Conductive silver paste for filter and preparation method and sintering method thereof

A conductive silver paste and filter technology, which is applied in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve poor adhesion, not suitable for 5G ceramic base filters, conductive silver Solve problems such as poor Q value of paste, achieve good compactness, good silver layer dense adhesion, and good leveling advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

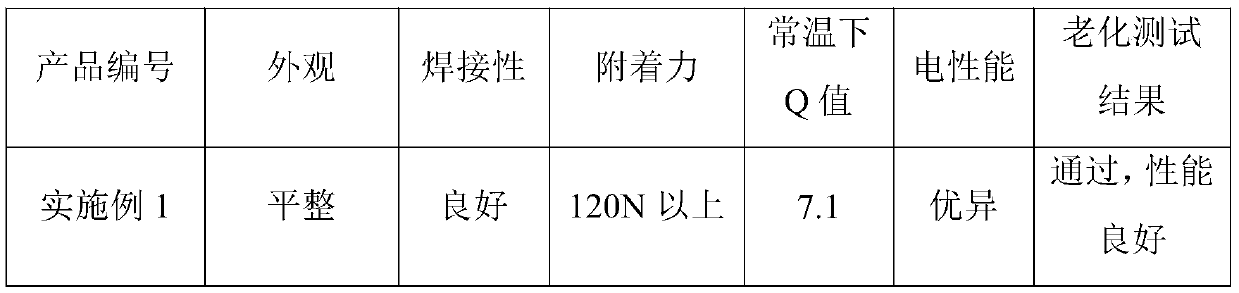

Embodiment 1

[0029] Embodiment 1: (does not contain platinum group metal oxide)

[0030] A preparation method of conductive silver paste for filter:

[0031] (1) By mass percentage, weigh 1% of ethyl cellulose STD~200, 9% of polymethacrylic resin BM90, 10% of diethylene glycol butyl ether, 15% of alcohol ester twelve, 50% of diethylene glycol ethyl ether acetate, 10% tributyl citrate, 5% Span 85, heating and stirring at 50-100° C. to obtain an organic vehicle.

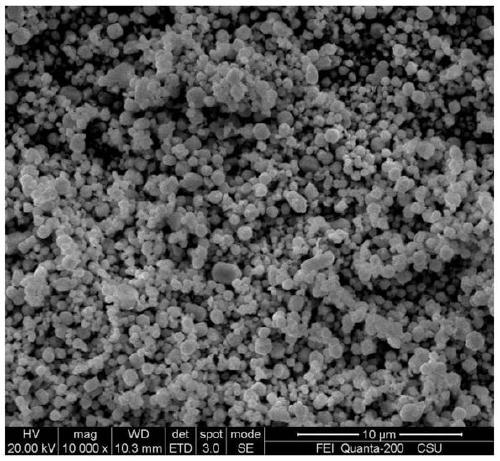

[0032] (2) Weigh 5g of Bi-Si-Cu-B-Li-Sn-O system glass powder, 35g of organic carrier prepared in step (1), 48g of main silver powder, 12g of auxiliary silver powder; wherein, the main silver powder is round The spherical silver powder has a particle size distribution of 0.3 μm for D10, 0.8 μm for D50, and 2.0 μm for D90; the auxiliary silver powder is flake silver powder, and the particle size distribution is 0.3 μm for D10, 1 μm for D50, and 3.5 μm for D90; the glass The average particle size of the powder was 1 μm.

[0033] (...

Embodiment 2

[0034] Embodiment 2: (containing platinum group metal oxide)

[0035] (1) By mass percentage, take by weight 2% ABS resin, 3% phenolic resin 2402, 20% alcohol ester hexadecane, 45% diethylene glycol butyl ether acetate, 10% tributyl citrate , 5% terpineol, 10% Span 85, 5% lecithin, heated and stirred at 50-100° C. to obtain an organic vehicle.

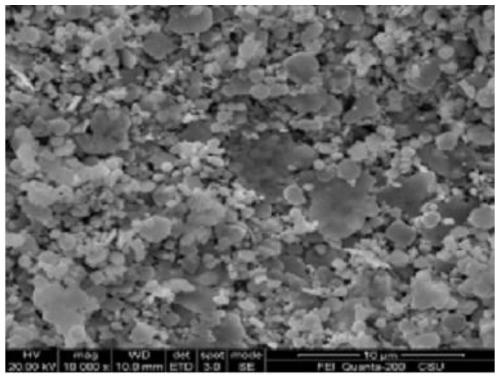

[0036](2) Weigh 1g of Bi-Si-Cu-B-Li-Sn-O system glass powder, 8.9g of organic carrier prepared in step (1), 0.1g of palladium oxide, 88g of main silver powder, and 2g of auxiliary silver powder; wherein, The main silver powder is spherical silver powder, and the particle size distribution is 0.35 μm for D10, 1.0 μm for D50, and 2.2 μm for D90; the auxiliary silver powder is flake silver powder, and the particle size distribution is 0.35 μm for D10, 0.8 μm for D50, and The average particle size of the glass powder is 2 μm; the average particle size of palladium oxide is 1.5 μm.

[0037] (3) Add the above-mentioned materials into a fas...

Embodiment 3

[0038] Embodiment 3: (containing platinum group metal oxide)

[0039] (1) by mass percentage, take by weighing 4% polyester resin, 4% hydrogenated rosin resin, 10% alcohol ester twelve, 60% diethylene glycol ethyl ether acetate, 10% tributyl citrate , 10% DBE, 2% Span 85, heated and stirred at 50-100°C to obtain an organic vehicle;

[0040] (2) Take by weighing 5g of Bi-Si-Cu-B-Li-Sn-O system glass powder, 14g of organic carrier prepared in step (1), 2g of platinum oxide, 1g of ruthenium oxide, 70g of main silver powder, and 8g of auxiliary silver powder; Wherein, the main silver powder is a spherical silver powder, and the particle size distribution is 0.35 μm for D10, 2.2 μm for D50, and 3.0 μm for D90; the auxiliary silver powder is flake silver powder, and the particle size distribution is 0.4 μm for D10, and 1.5 μm for D50. , D90 is 4.0 μm, the average particle size of the glass powder is 3 μm; the average particle size of platinum oxide is 2.0 μm; the average particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com