Preparation method of N-doped Cu-modified nickel-based activated carbon catalyst and application of N-doped Cu-modified nickel-based activated carbon catalyst in nitrocyclohexane hydrogenation reaction

A technology of nitrocyclohexane and activated carbon, applied in catalyst activation/preparation, catalyst, carbon compound catalyst and other directions, can solve the problems of high cost, high requirements, environmental pollution, etc., achieves less environmental pollution, improved conversion rate, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

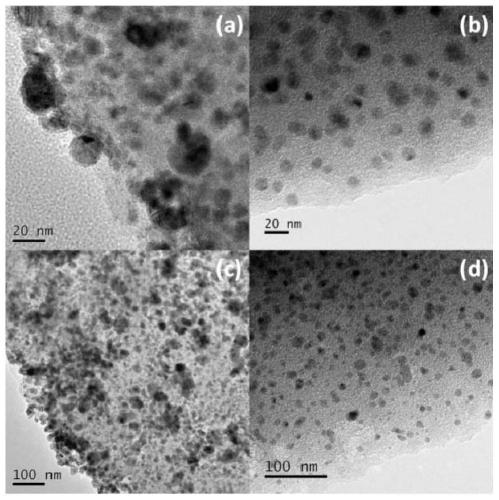

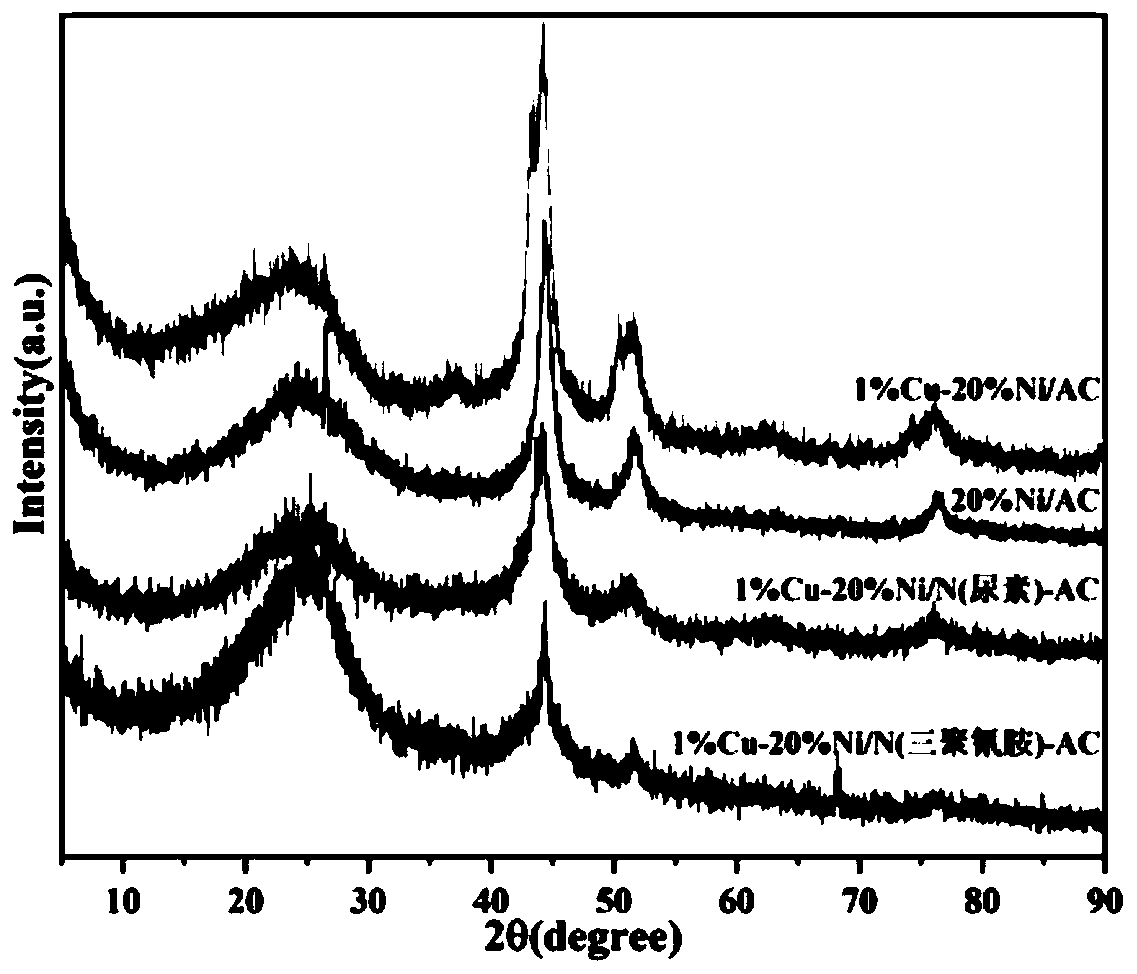

[0028] Weigh 20g of commercial activated carbon, place it in a single-necked flask, add concentrated nitric acid according to the solid-to-liquid mass ratio of 1:20, stir and soak at room temperature for 24h, filter the suspension, wash with distilled water until neutral, and dry at 80°C for 12h to obtain Modified activated carbon. Take by weighing 1 g of the above-mentioned modified activated carbon and 1 g of melamine and place them in a single-necked flask, weigh 0.85 g of Ni(CH 3 COO) 2 4H 2 O, 0.04gCu(NO 3 ) 2 ·3H 2 O, after dissolving with 30g of deionized water, the resulting solution was added to a one-necked flask equipped with activated carbon, and a magnet was added, and stirred and impregnated at 30°C for 24h. Put the stirred suspension in a beaker and dry it in a drying oven at 80°C for 12 hours. Grind the dried solid into powder with an agate mortar, put it into a tube furnace for roasting and reduction, and protect the first stage under nitrogen. Heat up a...

Embodiment 2

[0030] Weigh 0.12g of the 1%Cu-20%Ni / N(melamine)-AC catalyst gained in Example 1 and place it in a 50mL liner of a high-temperature reactor, add 0.5g of nitrocyclohexane, 5.2g of ethylenediamine, and put Insert the magnet, seal the autoclave, replace the air in the autoclave with hydrogen for 4 times, evacuate the autoclave to a vacuum with a vacuum pump, and then place the autoclave in a heating jacket. After rising to the set reaction temperature of 100°C, hydrogen gas was introduced to pressurize to 0.3MPa, magnetic stirring was started, and the reaction timing started. After reacting for 8 hours, the reaction mixture was filtered, and the content of each substance in the filtrate was analyzed by gas chromatography. The conversion rate of nitrocyclohexane is 99.46%, and the selectivity of cyclohexanone oxime is 86.59%.

Embodiment 3

[0032] Weigh 0.12g of the 1%Cu-20%Ni / N(melamine)-AC catalyst gained in Example 1 and place it in a 50mL liner of a high-temperature reactor, add 0.5g of nitrocyclohexane, 5.2g of ethylenediamine, and put Insert the magnet, seal the autoclave, replace the air in the autoclave with hydrogen for 4 times, evacuate the autoclave to a vacuum with a vacuum pump, and then place the autoclave in a heating jacket. After rising to the set reaction temperature of 80°C, hydrogen gas was introduced to pressurize to 0.3 MPa, magnetic stirring was started, and the reaction timing started. After reacting for 8 hours, the reaction mixture was filtered, and the content of each substance in the filtrate was analyzed by gas chromatography. The conversion rate of nitrocyclohexane is 83.62%, and the selectivity of cyclohexanone oxime is 78.81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com