Anaerobic forward osmosis membrane bioreactor process for coupling electrochemical oxidation of ammonia nitrogen

A bioreactor and forward osmosis membrane technology, applied in the field of environmental engineering, can solve the problem of high ammonia nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

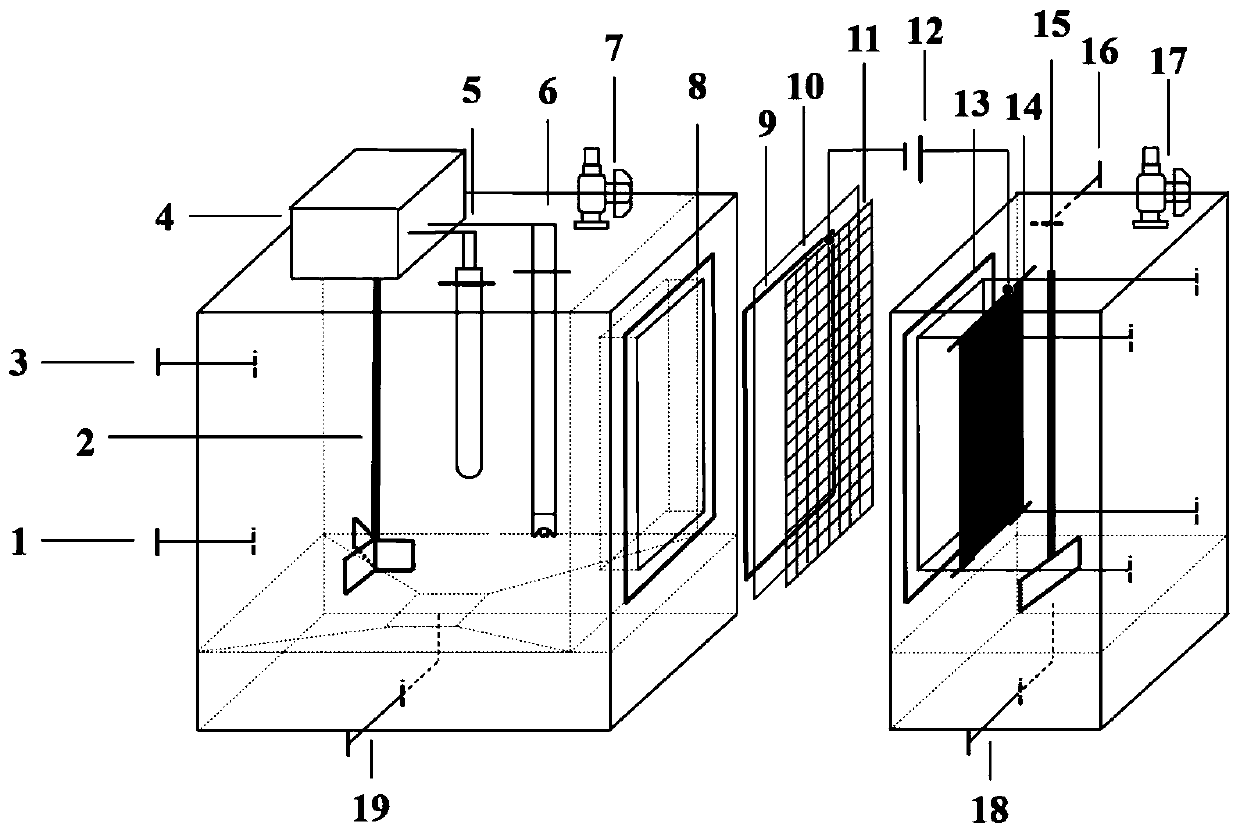

[0022] An anaerobic forward osmosis membrane bioreactor coupled with electrochemical oxidation of ammonia nitrogen, the anaerobic activated sludge is placed at the bottom of the anaerobic sludge mixture chamber 19, and stirred and mixed at a speed of 60 r / min. The two chambers are separated by a forward osmosis membrane. During operation, the temperature of the control system is 30-35°C, pH=6.5-8, the influent COD load is 0.45-1.82kg / m3·d, and the influent COD:N:P ratio is 200:5:1; It is 0.5M NaCl solution; the catalytic anode uses titanium metal mesh to coat the ruthenium iridium tin active layer electrode (Ti / RuO 2 -IrO 2 -SnO 2 ), the cathode is SS316 stainless steel mesh. The cathode and anode plates are placed in parallel with a lateral spacing of 0.5 cm.

[0023] Main substrate concentration: COD:N:P ratio in influent water is 200:5:1.

[0024] The simulated wastewater enters the reactor from the bottom through the water inlet 1, and realizes uniform water distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com