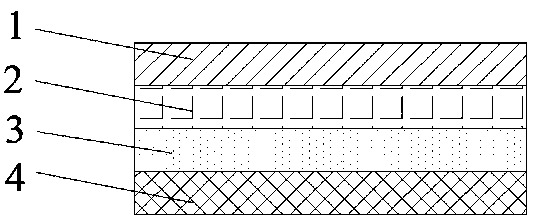

Electrostatic adsorption flame-retardant film

A technology of flame-retardant film and electrostatic adsorption, which is applied in the field of decorative materials, can solve the problems of air bubbles produced by film and plastic film, small adhesion, difficult to attach, and promote fire spread, so as to achieve easy attachment and prevent glass from breaking and splashing. people, saving air-conditioning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation of electrostatic adsorption flame retardant film:

[0034] (1) Add polyethylene terephthalate and polyvinyl chloride into the melting machine, heat to melt, after mixing evenly, add homogeneous oil, antioxidant, liquid silica gel and solvent, mix evenly and add Transfer to the high-speed disperser to prepare the heat-insulating base material, inject the heat-insulating base material into the injection mold, keep the pressure at 5-10MPa for 5-10 minutes, and then lower it to room temperature for demoulding to obtain the heat-insulating base .

[0035] (2) The degree of polymerization of ammonium polyphosphate is greater than 1000. Stir and mix bisphenol A epichlorohydrin resin, ammonium polyphosphate and melamine cyanurate at a high temperature of 90°C, add a curing agent, and pour it into the mold. Cured at 50°C for 8 hours, then extruded and stretched to make a flame retardant layer.

[0036] (3) Evenly disperse 2% nano-titanium dioxide, 1.5% nano-alumi...

Embodiment 2

[0041] A preparation of electrostatic adsorption flame retardant film:

[0042] (1) Add polyethylene terephthalate and polyvinyl chloride into the melting machine, heat to melt, after mixing evenly, add homogeneous oil, antioxidant, liquid silica gel and solvent, mix evenly and add Transfer to the high-speed disperser to prepare the heat-insulating base material, inject the heat-insulating base material into the injection mold, keep the pressure at 5-10MPa for 5-10 minutes, and then lower it to room temperature for demoulding to obtain the heat-insulating base .

[0043] (2) The degree of polymerization of ammonium polyphosphate is greater than 1000. Stir and mix bisphenol F type epichlorohydrin resin, ammonium polyphosphate, melamine cyanurate, anhydrous sodium silicate and aluminum borate at a high temperature of 90°C, Add a curing agent, pour into the mold, cure at 50°C for 8 hours, and then extrude and stretch to make a flame-retardant layer.

[0044] (3) Evenly disperse...

Embodiment 3

[0048] A preparation of electrostatic adsorption flame retardant film:

[0049] (1) Add polyethylene terephthalate and polyvinyl chloride into the melting machine, heat to melt, after mixing evenly, add homogeneous oil, antioxidant, liquid silica gel and solvent, mix evenly and add Transfer to the high-speed disperser to prepare the heat-insulating base material, inject the heat-insulating base material into the injection mold, keep the pressure at 5-10MPa for 5-10 minutes, and then lower it to room temperature for demoulding to obtain the heat-insulating base .

[0050] (2) The degree of polymerization of ammonium polyphosphate is greater than 1000. Stir and mix alicyclic epoxy resin, ammonium polyphosphate, melamine cyanurate, anhydrous potassium silicate and zinc borate at a high temperature of 90°C, and add a curing agent , and then poured into the mold, cured at 50 ° C for 8 hours, and then extruded and stretched to make a flame-retardant layer.

[0051] (3) Evenly disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com