Graphene-based ultra-black extinction coating and preparation method thereof

A technology of graphene and matting coatings, which is applied in coatings, epoxy resin coatings, reflection/signal coatings, etc., can solve the problems of unsatisfactory visible-infrared light absorption, poor aging resistance, and high substrate selectivity. Achieve the effects of improving the performance of eliminating stray light, reducing reflectivity, and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention at first provides a kind of preparation method based on graphene ultra-black matting coating, and this method comprises the following steps:

[0026] (1) Configure component B first, according to the following ratio:

[0027] Thinner 5.0~97.0 parts

[0028] Crosslinking agent 10.0~30.0 parts

[0029] Catalyst 1.0~10.0 parts

[0030] (2) Since the black filler in component A is easy to deposit, generally choose the method of on-site deployment and fully stirring in the mixer before adding the corresponding component B. Component A is added in the following proportion and order:

[0031]

[0032]

[0033] (3) Mix the solution prepared in step (1) and step (2) uniformly according to A:B=3~8:1 (weight ratio) during use, and the mixing time is about 0.5-3h, then filter and separate For equipment.

Embodiment 1

[0035] Add 70.0 parts of ethyl acetate, 25.0 parts of methyltriethoxysilane, and 5.0 parts of dibutyltin laurate into the container at room temperature, mix well and stir evenly, and record this solution as component B solution. In addition, the component A solution is prepared at room temperature, and the substances added and the corresponding order are as follows: 8 parts of a mixture of graphene and carbon powder, 10 parts of silicone resin, 50 parts of ethyl acetate, and 15 parts of methyltriethoxysilane , 8 parts of γ-methacryloxypropyltrimethoxysilane (KH-570), 9 parts of isopropanol. In a high-speed sand mill, stir the solution of component A at a speed of 1440r / min for 30 minutes, then mix the components A and B at a ratio of 5:1, and after stirring evenly, filter it with 300-mesh nylon gauze, that is, A uniformly dispersed black nano matte paint is obtained.

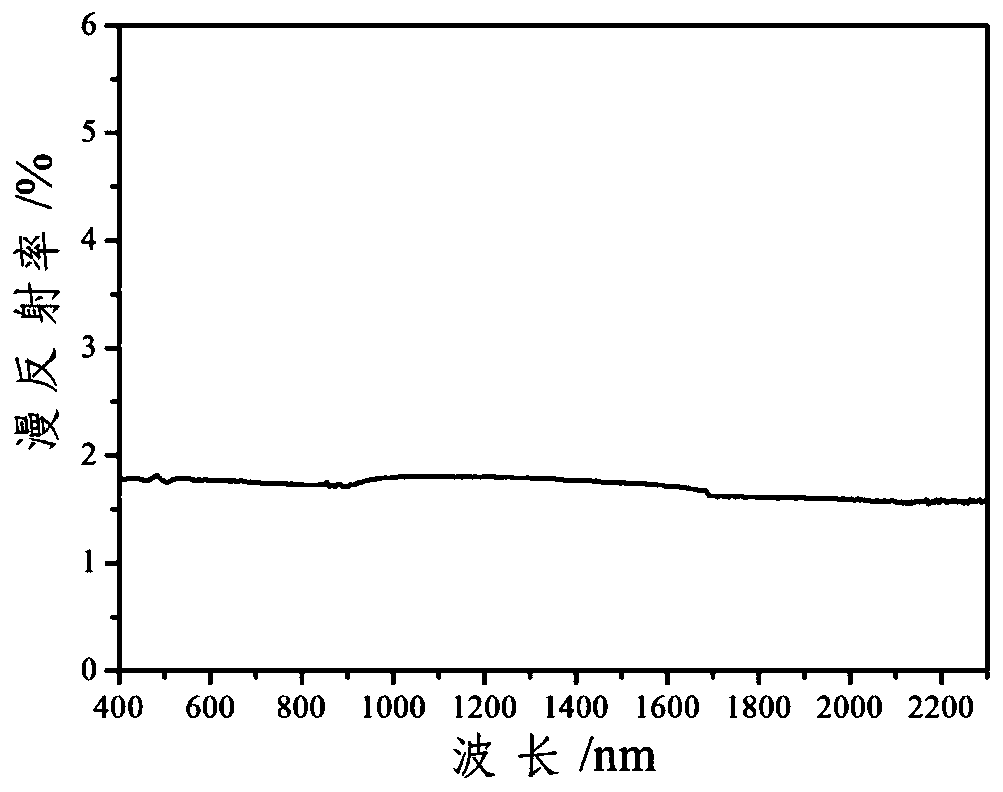

[0036] The material is coated on an aluminum alloy plate by spraying, and it is completely cured for 5 days ...

Embodiment 2

[0038] Add 70.0 parts of ethyl acetate, 25.0 parts of methyltriethoxysilane, and 5.0 parts of dibutyltin laurate into the container at room temperature, mix well and stir evenly, and record this solution as component B solution. In addition, the component A solution is prepared at room temperature, and the substances added and the corresponding order are as follows: 8 parts of a mixture of graphene and carbon powder, 10 parts of silicone resin, 50 parts of ethyl acetate, and 15 parts of methyltriethoxysilane , 8 parts of γ-methacryloxypropyltrimethoxysilane (KH-570), 9 parts of isopropanol. In a high-speed sand mill, stir the solution of component A at a speed of 1440r / min for 30 minutes, then mix the components A and B at a ratio of 5:1, and after stirring evenly, filter it with 300-mesh nylon gauze, that is, A uniformly dispersed black nano matte paint is obtained.

[0039] Apply the paint with a brush to the aluminum alloy plate by brushing, and completely cure it for 5 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com