Pipe straightening control system and method and application of pipe straightening control method to titanium alloy pipe straightening

A control method and control system technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problem that titanium alloy special-shaped pipes cannot be straightened, and achieve the elimination of work hardening and residual stress, excellent mechanical properties, and effects. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

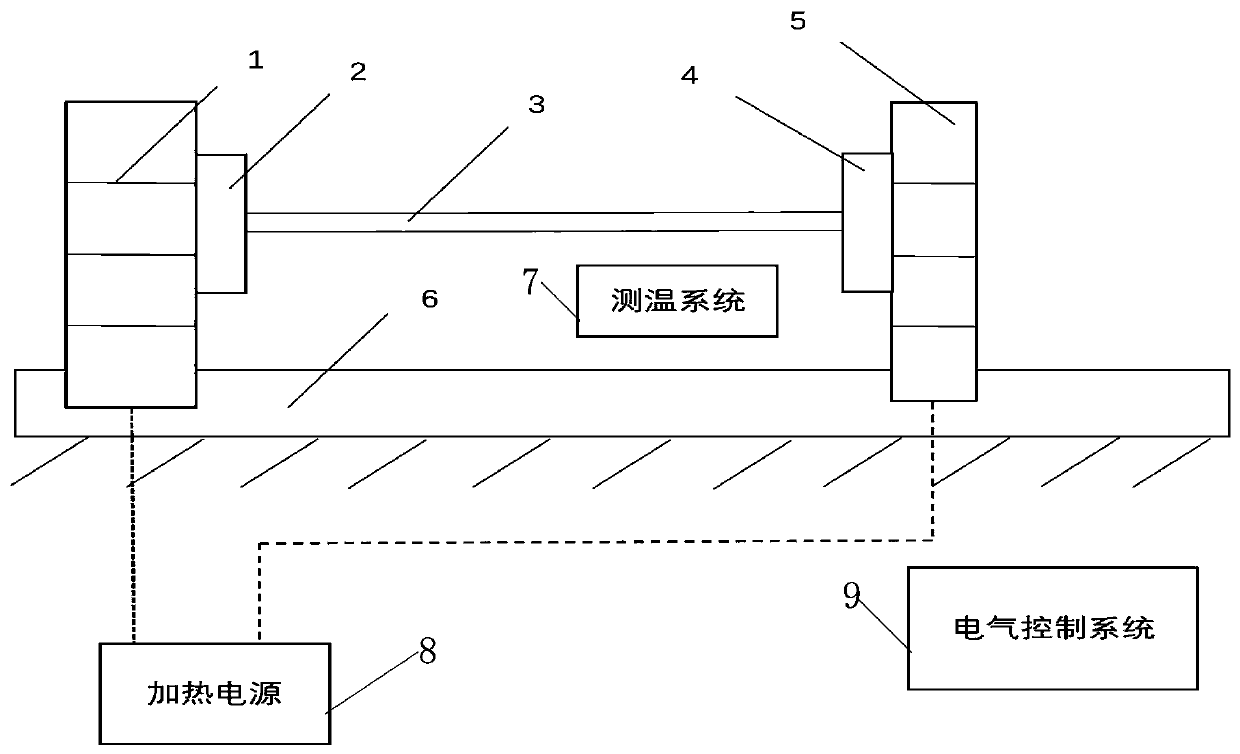

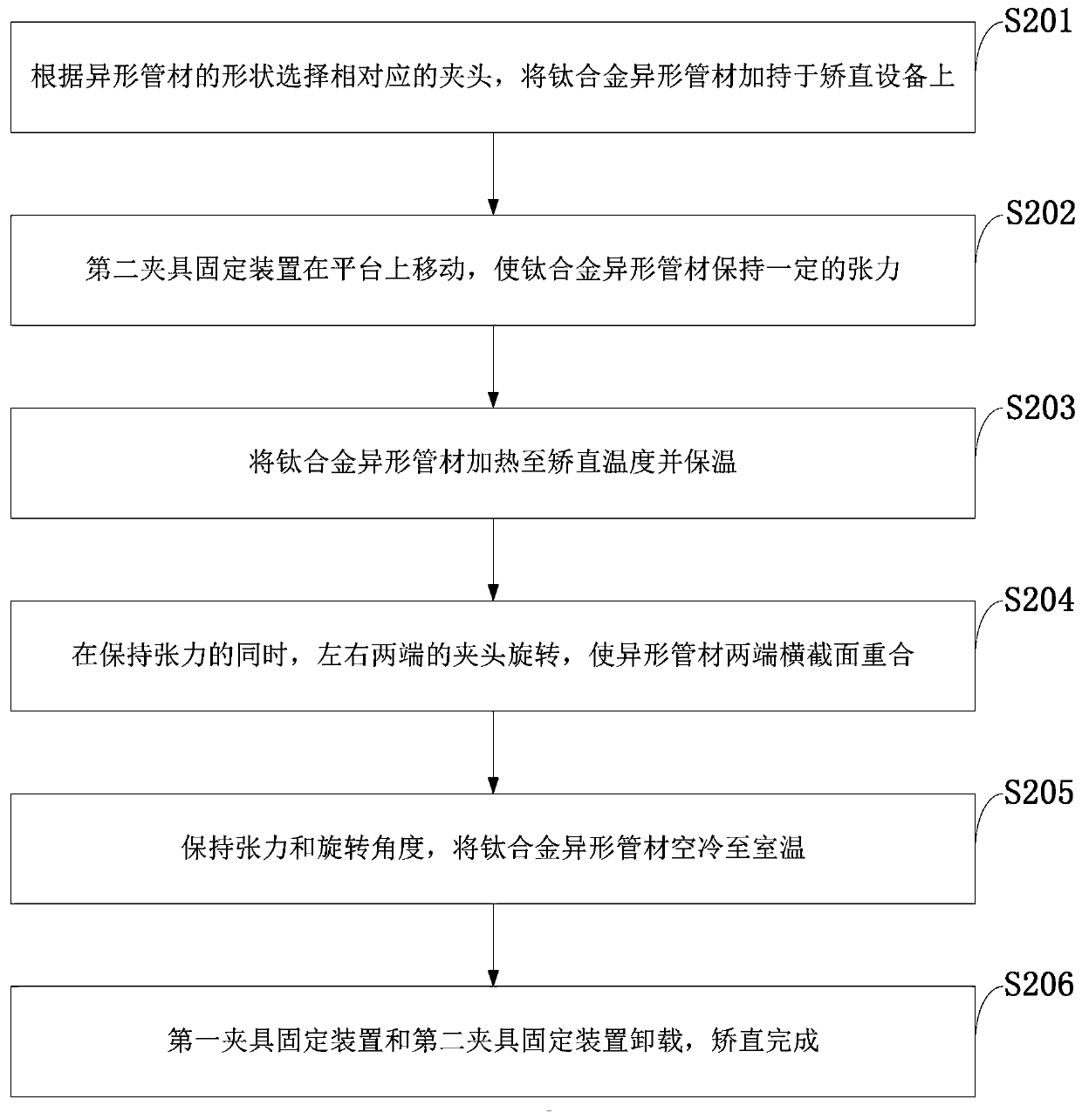

[0047] TC4 titanium alloy 50 * 50mm provided by the invention, wall thickness 3.5mm, the seamless square tube of length 3000mm, straightening method comprises the following steps:

[0048] (1) Select a square fixture and fix the two ends of the 3000mm long titanium alloy square pipe on the straightening equipment.

[0049] (2) The left clamp is fixed, and the right clamp fixture starts to move along the axis direction to ensure that the two ends of the square tube are tightened.

[0050] (3) Turn on the power and start heating. When the infrared temperature measurement system feeds back that the temperature of the square tube body reaches 700°C, keep it warm for 5 minutes.

[0051] (4) While maintaining the tension, the left and right clamps start to rotate along the normal direction of the section, so that the sections at both ends of the square tube overlap as much as possible.

[0052] (5) Turn off the power, and air-cool the titanium alloy square tube to room temperature. ...

Embodiment 2

[0056] The TA18 titanium alloy oval pipe 40 * 60mm that the present invention provides, wall thickness 4mm, the seamless pipe material of length 2000mm, straightening method comprises the following steps:

[0057] (1) Select the oval clamp, and fix the two ends of the 2000mm long titanium alloy oval pipe on the straightening equipment.

[0058] (2) The left clamp is fixed, and the right clamp fixing device starts to move along the axis direction, and the two ends of the elliptical tube are taken and tightened.

[0059] (3) Turn on the power and start heating. When the infrared temperature measurement system feedbacks that the temperature of the oval tube reaches 650°C, keep it warm for 5 minutes.

[0060] (4) While maintaining the tension, the left and right clamps start to rotate along the normal direction of the section, so that the sections at both ends of the oval tube overlap as much as possible.

[0061] (5) Turn off the power, and air-cool the titanium alloy oval tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com