Star-structure polycarboxylic acid dispersing agent as well as preparation method and application thereof

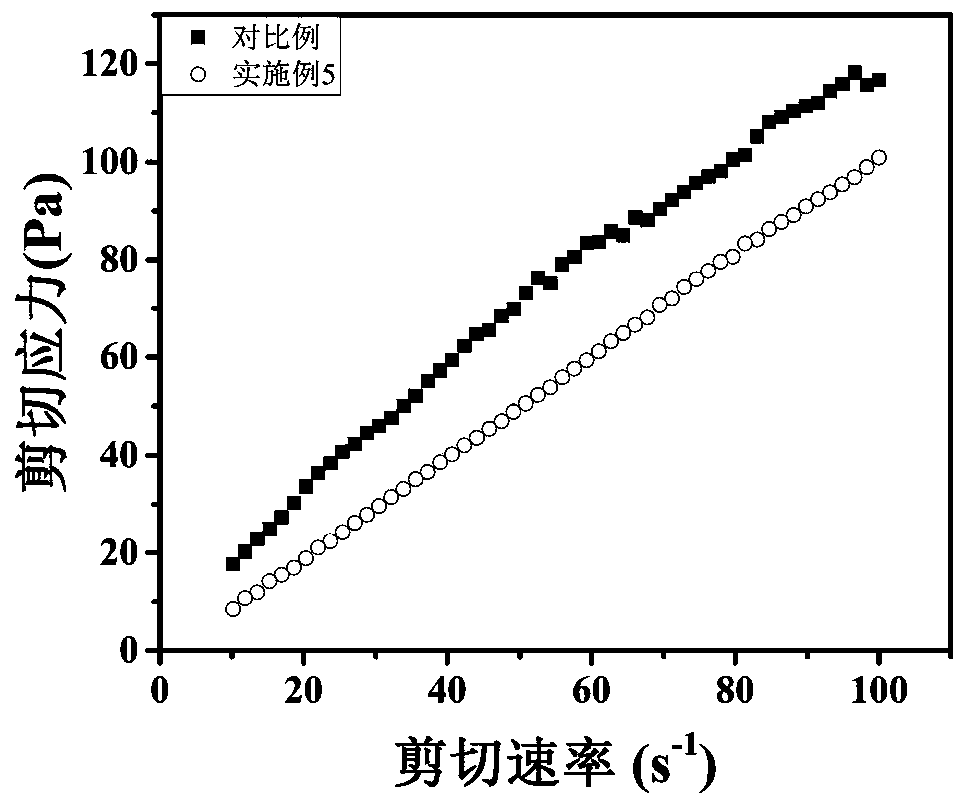

A technology of star-shaped structure and polycarboxylic acid, applied in the field of concrete admixture, can solve the problems of high viscosity of concrete and insufficient initial dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1) Mix 120g of ethylenediamine and 0.12g of sodium hydroxide evenly, then vacuumize, under the protection of nitrogen, slowly raise the temperature to 80°C, slowly introduce 352g of ethylene oxide, keep the temperature for 2 hours, and cool down to obtain a compound with multiple amine groups The polyether macromonomer C.

[0068] 2) Put 14.8g of polyether macromonomer C with multiple amino groups obtained in step (1) and 19.6g of maleic anhydride under nitrogen protection, heat up to 60°C, add 0.02g of p-toluenesulfonic acid, and slowly heat up to 80°C, keep the temperature constant for 6h, and then lower the temperature to obtain the acylated product—polymerizable star-shaped macromonomer E.

[0069] 3) In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen inlet tube, add 200g of polyethylene glycol monomethyl ether acrylate (Mn=500g / mol), and simultaneously add 133.3g of deionized water, While stirring, the reaction vessel was p...

Embodiment 2

[0071] 1) Mix 103g of diethylenetriamine and 0.21g of potassium hydroxide uniformly and then vacuumize it. Under the protection of nitrogen, slowly raise the temperature to 120°C. After slowly feeding 580g of propylene oxide, keep the temperature for 1.5h, and cool down to obtain a compound with multiple amines. Based polyether macromonomer C.

[0072] 2) 13.9g of the polyether macromonomer C with multiple amino groups obtained in step (1) and 17.2g of methacrylic acid were heated up to 60°C under nitrogen protection, and after adding 0.03g of benzenesulfonic acid, the temperature was slowly raised to 110°C, constant temperature for 4h, cooling down to obtain the acylated product—polymerizable star-shaped macromonomer E.

[0073]3) In a glass reactor equipped with a thermometer, stirrer, dropping funnel and nitrogen inlet tube, add 200g polyethylene glycol monomethyl ether methacrylate (Mn=1000g / mol), and add 300g deionized water at the same time , While stirring, the reactio...

Embodiment 3

[0075] 1) Mix 103g of diethylenetriamine and 0.52g of sodium methoxide uniformly, then vacuumize, under the protection of nitrogen, slowly raise the temperature to 100°C, slowly introduce 1160g of propylene oxide, keep the temperature for 2 hours, and cool down to obtain a compound with multiple amine groups. Polyether macromonomer C.

[0076] 2) 13.9g of polyether macromonomer C with multiple amino groups obtained in step (1) and 30g of dimethacrylic acid were heated to 60°C under nitrogen protection, and after adding 0.44g of concentrated sulfuric acid, the temperature was slowly raised to 100 ℃, keep the temperature for 5 hours, and cool down to obtain the acylated product—polymerizable star-shaped macromonomer E.

[0077] 3) In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen inlet tube, add 200g of polyethylene glycol monomethyl ether methacrylate (Mn=2000g / mol), and simultaneously add 200g of deionized water , While stirring, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com