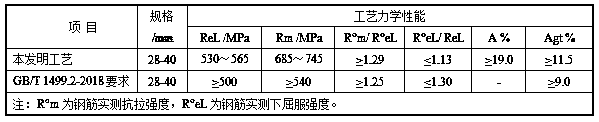

Vanadium-chromium microalloying large-specification 500MPa ultra-fine grain corrosion-resisting anti-seismic steel bar and preparation method thereof

A technology of micro-alloying and anti-seismic steel bars, which is applied in the field of metallurgy, can solve the problems of reducing product market competitiveness, high price of vanadium alloys, unfavorable production costs, etc., to improve anti-seismic performance, improve precipitation strengthening effect, and promote tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

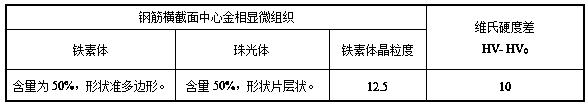

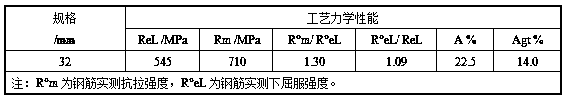

Examples

preparation example Construction

[0021] The method for preparing vanadium-chromium microalloyed large-size 500MPa ultra-fine-grain corrosion-resistant and shock-resistant steel bar of the present invention includes molten steel smelting, deoxidation alloying, LF furnace refining, casting, billet heating, and controlled rolling and controlled cooling, specifically including the following steps :

[0022] a. Molten steel smelting: scrap steel, pig iron and molten iron at 160-180kg / t respectively 钢 , 30~40kg / t 钢 , 850~880kg / t 钢 Ratio, add LD converter, then carry out conventional top-bottom compound blowing, add conventional lime, light-burned dolomite, magnesite ball slag, lime addition is 20-25kg / t 钢 , the amount of lightly burned dolomite added is 15-18kg / t 钢 , the addition of magnesite balls is 0.5kg / t 钢 , the carbon content at the control end point is ≥0.07wt%, the tapping temperature is ≤1625°C; the ladle before tapping is 4.0kg / t 钢 The amount of vanadium-containing pig iron in the following mass rati...

Embodiment 1

[0042] a. Molten steel smelting: 160kg / t respectively 钢 、30kg / t 钢 The cold material is charged into the proportion, and the scrap steel (chemical composition: C 0.20wt%, Si 0.35wt%, Mn 1.25wt%, P 0.032wt%, S 0.028wt% is added in the LD converter, and the rest is Fe and Inevitable impurities) and pig iron (chemical composition: C 3.2wt%, Si 0.20wt%, Mn 0.40wt%, P0.080wt%, S 0.020wt%, the rest is Fe and unavoidable impurities); Then press 880kg / t 钢The proportion of molten iron is loaded into the LD converter with the following temperature and mass ratio of molten iron: molten iron temperature 1290 ° C, molten iron composition C 4.2wt%, Si0.25wt%, Mn 0.40wt%, P 0.085wt%, S 0.025wt% , the rest is Fe and unavoidable impurities; scrap steel, pig iron and molten iron are blended into the LD converter, then conventional top-bottom composite blowing is carried out, and conventional lime, lightly burned dolomite and magnesite balls are added to make slag, and the amount of lime added ...

Embodiment 2

[0056] a. Molten steel smelting: 170kg / t respectively 钢 、40kg / t 钢 The cold material is loaded into the proportion, and the scrap steel (chemical composition: C 0.22wt%, Si 0.48wt%, Mn 1.32wt%, P 0.040wt%, S 0.039wt% is added to the LD converter with the following mass ratio, and the rest is Fe and Inevitable impurities) and pig iron (chemical composition: C 3.3wt%, Si 0.30wt%, Mn 0.50wt%, P0.090wt%, S 0.029wt%, the rest is Fe and unavoidable impurities); Then press 870kg / t 钢 The proportion of molten iron is loaded into the LD converter with the following temperature and mass ratio of molten iron: molten iron temperature 1300 ° C, molten iron composition C 4.4wt%, Si0.35wt%, Mn 0.55wt%, P 0.095wt%, S 0.035wt% , the rest is Fe and unavoidable impurities; scrap steel, pig iron and molten iron are blended into the LD converter, then conventional top-bottom composite blowing is carried out, and conventional lime, lightly burned dolomite and magnesite balls are added to make slag,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com