A method for improving the quality of polycarbonate-polyether polyol produced by liquid phase method

A technology of polyether polyol and polycarbonate, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased production cost of polymers, reduced heat and mass transfer efficiency, and reduced catalyst activity, and achieves inhibition Formation of polyether chain links and cyclic carbonates, improvement of mass and heat transfer capabilities and effects, and effects of increasing the content of carbonate units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

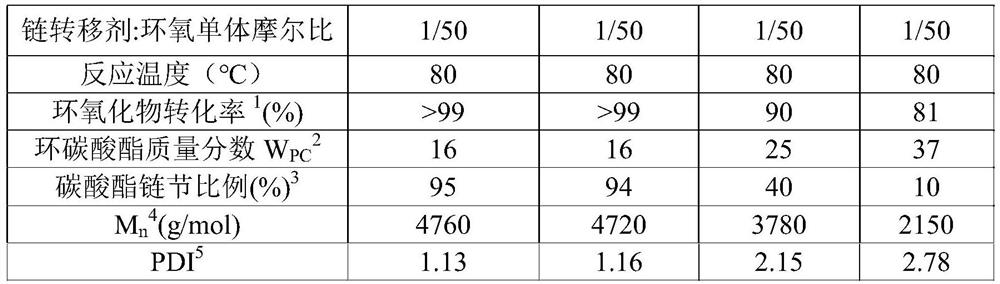

Embodiment 1

[0048] A method for improving the quality of polycarbonate-polyether polyol produced by liquid phase method,

[0049] Include the following steps:

[0050] (1) The raw material is pumped in from the inlet of the straight tube reactor, and the straight tube reactor includes a heating segment group and a cooling segment group, and the heating segment group is placed at the end of the straight tube reactor At the inlet end, the cooling segment group is placed at the outlet end of the straight pipe reactor, and the heating segment group includes a first heating segment group and a second heating segment group, and the first heating segment group and the The second heating section group is connected in series, and the raw material includes a chain transfer agent, an epoxy compound, a catalyst and carbon dioxide, so that in the presence of the catalyst, the chain transfer agent, the epoxy compound and carbon dioxide are contacted in the first heating section group, Thereby carry ou...

Embodiment 2

[0080] Embodiment 2 With reference to Example 1, the difference is that the outlet end of the first heating section group has a pipeline connected to the inlet end of the first heating section group, so that part or all of the reaction liquid flow is circulated in the first heating section group. In that, by controlling the induction period of the polymerization reaction, the reaction rate is accelerated, the reaction time is shortened, the preactivation of carbon dioxide, initiator and epoxy monomer is promoted, and the proportion of polycarbonate chain units in the product is increased.

Embodiment 3

[0090] Embodiment 3 With reference to Embodiment 1, the difference is that a first intermediate device is provided between the first heating segment group and the second heating segment group, and the first intermediate device is connected to a carbon dioxide pipeline through a pipeline, so that the The medium pressure in the straight tube tubular reactor is adjusted to 2-6MPa; the purpose is to control the CO of the polymerization reaction 2 pressure, so that in the reaction, there is enough CO 2 It can participate in the polymerization reaction, which is beneficial to the reaction of polycarbonate-polyether polyol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com