Red food based compound small molecule peptide and application in body oxidative damage repair

A small molecular peptide and red food technology, applied in the field of red food compound small molecular peptides, can solve the problems of weak damage repair effect, little attention to protein components, and side effects, etc., to repair cell defects, and the preparation method is simple and practical , less toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

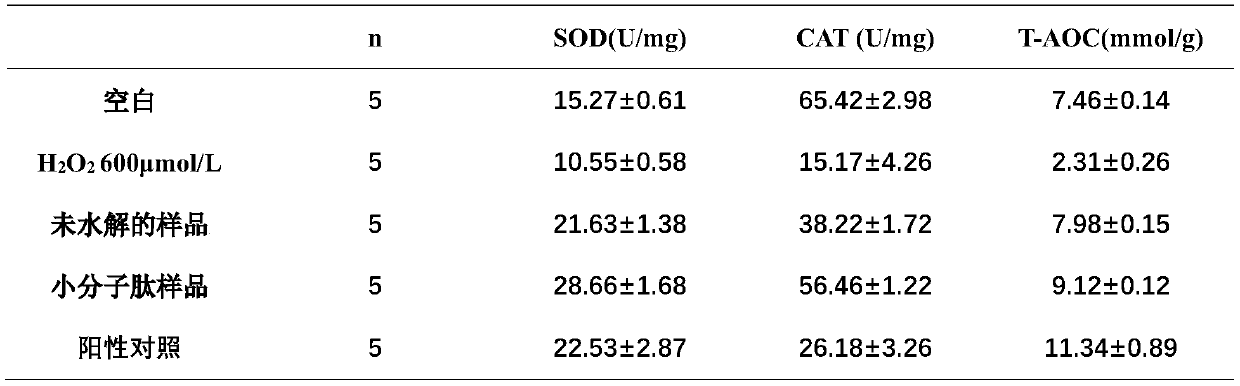

Image

Examples

Embodiment 1

[0030] 1. Weigh 300g red bean, 300g red rice, 300g red barley, 300g red pumpkin, 200g peanut, 150g hawthorn, 150g brown sugar, 100g jujube, 50g red quinoa, 30g medlar, 30g hericium erinaceus powder, 30g poria, Roselle 30g and red ginseng 30g;

[0031] 2. Preparation of raw material powder: Weigh the above materials, wash them with water, dry them to remove water, and use a wall breaking machine to break the walls and crush them for later use;

[0032] 3. Preparation of fermented product: Pour the raw material powder into the fermenter and add baker's yeast powder; material: baker's yeast powder volume ratio=100:1, seal for 1 hour to ferment, and collect the fermented product for subsequent use;

[0033] 4. Preparation of enzymolysis products: the fermentation broth is placed in a mixed enzymolysis reaction tank, the temperature is raised to 53°C, papain is added (material:enzyme volume ratio=100:1), the reaction temperature is between 45°C, and the pH is controlled at 6.0, re...

Embodiment 2

[0036] 1. Weigh 250g red bean, 250g red rice, 250g red barley, 250g red pumpkin, 150g peanut, 100g hawthorn, 100g brown sugar, 70g jujube, 40g red quinoa, 20g medlar, 20g Hericium erinaceus powder, 20g poria, 20g of roselle and 20g of red ginseng;

[0037] 2. Preparation of raw material powder: Weigh the above materials, wash them with water, dry them to remove water, and use a wall breaking machine to break the walls and crush them for later use;

[0038] 3. Preparation of fermented product: Pour the raw material powder into the fermenter and add baker's yeast powder; material: baker's yeast powder volume ratio=85:0.8, seal for 1 hour to ferment, and collect the fermented product for subsequent use;

[0039] 4. Preparation of enzymolysis products: the fermentation broth is placed in a mixed enzymolysis reaction tank, the temperature is raised to 53°C, papain is added (material:enzyme volume ratio=85:0.6), the reaction temperature is between 55°C, and the pH is controlled at ...

Embodiment 3

[0042] 1. Weigh 200g red bean, 200g red rice, 200g red barley, 200g red pumpkin, 150g peanut, 100g hawthorn, 100g brown sugar, 100g jujube, 30g red quinoa, 10g medlar, 10g Hericium erinaceus powder, 10g poria, Roselle 10g and red ginseng 10g;

[0043] 2. Preparation of raw material powder: Weigh the above materials, wash them with water, dry them to remove water, and use a wall breaking machine to break the walls and crush them for later use;

[0044] 3. Preparation of fermented product: Pour the raw material powder into the fermenter and add baker's yeast powder; material: baker's yeast powder volume ratio=70:0.5, seal for 1 hour to ferment, and collect the fermented product for subsequent use;

[0045] 4. Preparation of enzymolysis products: the fermentation broth is placed in a mixed enzymolysis reaction tank, the temperature is raised to 53°C, papain is added (material:enzyme volume ratio=70:0.3), the reaction temperature is between 45°C, and the pH is controlled at 5.0, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com