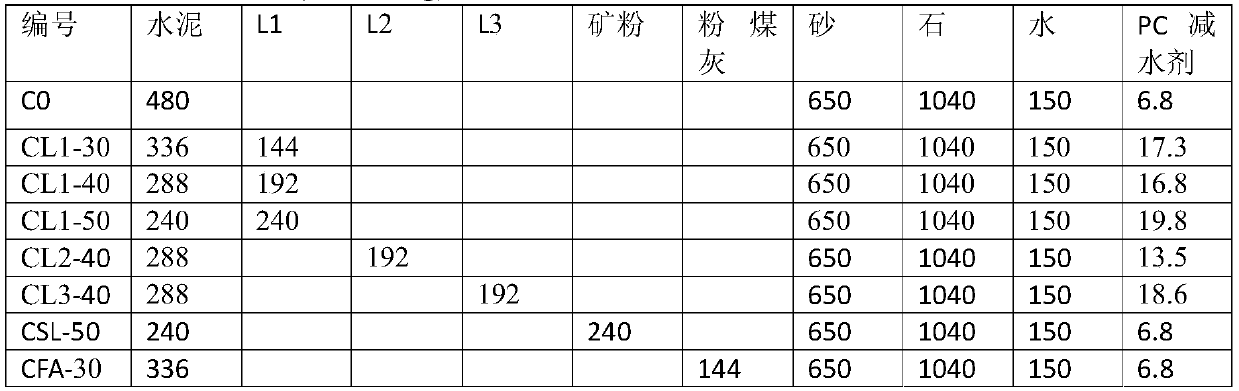

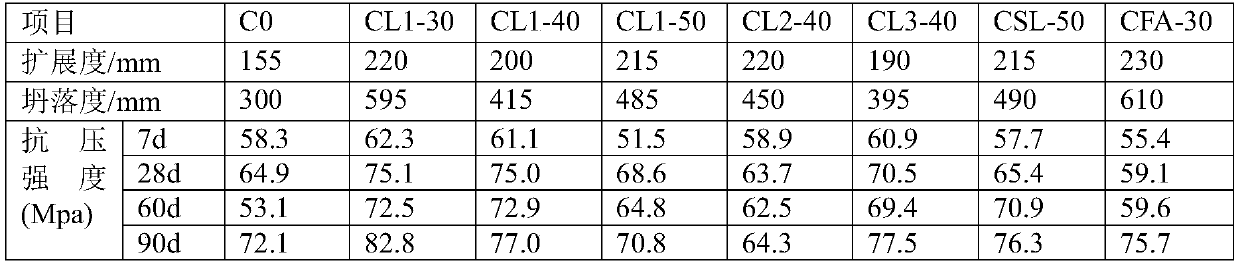

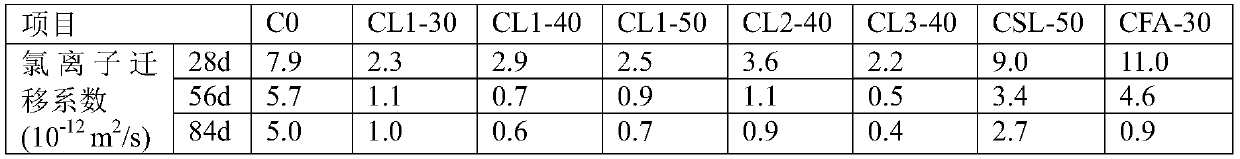

[0035] The raw materials used to configure concrete are cement, the above-mentioned mineral admixtures L1 to L3, and fly ash and mineral powder used as comparison. The fine aggregate is river sand with a modulus of 2.5, the coarse aggregate is 5-25mm continuous graded gravel, and the water is tap water. The specific mixing ratio is listed in Table 1. The water reducer used is a polycarboxylate high-efficiency water reducer with a solid content of 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com