Dairy product and preparation process thereof

A preparation process and technology of dairy products, applied in the direction of dairy products, milk preparations, applications, etc., can solve problems such as poor stability, easy oil slicks and stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

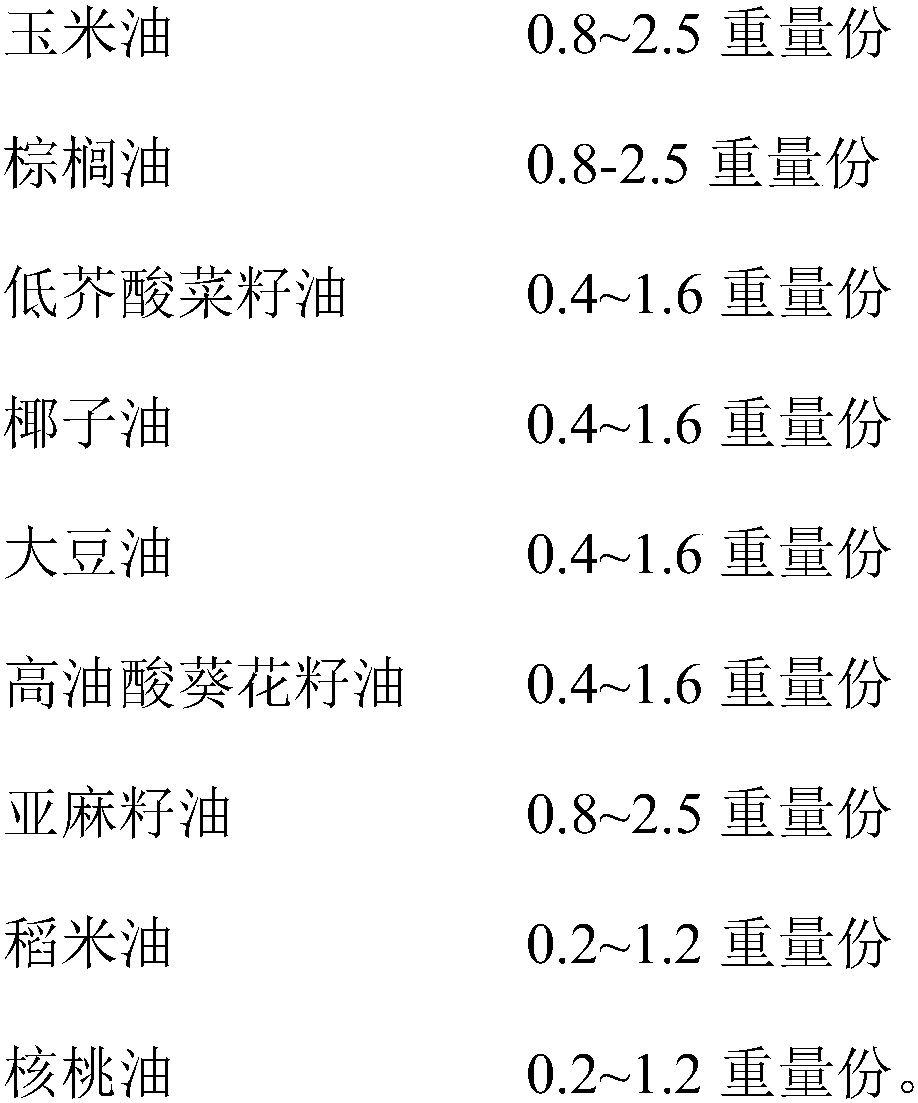

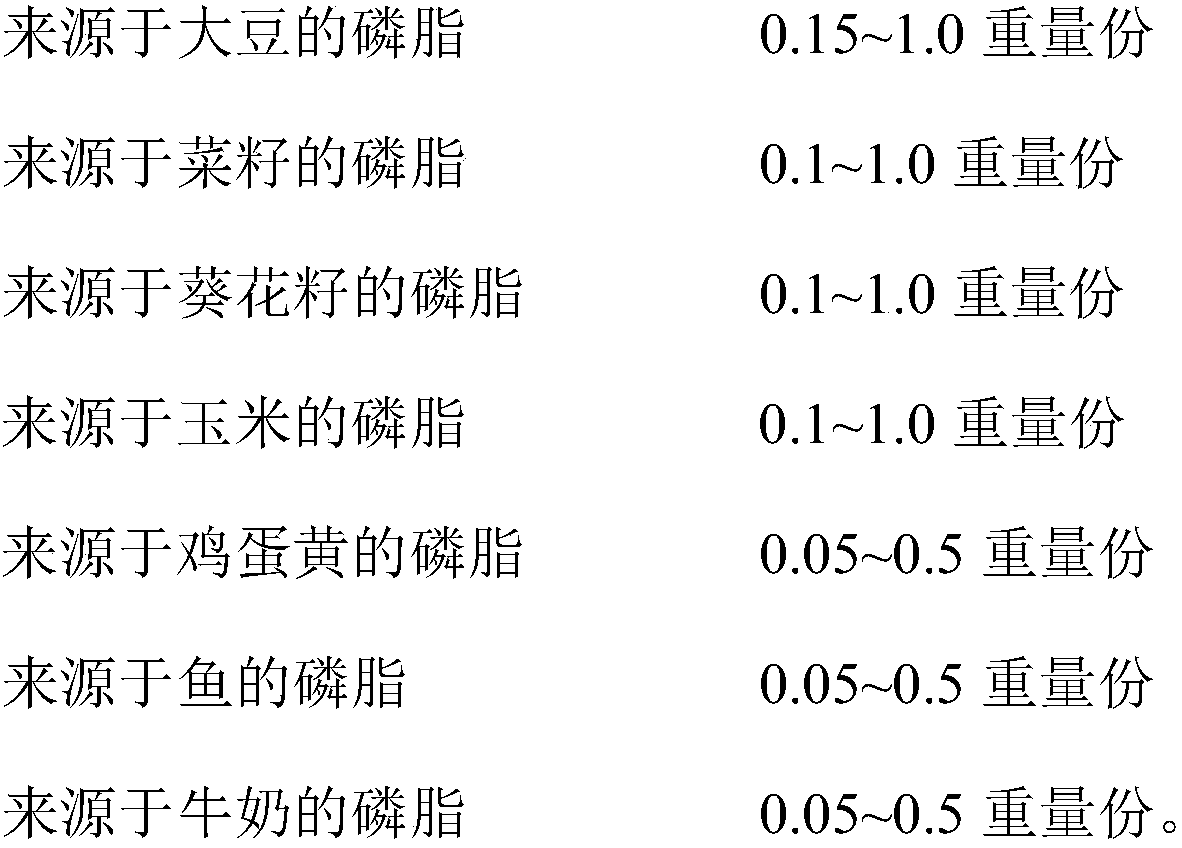

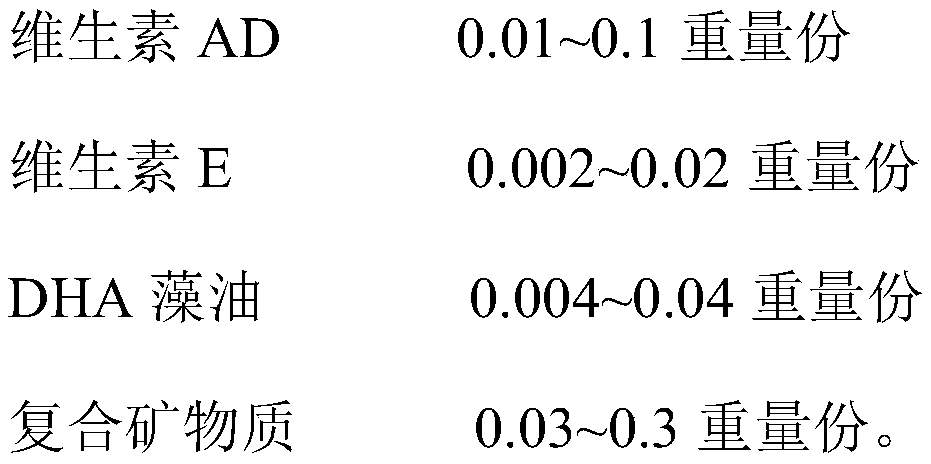

Method used

Image

Examples

Embodiment 1

[0079] This embodiment provides a dairy product and its preparation process. The dairy product is made up of the following raw materials, as shown in Table 1,

[0080] Table 1: Raw material composition table

[0081] Element Weight (kg) Element Weight (kg) Element Weight (kg) low fat milk 950.0 lactose 6 Vitamin E 0.05 White sugar 27.0 vegetable oil 80 DHA algae oil 0.09 fructooligosaccharide 15 Phospholipids 1.5 complex minerals 0.3 Galactooligosaccharides 8 Vitamin AD 0.7 essence 2

[0082] Wherein, the vegetable oil is a mixed oil of linseed oil, canola oil, high oleic sunflower oil, soybean oil and rice oil with a mass ratio of 4:2:2:2:1; the phospholipid is soybean phospholipid;

[0083] Vitamin AD is a mixture of vitamin A acetate and vitamin D2;

[0084] Complex minerals are a mixture of L-calcium lactate, ferrous gluconate and zinc gluconate;

[0085] The preparation technology of above-mentioned m...

Embodiment 2

[0097] This embodiment provides a dairy product and its preparation process. The dairy product is made up of the following raw materials, as shown in Table 2,

[0098] Table 2: Raw material composition table

[0099]

[0100]

[0101] Wherein, the vegetable oil is a mixed oil of linseed oil, canola oil, high oleic sunflower oil, soybean oil and rice oil with a mass ratio of 4:2:2:2:1; the phospholipid is sunflower phospholipid;

[0102] Vitamin AD is a mixture of vitamin A acetate, vitamin D2 and vitamin D3;

[0103] Complex minerals are a mixture of calcium carbonate, ferrous lactate and zinc chloride;

[0104] The preparation technology of above-mentioned milk product, comprises the steps:

[0105] (1) Heat 30kg of vegetable oil to 48°C, add 15kg of phospholipids for the first shear, the shear rate of the first shear is 5000rad / min, and the time is 30min, after the vegetable oil and phospholipid after the first shear treatment are mixed The feed liquid is heated to...

Embodiment 3

[0116] This embodiment provides a dairy product and its preparation process. The dairy product is made up of the following raw materials, as shown in Table 3,

[0117] Table 3: Raw material composition table

[0118] Element Weight (kg) Element Weight (kg) Element Weight (kg) low fat milk 350.0 lactose 36 Vitamin E 0.16 White sugar 5 vegetable oil 53 DHA algae oil 0.2 fructooligosaccharide 18 Phospholipids 3.5 complex minerals 1 Galactooligosaccharides 2 Vitamin AD 1.0 essence 0.4

[0119] Wherein, the vegetable oil is a mixed oil of linseed oil, canola oil, high oleic sunflower oil, soybean oil and rice oil with a mass ratio of 4:2:2:2:1; the phospholipid is corn lecithin;

[0120] Vitamin AD is a mixture of vitamin A acetate, vitamin D2 and vitamin D3;

[0121] Complex minerals are a mixture of calcium carbonate, iron citrate and zinc sulfate;

[0122] The preparation technology of above-mentioned milk p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com