A kind of molybdenum disulfide catalyst rich in defect 1t-2h mixed phase and its preparation method and application

A 1T-2H, molybdenum disulfide technology, used in the synthesis of materials and catalytic applications, to achieve high stability, avoid high-temperature roasting, and high hydrodesulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

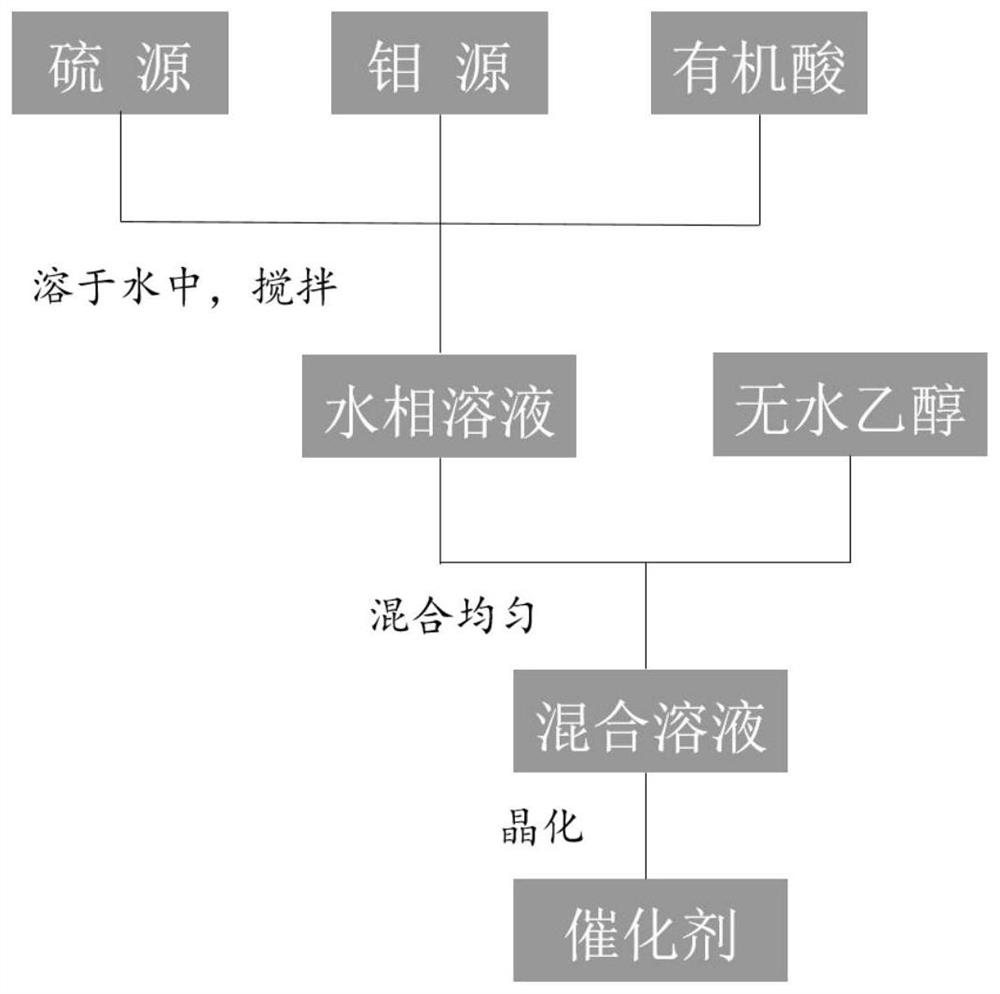

[0041] Take thiourea (4g), ammonium heptamolybdate tetrahydrate (0.989g) and anhydrous oxalic acid (0.504g) and dissolve in 40ml of ultrapure water, stir until dissolving to obtain the first mixture, wherein the concentration of molybdenum is 0.14mol / L, the molar ratio of sulfur to molybdenum is 9:1, and the molar ratio of anhydrous oxalic acid to molybdenum is 1:1. Add 40ml of ethanol, stir well at room temperature, and mix well to obtain the second mixture, wherein the volume ratio of water in the first mixture to ethanol in the second mixture is 1:1. Then move it into a crystallization kettle for crystallization, the crystallization temperature is 200°C, and the crystallization time is 12h. After crystallization, the supernatant was removed by filtration, washed alternately with deionized water and ethanol four times, and the precipitate was fully dried at 60°C under vacuum for 12 hours to obtain MoS 2 catalyst.

Embodiment 2

[0043] On the basis of Example 1, the addition of ethanol is 60ml, the addition of water is 20ml, the volume ratio of water and ethanol is 1:3, and the rest of the preparation steps are the same as in Example 1.

Embodiment 3

[0045] On the basis of Example 1, the amount of ethanol added is 20ml, the amount of water added is 60ml, the volume ratio of water to ethanol is 3:1, and the rest of the preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com