LCP packaging substrate with built-in passive resistance-capacitance element and manufacturing method

A technology for packaging substrates and resistance-capacitance components, which is applied to electrical components, resistors, capacitors, etc., which can solve the problem of large influence of process material limitations, resistance and capacitance accuracy, and LCP surface quality. problems, to achieve the effect of improving circuit performance, increasing surface utilization, and reducing the difference in resistance or capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

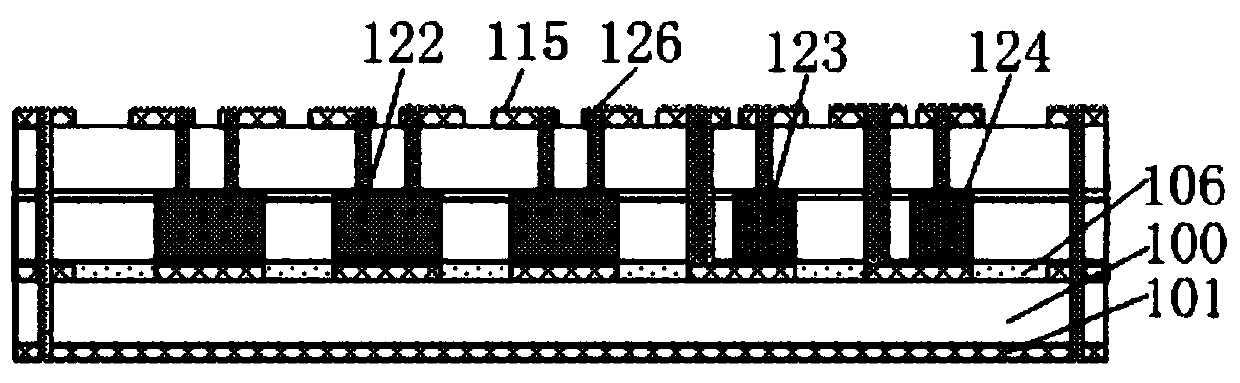

[0072] like figure 1 and Figures 4a to 4d As shown in , the present invention discloses an LCP package substrate with embedded passive resistance-capacitance elements, comprising:

[0073] Thin film resistance and capacitance, including thin film resistor 122 and thin film capacitor 123, two electrodes of the thin film resistor 122 are electroplated copper posts, and the upper electrode of the thin film capacitor 123 is electroplated copper posts;

[0074] The bottom plate of the LCP substrate includes a thin film RC embedded region 104 and a first LCP substrate positioning through hole 105;

[0075] At least one LCP substrate transition piece, including a first thin film resistor embedded frame 106, a first thin film capacitor embedded frame 107, a first thin film capacitor lower electrode lead-out through hole 108 and a second LCP substrate positioning through hole 109;

[0076] At least two LCP substrate bonding sheets, including a second thin film resistor embedded fram...

Embodiment 2

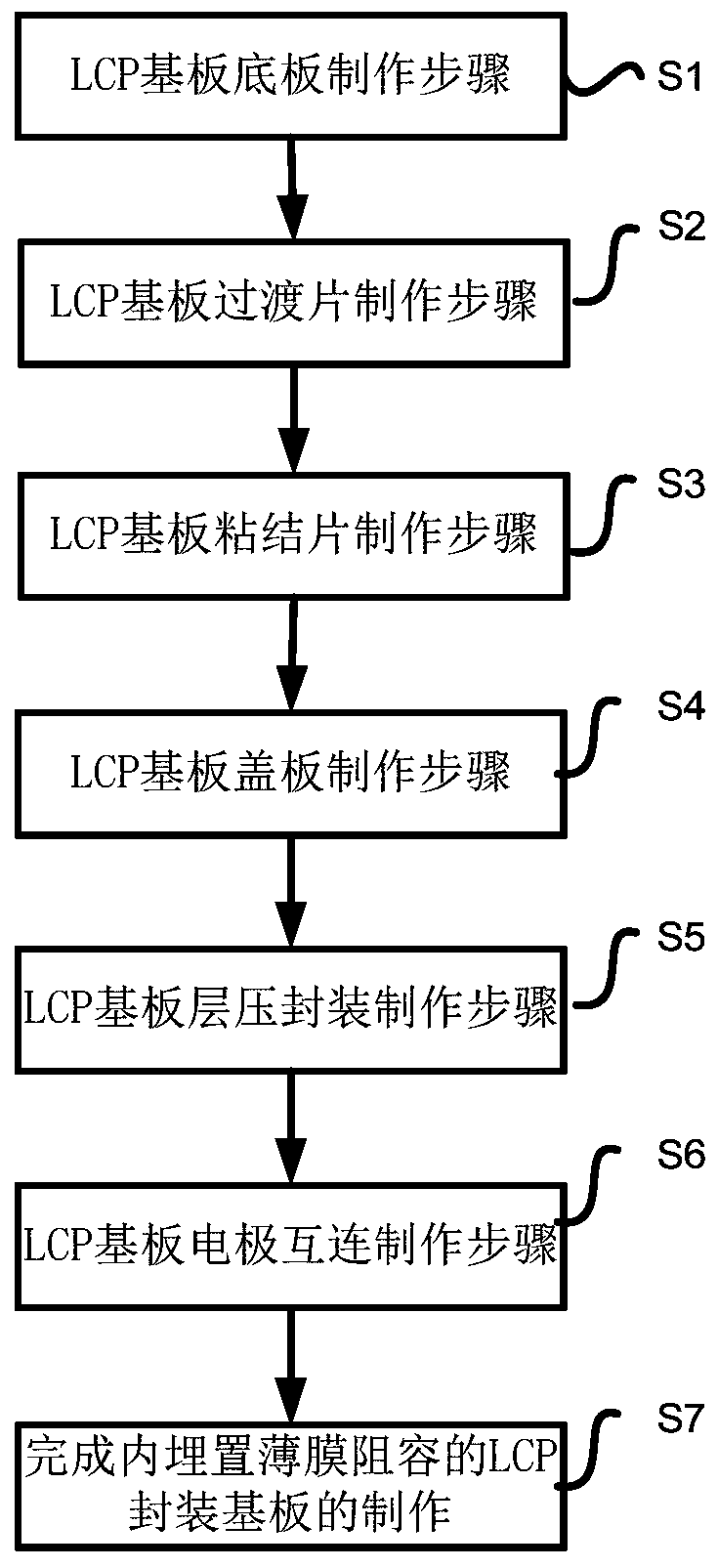

[0084] like figure 2 and 3a As shown in ~31, the present invention further discloses a method for manufacturing an LCP package substrate with embedded thin film resistance and capacitance, using the above-mentioned LCP package substrate with embedded thin film resistance and capacitance for manufacturing, including the following steps:

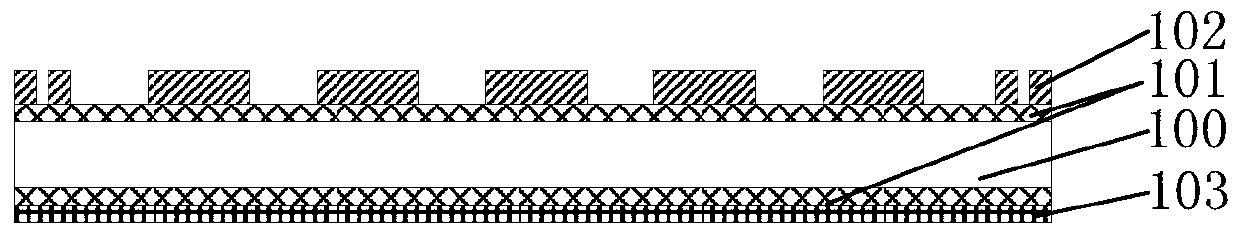

[0085] Step A: The LCP substrate bottom plate fabrication step, providing an LCP substrate 100 with a double-sided copper clad layer 101 , the back of the substrate is covered with a copper-clad tape 103 for protection, and the front of the substrate is subjected to photoresist 102 lithography, pattern electroplating Cu / Ni / Au, wet etching, forming a thin film resistance-capacitance buried area 104 on the front side of the substrate, removing the adhesive tape 103 on the back side, and then processing the first LCP substrate positioning through hole 105 by ultraviolet laser to form the LCP substrate bottom plate;

[0086] Step B: the LCP sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com