Preparation method of tunneling oxidation passivation battery

A tunneling and battery technology, applied in the field of solar photovoltaic, can solve the problems of long process flow and poor appearance, and achieve the effect of simplifying the process, improving passivation performance and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

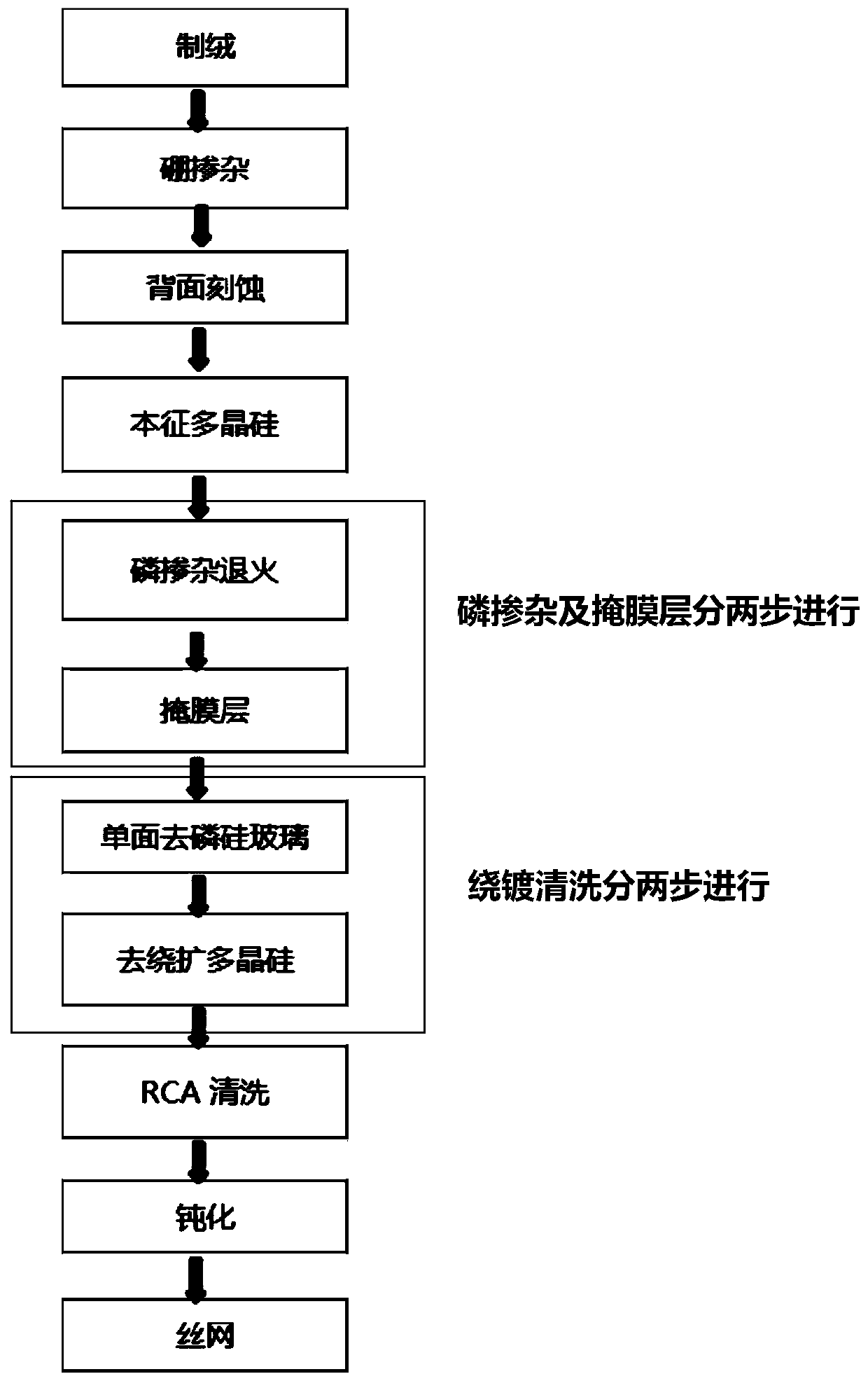

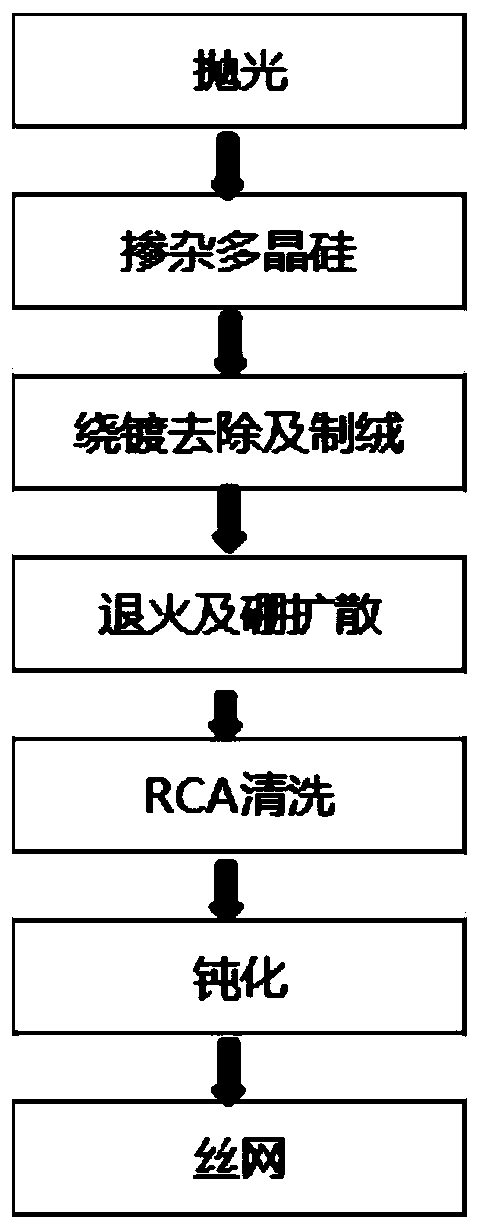

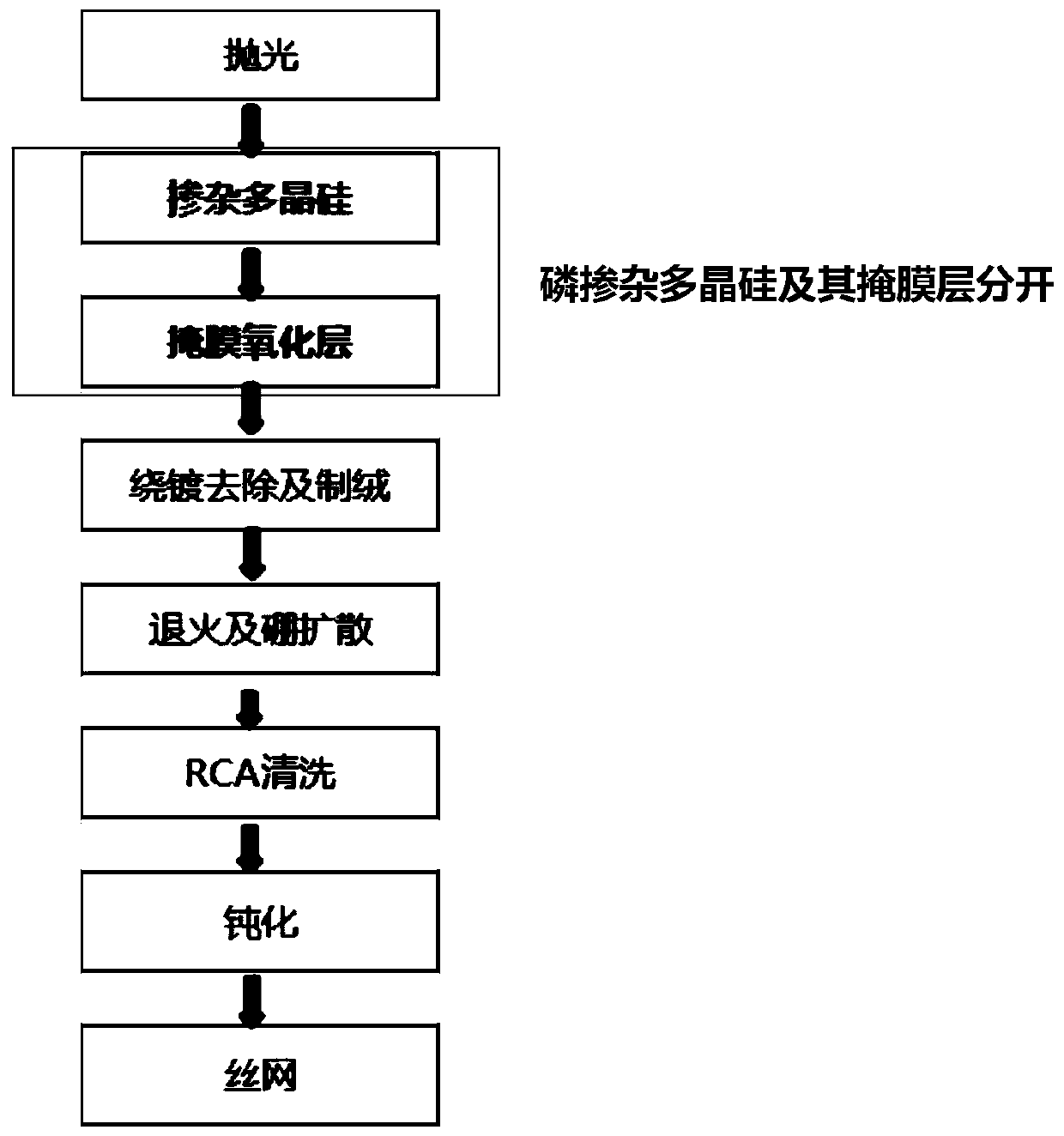

[0035] The preparation process steps of a novel tunneling oxidation passivation battery are as follows:

[0036] (1) Polishing—Using N-type silicon wafers as the substrate, using a slot machine KOH: polishing additive: H 2 O=2:1:15 (volume ratio) (polishing additive is composed as follows according to the mass fraction: 4 parts of sodium benzoate, 7 parts of surfactant (sodium hydroxide: alkylphenol polyoxyethylene ether=1:2 (mass ratio)), 11 parts of palmitic acid, 3 parts of polyethylene glycol, 2 parts of alkyl polyglucoside and 73 parts of deionized water), the temperature is controlled at 75°C, the polishing time is 6min, the weight loss is 0.7g, and the reflectivity is controlled at 38%;

[0037] (2) Doped polysilicon—in the LPCVD furnace tube, the silicon oxide deposition temperature is maintained at 610°C, O 2 (Oxygen) 2L, time 20min, thickness 1.4nm; followed by intrinsic polysilicon deposition, deposition temperature 620°C, SiH 4 (Silane) flow rate 500sccm, time 2...

Embodiment 2

[0045] (1) Polishing - using N-type silicon wafer as the substrate, using NaOH: polishing additive: H 2 O=3:2:15 (volume ratio) chain polishing (polishing additive is composed as follows according to the mass fraction: 5 parts of sodium benzoate, 5 parts of surfactant (sodium hydroxide: alkylphenol polyoxyethylene ether=1: 1.5 (mass ratio)), 7 parts of palmitic acid, 3 parts of polyethylene glycol, 5 parts of alkyl polyglucoside and 75 parts of deionized water), the temperature is controlled at 80°C, the polishing time is 3min, the weight loss is 0.4g, and the reflection The rate is controlled at 39%;

[0046] (2) Doped polysilicon—in the LPCVD furnace tube, the silicon oxide deposition temperature is maintained at 620°C, O 2 (Oxygen) 1.5L, time 15min, thickness 1.6nm; followed by intrinsic polysilicon deposition, deposition temperature 610°C, SiH 4 (Silane) flow rate 550sccm, time 2min; repass SiH 4 450sccm, pH of 5% mass concentration 3 40sccm, time 40min, doped polysil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com