Biomass three-dimensional porous graphene and preparation method thereof

A three-dimensional porous, biomass technology, applied in graphene, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of environmental pollution, difficulty in mass production, long preparation cycle, etc. The effect of reducing production cost and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing biomass three-dimensional porous graphene, comprising the following steps:

[0039] (1) Drying the biomass material and pulverizing it to obtain biomass powder for subsequent use;

[0040] (2) Grinding and mixing the biomass powder and water-soluble inorganic salt obtained in (1) evenly in a mass ratio of 1:4-10, performing high-temperature cracking reaction in an inert gas atmosphere, and then cooling down to room temperature;

[0041] (3) Wash away the inorganic salt template with hot water at 90-100° C., and recover the molten salt through filtration and washing. Meanwhile, the obtained black solid product is dried to obtain biomass three-dimensional graphene.

[0042] Specifically, the biomass material includes agricultural and forestry resources and wastes, and the agricultural and forestry resources and wastes in the present invention include at least one of rice husks, corn cobs, corn stalks, peanut shells, walnut she...

Embodiment 1

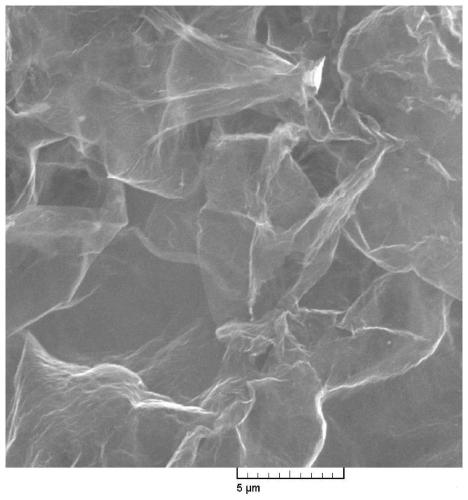

[0048] Take corncobs and dry them at 120°C for 12 hours, then crush them to below 60 mesh with a pulverizer to obtain corncob powder, take 1.0g corncob powder and 5.0g Na 2 CO 3 Mix and grind evenly, place in a corundum crucible, place in a tube-type atmosphere furnace, and under the protection of Ar gas, raise from room temperature to 900°C at 5°C / min, keep the temperature at 900°C for 10min, then cool down to room temperature, and use Hot water (90-100°C) washes away the inorganic salt template, filters and washes to recover the molten salt, and at the same time, the obtained black solid product is dried to obtain biomass three-dimensional graphene. In this example, Na 2 CO 3 The structure of three-dimensional graphene prepared from molten salt and corn cob as carbon source is as follows figure 1 shown.

Embodiment 2

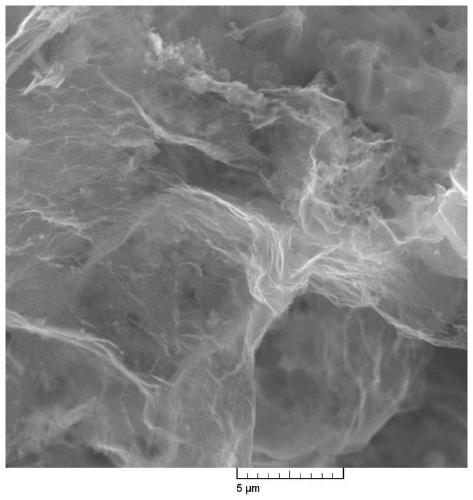

[0050] Take corncobs and dry them at 120°C for 12 hours, then crush them to below 60 mesh with a pulverizer to obtain corncob powder, take 1.0g corncob powder and 5.0g K 2 CO3 Mix and grind evenly, place in a corundum crucible, place in a tube-type atmosphere furnace, and under the protection of Ar gas, raise from room temperature to 900°C at 5°C / min, keep the temperature at 900°C for 10min, then cool down to room temperature, and use Hot water (90-100°C) washes away the inorganic salt template, and the molten salt is recovered by filtration and washing, and the black solid product obtained at the same time is dried to obtain biomass three-dimensional graphene, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com