A monolithic catalyst having perovskite oxide skeleton and preparation method thereof

A technology of perovskite oxides and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. change, increase the cost of catalyst preparation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

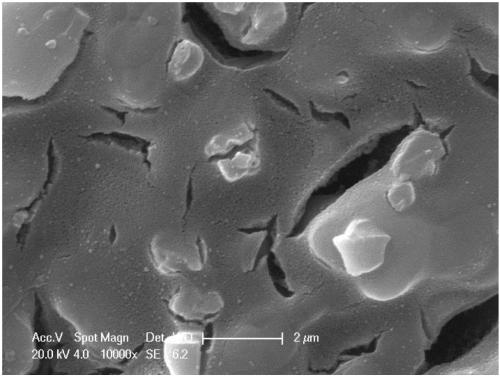

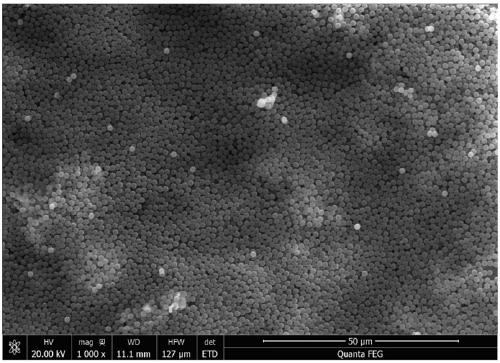

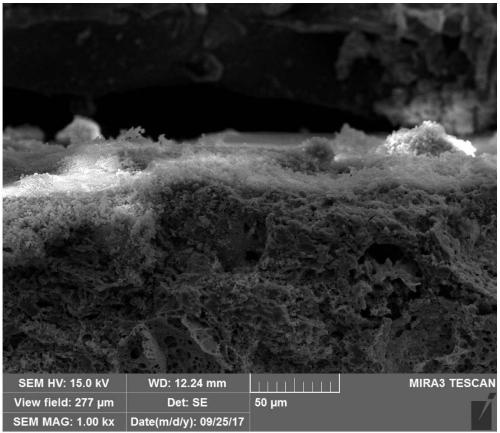

[0051] This embodiment provides a three-dimensional ordered macroporous perovskite La 0.8 Sr 0.2 CoO 3 The method for growing the skeleton to the surface of the cordierite honeycomb ceramics, the specific steps are as follows:

[0052] 1. Washing of cordierite carrier

[0053] Cut commercial cordierite honeycomb ceramics (1mm×1mm square channel) into cube-shaped samples with a size of 1cm×1cm×1cm, and then ultrasonically clean them with distilled water, hexane, acetone, and ethanol in sequence, and the cleaning time for each solvent is 10min; then put the cleaned honeycomb ceramic carrier in an oven at 80°C to dry for 4h to obtain a clean honeycomb ceramic substrate for use;

[0054] 2. Preparation of perovskite precursor colloidal solution

[0055] Dissolve 1.92mM lanthanum nitrate, 0.48mM strontium nitrate, and 2.4mM cobalt nitrate in a mixed solvent of 15mL ethylene glycol and 10mL methanol, ultrasonically dissolve and disperse it completely, then stir continuously at r...

Embodiment 2

[0070] In order to further evaluate the catalytic activity of the catalyst of the present invention, the present invention uses a gas-phase catalytic oxidation activity evaluation experiment for evaluation.

[0071] Methane (CH 4 ) The catalytic combustion activity evaluation test is carried out in a fixed-bed reactor simulated by a quartz tube with a diameter of 23 mm. 700 mg of the monolithic catalyst (about 60-70 mg of perovskite active components) was loaded into a quartz tube, and the quartz tube was placed in a tube furnace, and the temperature was raised from room temperature to 750° C. by program. The reaction gas composition (volume fraction) is: 1% CH 4 ,20%O 2 ,79%N 2 , the total flow rate is 50mL / min, and the mass space velocity is 43000mL / (g h). The composition of the final reaction tail gas was analyzed online by Fuli GC-9790 gas chromatograph, CH 4 The formula for calculating the conversion rate is:

[0072] CH 4 Conversion rate (%) = (import CH 4 Peak A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com