A kind of ultraviolet-excited fluorescent normal temperature curing phosphate anti-corrosion coating and preparation method thereof

A technology of curing at room temperature and anti-corrosion coating, applied in anti-corrosion coatings, luminescent coatings, alkali metal silicate coatings, etc., can solve the problems of high maintenance cost of light-emitting components, and achieve long-lasting fluorescence, easy construction, and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

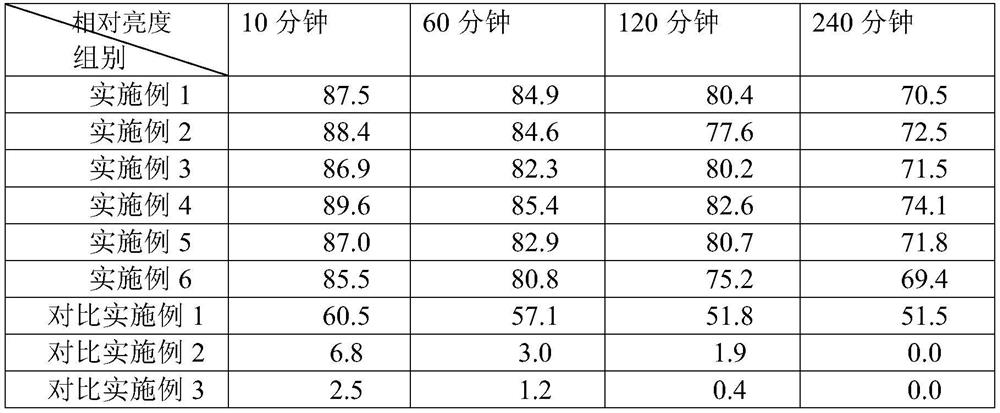

Examples

Embodiment 1

[0028] An ultraviolet-excited fluorescent normal temperature curing phosphate anti-corrosion coating, comprising the following components: 30 parts of potassium dihydrogen phosphate, 15 parts of magnesium oxide, 5 parts of aluminum oxide, 2 parts of zinc dioxide, 2 parts of zirconia, and manganese dioxide 2 parts, 5 parts potassium silicate, 5 parts sodium silicate, 15 parts zinc hydroxide, 5 parts europium trioxide, 8 parts fumed silica, 2 parts silica gel, 2 parts sodium tetraborate, 90 parts water .

[0029] A preparation method of ultraviolet-excited fluorescent normal temperature curing phosphate anti-corrosion coating, comprising the following steps:

[0030] 1) Preparation of phosphate colloid: fully mix and stir 30 parts of potassium dihydrogen phosphate, 5 parts of potassium silicate and 5 parts of sodium silicate, then add 50 parts of water and stir evenly, fully carry out the hydrolysis reaction, and the temperature of the hydrolysis reaction is 20 ° C , the reacti...

Embodiment 2

[0038]A fluorescent anti-corrosion coating, comprising the following components: 25 parts of sodium dihydrogen phosphate, 20 parts of magnesium oxide, 3 parts of zinc dioxide, 2 parts of zirconia, 3 parts of manganese dioxide, 5 parts of potassium silicate, and calcium silicate 5 parts, 15 parts of manganese hydroxide, 3 parts of terbium trioxide, 6 parts of fumed silica, 2 parts of silica gel, 2 parts of potassium tetraborate, and 60 parts of water.

[0039] A preparation method of fluorescent anti-corrosion coating, comprising the following steps:

[0040] 1) Preparation of phosphate colloid: fully mix and stir 25 parts of sodium dihydrogen phosphate, 5 parts of potassium silicate and 5 parts of calcium silicate, then add 30 parts of water and stir evenly, fully carry out hydrolysis reaction, and the temperature of hydrolysis reaction is 25°C , the reaction time is 1h;

[0041] 2) Admixture: add 6 parts of fumed silica, 2 parts of silica gel, and 2 parts of potassium tetrab...

Embodiment 3

[0048] A fluorescent anti-corrosion coating, comprising the following components: 10 parts of potassium monohydrogen phosphate, 20 parts of potassium dihydrogen phosphate, 20 parts of magnesium oxide, 5 parts of aluminum oxide, 3 parts of magnesium hydroxide, 2 parts of zirconia, and potassium silicate 5 parts, magnesium silicate 5 parts, aluminum silicate 5 parts, strontium hydroxide 20 parts, cerium oxide 5 parts, fumed silica 8 parts, aluminum silicate 2 parts, potassium metaborate 1 part, sodium metaborate 1 part, 110 parts of water.

[0049] A preparation method of fluorescent anti-corrosion coating, comprising the following steps:

[0050] 1) Preparation of phosphate colloid: fully mix and stir 10 parts of potassium monohydrogen phosphate, 20 parts of potassium dihydrogen phosphate, 5 parts of potassium silicate, 5 parts of magnesium silicate and 5 parts of aluminum silicate, and then add 60 parts of water and stir Evenly, the hydrolysis reaction is fully carried out, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com